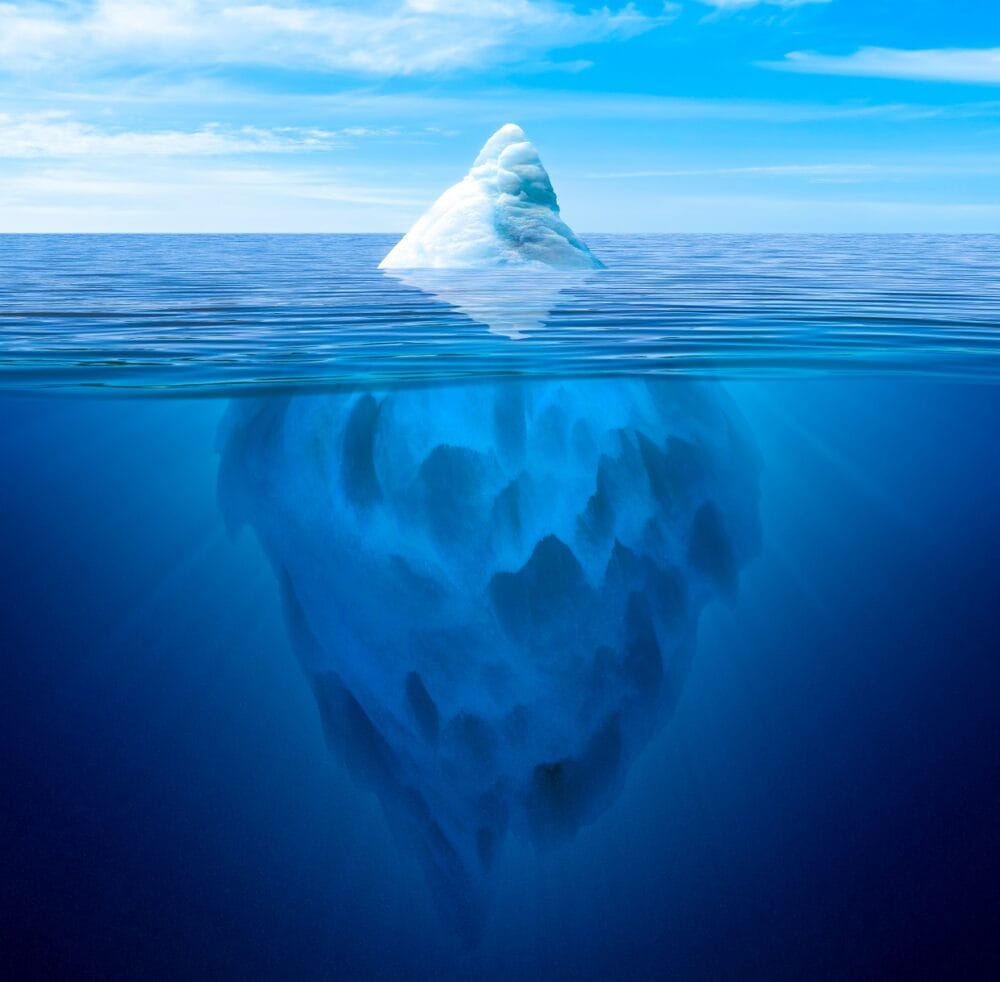

In the fast-paced industry of subcontract precision engineering, where the surface of business challenges often masks the complexity below, the analogy of the iceberg proves strikingly accurate.

Much like the iceberg’s hidden mass beneath the waterline, the vast majority of operational hurdles remain unseen by top-level management, residing instead in the domain of shop floor employees. This revelation underscores the pivotal role of production control software in steering the course of a successful company.

Many subcontract precision engineers are now able to identify and tackle these challenges head-on, as a result of implementing PSL Datatrack in their businesses. PSL Datatrack is a flexible, modular production control system which helps users to streamline their entire production process, covering all the steps required to win and manufacture a job whilst saving them administration time and costs.

Let’s dive into how each area of the software helps users to conquer the hidden depths of their organisations:

This is where precision meets planning. The Quotations module, often referred to as the software equivalent of setting a machine tool, enables fast and accurate calculation of the sales price of a component, assembly or product assembled from a Bill Of Materials (BOM).

Application of the Quotations module provides top-level management with insights into project feasibility and resource allocation, enabling informed decision-making to drive profitability and growth.

From Works Orders to Assemblies, BOMs to Component Stocks and Deliveries, this section of the system enables the processing of new and repeat orders with ease.

For management personnel, these modules provide real-time visibility into sales performance and production requirements, facilitating strategic planning and resource allocation to optimise profitability.

Encompassing Purchase Orders, Goods Received and Material Stocks, the Purchasing modules manage the ordering of goods and services together with recording of goods received for full traceability.

The Purchasing modules empower top-level management with comprehensive oversight of procurement processes, enabling optimised supply chain efficiency and minimised costs.

Central to streamlined operations, the Planning modules guide each step of the production process with precision and foresight.

For those in charge of scheduling, these advanced tools simplify workflow management to drive productivity and on-time deliveries.

The Shop Floor Data Collection (SFDC) and Time And Attendance modules provide instant progress information, alongside clocked hours, back to top-level management.

SFDC information allows management to compare actual time taken to quoted time, while instant reporting in Time And Attendance can be used to make payroll calculations.

The Contract Review, Gauge Calibration and Non Conformance modules help users adhere to the standards of ISO 9001, AS9100, IATF 16949 and other accreditations with ease.

Quality Managers therefore maintain oversight of quality control processes, ensuring adherence to industry standards and enhanced customer satisfaction.

With five main areas for financial control, this area keeps the cash flowing and the numbers in check, allowing users to focus on what they do best – producing turned parts and machined components!

Making money is the aim of the game, and PSL Datatrack’s financial insights and analysis enable informed decision-making and strategic planning to optimise profitability and financial performance.

Within this domain lie the tools of leadership, notably CRM/Tasks and User Maintenance to control the responsibilities and access rights of employees.

Meanwhile, Status Boards give visibility to real-time Key Performance Indicators (KPIs), providing management with even more control over manufacturing processes.

The backbone of any company’s operation, customer/supplier information and cost centre rules are defined here for use in other areas of the system.

With streamlined administrative processes and centralised data management, the Administration modules inspire confidence that data reused later down the line will be up-to-date and accurate.

Optional extensions to key modules in the form of Document Management, Imaging, Inspection Records and Listing Screens.

These features provide greater usability and reporting capabilities to all staff members in the factory.

In essence, PSL Datatrack serves as a catalyst for innovation and efficiency. A main menu statistics dashboard enables authorised users to drill down into 57 KPIs for quick reference, with more detailed reports available to home in on the detail behind the values.

Our customers benefit from the close working relationships we build and can customise existing reports and Status Boards, or commission new ones, to ensure these outputs show them exactly the information they need to see at the push of a button.

At a time where the iceberg’s submerged mass holds the key to total business efficiency, PSL Datatrack emerges as the solution for subcontract precision engineers. Let’s uncover the hidden depths of success together!

01344 827312 sales@psldatatrack.com