Manual vision systems are important to industry because they combine precision, flexibility, cost-effectiveness, and user control. They play a critical role in quality assurance, prototyping, and low-volume production, making them indispensable tools for maintaining high standards and ensuring the integrity of manufactured products.

The key factors are that they provide precision and accuracy in a flexible, versatile and easy to use format. As they have a lower initial cost compared to automated instruments, they are also very cost effective with a rapid ROI and simpler to maintain. The simplicity of use leads to quicker implementation and usage meaning that consistent quality control is achieved very quickly along with quality control documentation and reporting. This can be achieved by operators that do not have metrology experience freeing up a measurement room where more sophisticated equipment may be used.

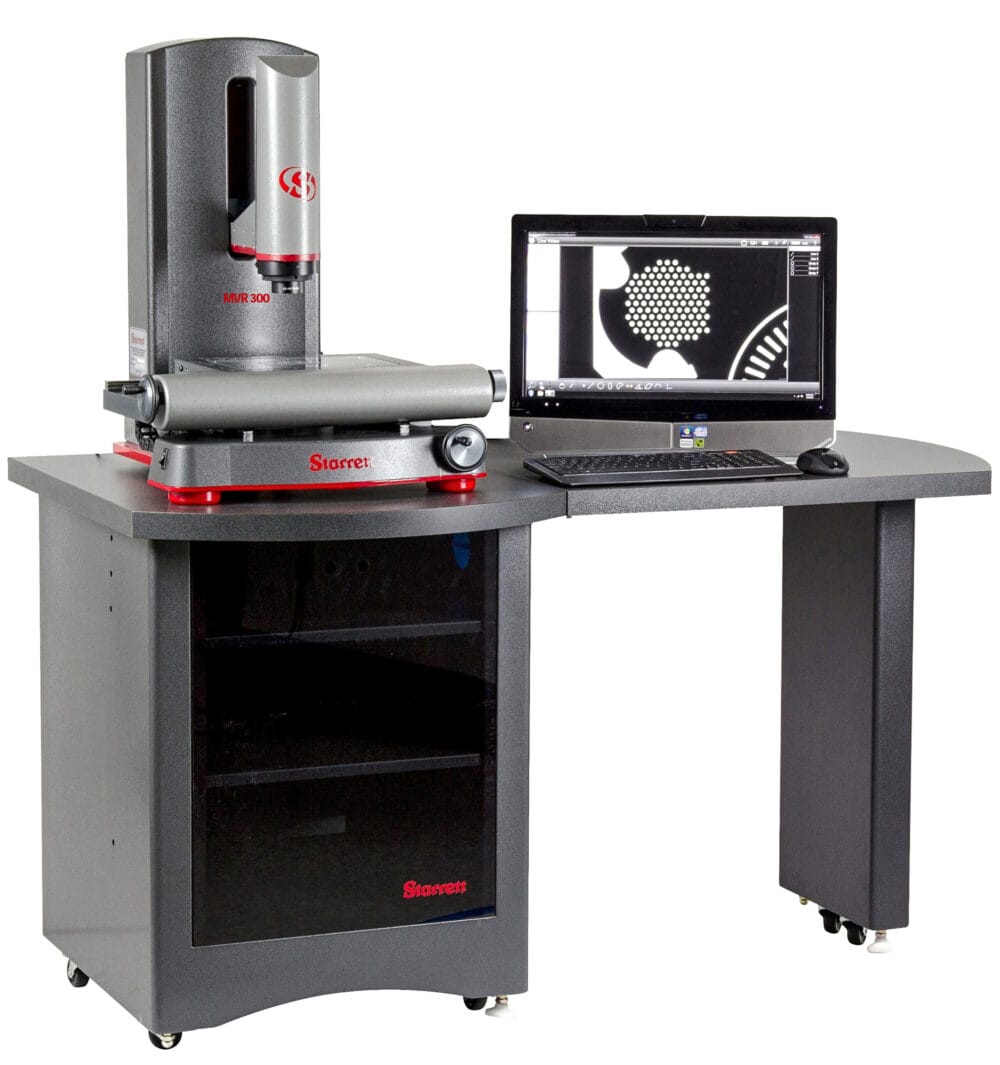

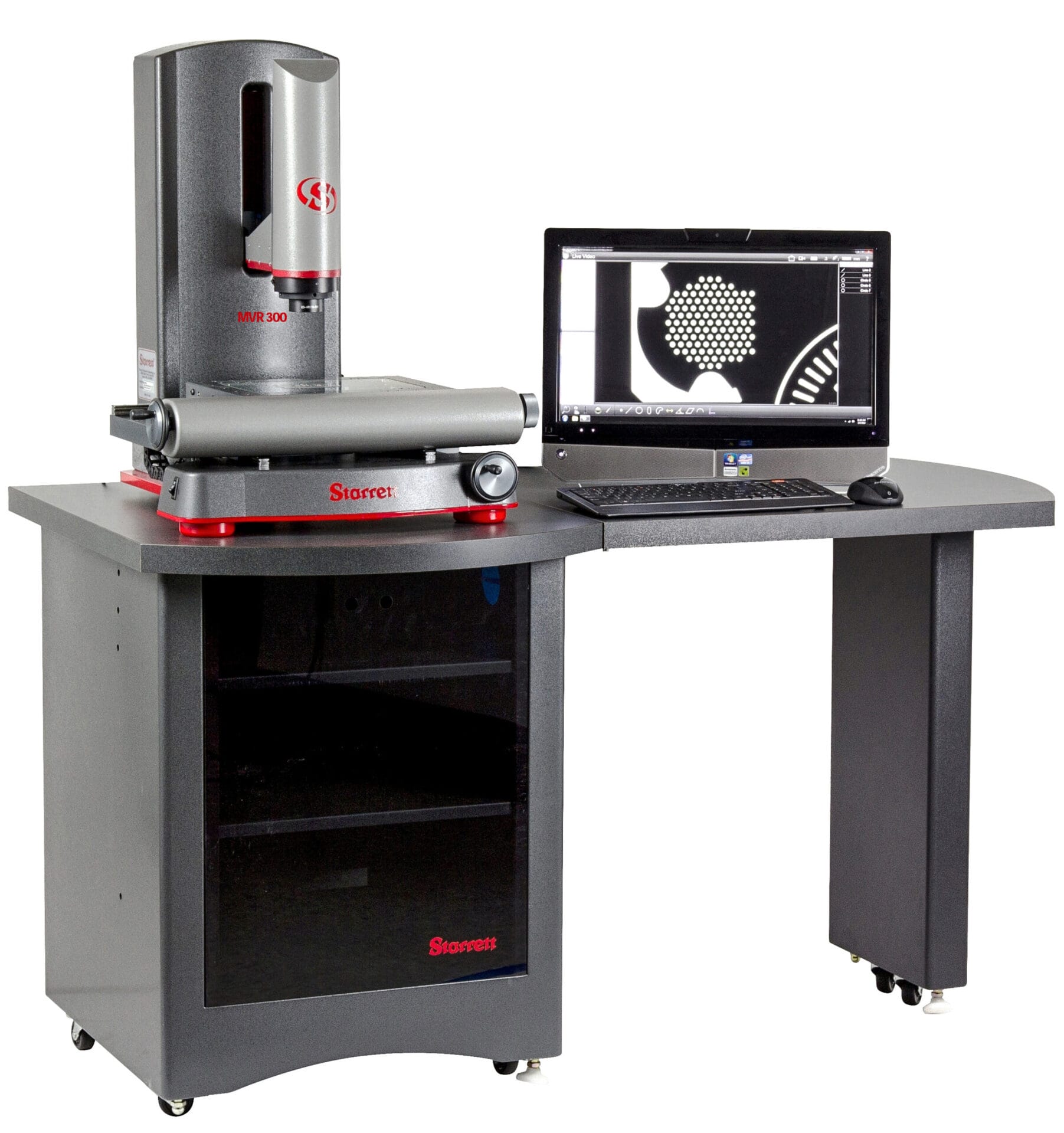

One such instrument is the Starrett MVR300, The MVR300 is a manual vision metrology system designed for precision measurement and inspection tasks. It is manufactured by the L.S. Starrett Company, a well-known producer of precision tools and metrology equipment, the MVR300 is part of comprehensive larger line of vision systems and optical comparators. Here are some key details about the Starrett MVR300:

The MVR300 Manual Vision Metrology System is ideal when quick measurements for quality control are needed. It is available with dedicated zoom optics or a quick-change bayonet lens mount which accepts interchangeable zoom optics or telecentric lenses for micron-level resolution. With a maximum field of view (FOV) of 24mm and seamlessly integrated stage motion, the MVR300 is capable of measuring parts with a length up to 300mm. The operator interface is the MetLogix™ M3 software that displays a live video image of the part plus geometry tools and digital readings. The image of the part can be resized using zoom and measurements can be taken by simply touching a feature on the touch-screen monitor. MVR hardware features include a granite base for maximum stability, precision linear guides for smooth, accurate stage motion and a motorized Z-axis with variable speed control.

The MetLogix™ M3 software also includes the capability for generating customised reports. This automatically generates comprehensive reports based on the measurement data. These reports can include graphical representations, measurement values, tolerances, and pass/fail results.

The inclusion of advanced measurement and reporting software with the Starrett MVR300 enhances its functionality, making it a powerful tool for precision measurement and inspection. The software’s ability to generate detailed reports and manage data efficiently adds significant value, particularly in quality control and regulatory compliance contexts.

Starrett Vision Systems are available in the UK and Europe from Optimax Imaging and Inspection