Titan’s robust flowmeter technology is proving industry recommended in helping beverage manufacturers solve sticky situations.

Soft drinks are typically formulated from a combination of water (which may be carbonated) and a syrup flavouring. Soft drinks manufacturers such as Coca Cola, use a twin dispense system to carefully combine and control each fluid to the exact concentration, ensuring the quality and consistency of flavour that their customers expect.

Dispense systems assure consistent and accurate measures of syrup are supplied during the dispensing of each soft drink. For low viscosity syrups or flavour additives and the diluent being dispensed alongside, both can be controlled and monitored using a turbine flowmeter. Titan’s NSF-Approved 800 series and Beverage flowmeters are widely used within the food and drinks industry for this purpose. These meters are the industry proven choice of many being both effective and reliable flow sensors, with some manufacturers also using them as low-cost alternative flow switches.

As syrup increases in viscosity, positive displacement oval gear flowmeters are used for accurate dosing. Due to the nature of syrup viscosities – sugar free syrup has a lower viscosity than full sugar syrup for example – oval gear flowmeters can address variable viscosity fluids to measure the rate of syrup flow. Where a higher level of accuracy is required, oval gear flow meters can also be calibrated specifically for the syrup type. Dispensing equipment software is then capable of switching between multiple calibrations for an individual flow measurement device, enabling multi-syrup dispense using a single oval gear ‘syrup meter’. So, although temperature and viscosity of syrups are variable parameters, the flow rate of the syrup is ultimately of prime importance to the total volume dispensed to ensure the correct flavour is achieved.

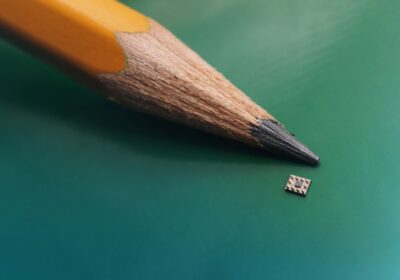

Based on its OG2 model design, Titan Enterprises developed a syrup meter against Coca Cola’s OEM specifications for their multi-soft drink dispense machines. Manufactured in a polymer material as opposed to standard stainless steel, the syrup meter is a low-pressure, low-cost design alternative using food grade polymers. Titan’s oval gear range of flowmeters are capable of measuring flows from 0.01 to 500 l/min, using the low differential pressure across the body to drive a pair of toothed oval gears, one of which contains chemically resistant magnets.

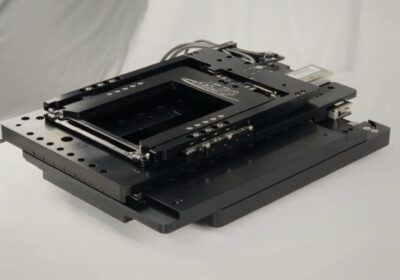

Typically, separate thick syrup and water lines are necessary for soft drink dispensing systems, requiring a flowmeter for each line. However, the beverage industry is evolving fast, with dispensing machines becoming more compact and modular, and capable of adding flavours and CO2 at the point of sale rather than at the bottling plant. This lends itself to OEM designs incorporating the oval gear and turbine mechanics into one flow device designed to fit the space limitations of the customer’s equipment. Titan has developed dual-line flowmeters providing a solution that suits smaller spaces, a single unit being able to measure both non-viscous and viscous liquids side by side at the point of dispense.

“These type of product developments can translate into big environmental and financial savings for the beverage industry”, says Neil Hannay, Senior Development Engineer with Titan Enterprises. “Higher viscosity concentrate of key ingredients requires less transport, energy and CO2 when diluted at point of sale to deliver a fresh end product.” In addition to reducing transport and maintenance costs, venues are able to hold less stock, saving on storage and fridge space.

Visit Titan’s website for further information on Titan’s range of turbine and oval gear flowmeters. To discuss a liquid flow measurement solution for your specific OEM application, contact Titan Enterprises on +44 (0)1935 812790 or sales@flowmeters.co.uk.