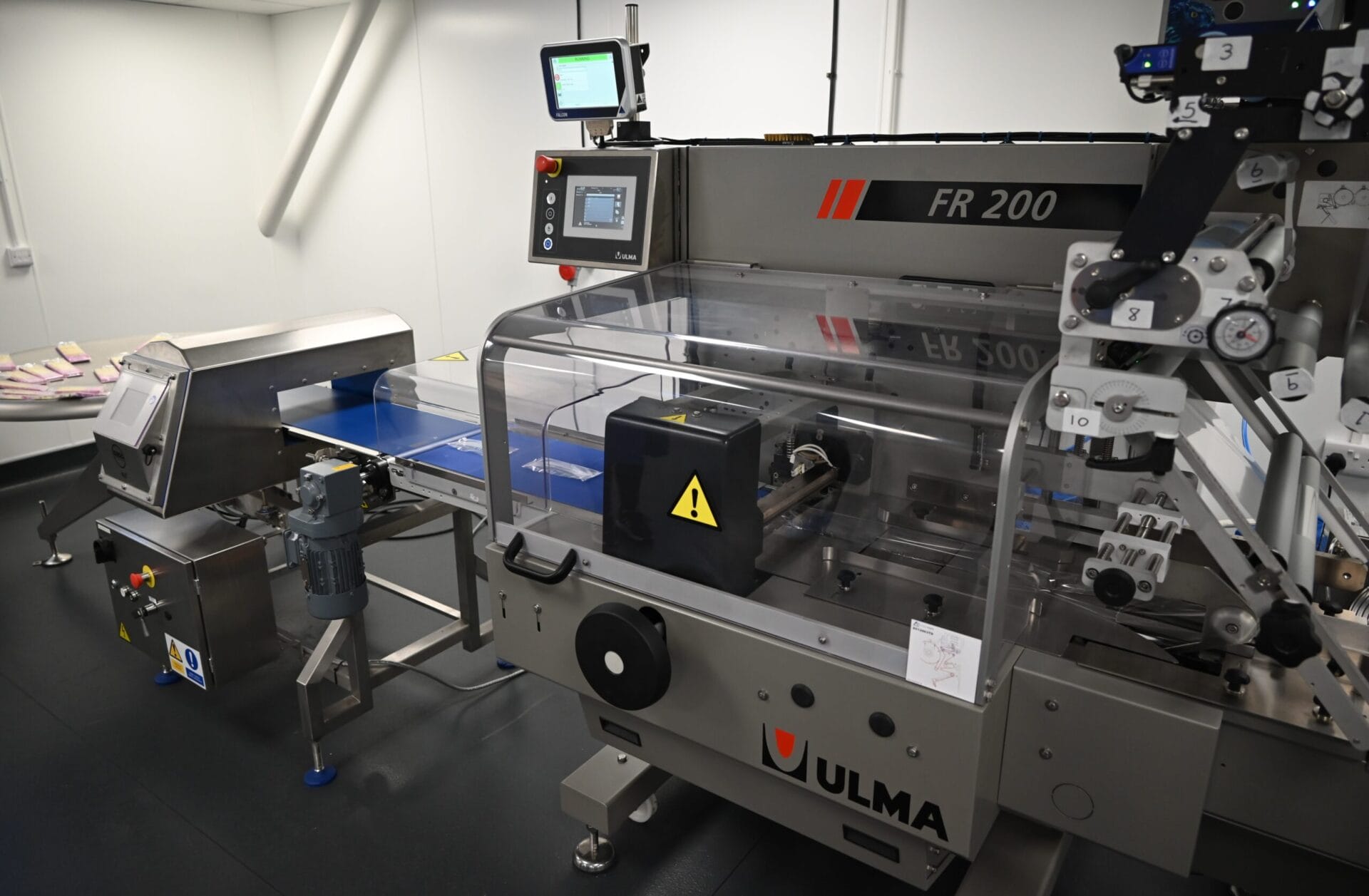

Leading packaging machinery manufacturer, ULMA Packaging, has recently installed one of its advanced FR200 Flow Pack machines at Bon Bon’s Wholesale, a leading provider of luxury confectionery and snacks. The investment has revolutionised Bon Bon’s packaging operations, addressing key challenges and driving significant improvements in efficiency, quality and scalability.

Founded in 2007, Bon Bon’s Wholesale specialises in offering exclusive confectionery products to retail customers, supported by attractive fixtures and effective merchandising strategies. The company’s commitment to providing a straightforward and effective solution to retailers has contributed to its growth and the need for an advanced packaging system.

Bon Bon’s faced several operational challenges due to its rapid growth. Production bottlenecks and inefficiencies in the packaging process made it difficult to meet increasing demand. The labour-intensive nature of chocolate production led to higher costs and a greater risk of human error. Additionally, the existing packaging system lacked the flexibility needed to handle the variety of packaging formats required for their diverse product range.

ULMA Packaging’s FR200 Flow Pack machine emerged as the ideal solution to these challenges. The FR200 offers high-speed and efficient packaging capabilities, significantly boosting production efficiency and enabling Bon Bon’s to meet growing demand effectively. Its precision and uniform packaging capabilities have greatly reduced product damage, enhancing overall product quality and customer satisfaction.

By automating the packaging process, the FR200 minimises the need for manual intervention, allowing Bon Bon’s to re-deploy labour to other critical areas of production. Furthermore, the machine’s versatile design allows it to handle different packaging formats and sizes seamlessly, making it perfect for Bon Bon’s diverse product offerings and supporting its future growth.

Kirsty Firth, joint managing director of Bon Bon’s, said: “The FR200 has transformed our packaging process, allowing us to meet growing demand while maintaining the high quality our customers expect. The flexibility and efficiency of the machine have been game-changers for our operations.”

The implementation of ULMA Packaging’s FR200 Flow Pack machine has proven to be a pivotal move for Bon Bon’s Wholesale. The advanced technology, automation and flexibility of the FR200 have not only resolved existing challenges but also positioned Bon Bon’s for sustained growth and success.

ULMA will be showcasing the FR200 at this year’s PPMA Show 2024, taking place from 24-26 September 2024 at Hall 5, NEC – Birmingham, exhibiting on stand B20.

More information on ULMA Packaging’s flow pack range can be found here.