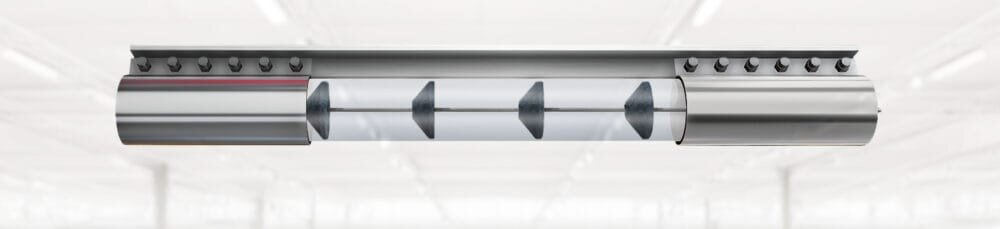

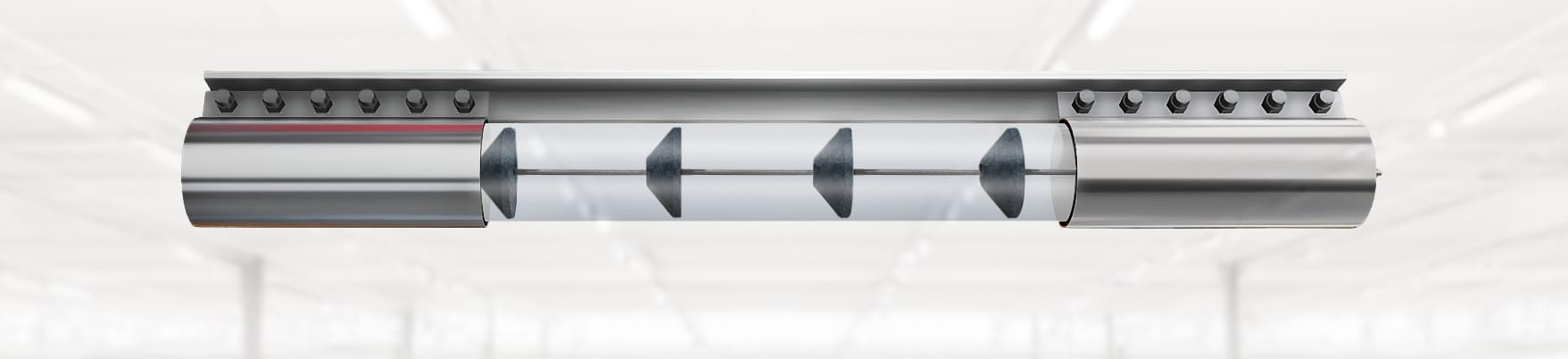

Cablevey Conveyors, part of Automated Handling Solutions (AHS), the leading provider of automation solutions and specialised material handling equipment, has announced the launch of its new metal-detectable cable assemblies for tubular drag conveyor systems. The innovative product is designed to meet the evolving needs of the food processing and material handling industries, providing enhanced safety and operational efficiency.

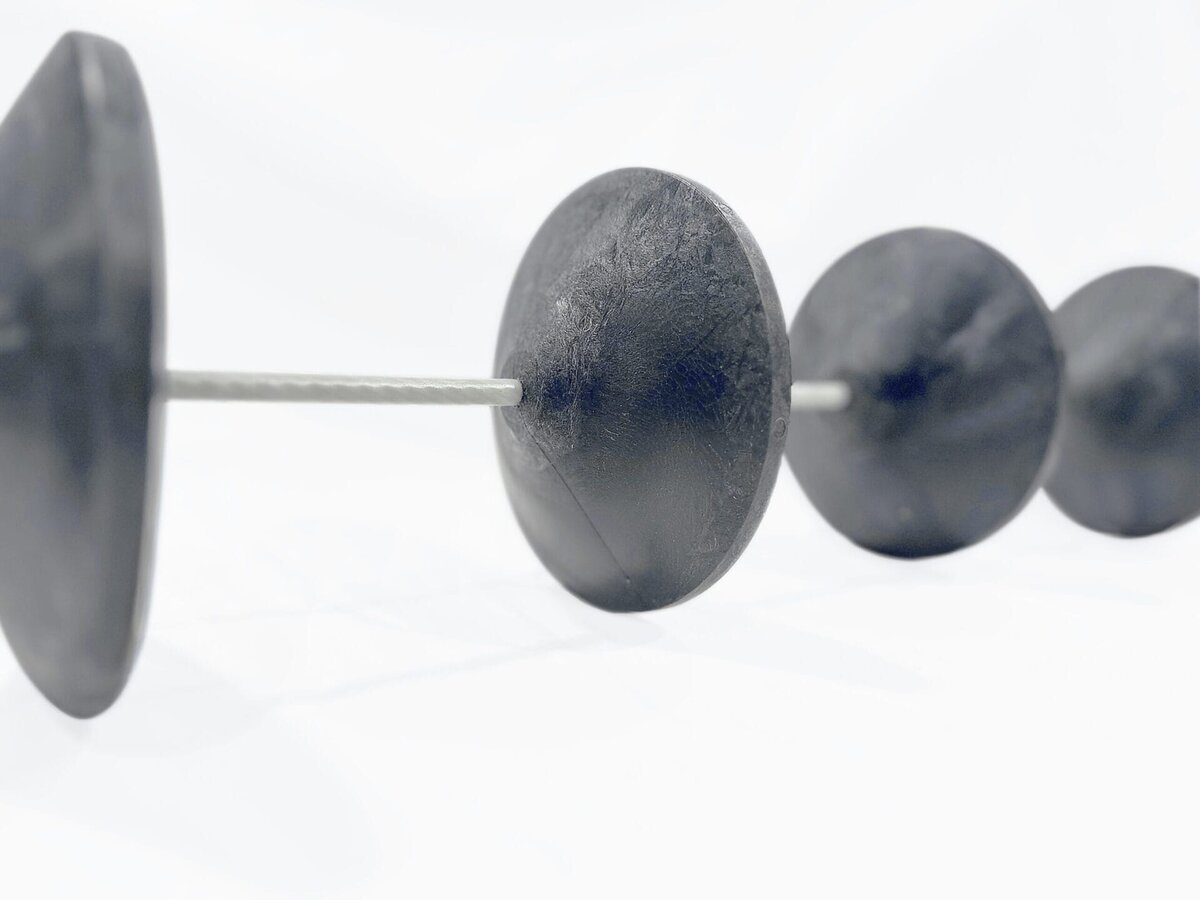

The metal-detectable cable assemblies feature metal-detectable additives in the coating and discs, ensuring that standard metal detectors in processing plants can quickly identify potential contaminants. This solution prevents potential contamination of food products, which is crucial for maintaining the highest quality standards and consumer safety.

“Our new metal-detectable cable assemblies represent a significant step forward in addressing some of the most critical concerns of our customers,” said John Adair, Director of Engineering at Cablevey Conveyors. “Major players in the food processing industry have expressed a clear need for increased safety measures and our new product directly addresses these concerns by providing an additional layer of safety and security.”

The assemblies incorporate a proprietary blend of metal-detectable materials designed to ensure that in the unlikely event of any fragments of the assemblies coming loose during operation, they are detectable by conventional metal detection systems used in food manufacturing. This advancement is particularly relevant for industries where even the smallest contaminants can compromise product integrity and safety, such as in coffee, snacks and various powdered food products.

“We have conducted extensive testing to ensure the reliability and effectiveness of our metal-detectable cable assemblies,” added Adair. “By sending samples of the assemblies to our customers, we have ensured compatibility with their existing metal detection systems. This rigorous approach guarantees that our product meets the highest safety standards and provides the assurance that food processors need to avoid costly product recalls.”

In addition to its detectable properties, the new cable assemblies offer robust performance and durability. It is designed to integrate seamlessly with existing systems, allowing for straightforward retrofitting and inclusion in new installations. This flexibility ensures that manufacturers can upgrade their safety protocols without extensive system overhauls. The metal-detectable cable assemblies are available now to order.

Screenshot

“Cablevey has been dedicated to providing high-quality solutions for material handling needs for over half a century. The launch of these new cable assemblies demonstrates an ongoing commitment to advancing industry standards and improving operational efficiency for its customers,” concluded Adair.

For further information about Cablevey Conveyors and its new metal-detectable cable assemblies, visit https://hubs.ly/Q02J_Rxc0.