To streamline production administration and increase business efficiency, Formagrind Ltd, an experienced subcontract precision engineering company based in Neath, has made a strategic investment in PSL Datatrack production control software. This move has proven pivotal, resulting in “huge efficiency savings for all administrative processes,” according to Barry Herdman, Operations Manager.

Established in 1983, Formagrind has earned a reputation for delivering quality components and tooling to many industries including Aerospace, Defence, Semiconductor, Medical and Automotive. With ISO 9001 certification and a team of 28 dedicated employees, the company’s commitment to excellence is clear.

Formagrind offers a wide range of precision machining techniques including Milling, Turning, Surface & Cylindrical Grinding, EDM Wire & Spark Erosion and Mechanical Assembly. The business ensures precise and efficient processes via an impressive array of machinery: 14 CNC milling machines, 3 CNC turning machines, 3 EDM wire erosion machines, 3 cylindrical grinders, 3 surface grinders, 2 EDM fast hole machines and an EDM spark erosion machine.

Additionally, CAD comparison software, advanced inspection equipment and shot blasting technology are utilised to uphold Formagrind’s commitment to delivering high-class components to its established customer base.

The decision to invest in production control software stemmed from Formagrind’s desire to overcome challenges posed by its existing system. “This had been in place for 20 years. Ordering and receiving materials was time-consuming as all data had to be typed out each time,” comments Barry.

“Visibility of orders wasn’t clear and handling of Bill Of Materials (BOM) items was inefficient,” Barry continues. These pain points spurred Formagrind to seek a solution, designed for subcontract precision engineers, that could streamline internal processes, manage a growing order book and ultimately enhance efficiency.

Upon discovering UK-based PSL Datatrack, Formagrind was impressed by the comprehensive suite of modules and ease of use demonstrated by the software provider. “It was clear from the initial demonstration that PSL Datatrack was the answer. It ticked all the boxes in terms of what we were looking for – a system that could support us and ultimately benefit our customers,” recalls Barry. The tailored sales process and outstanding communication from PSL Datatrack further cemented the decision to invest.

PSL Datatrack worked closely with Formagrind to install the software and provide thorough training to key personnel. “We opted for a phased implementation after setting a ‘go-live’ date, and this has been seamless. Training was excellent and we can’t thank PSL Datatrack enough for the first-class support they offered during this process. It was very well-structured and conducted in a way that made learning the system very easy,” explains Barry.

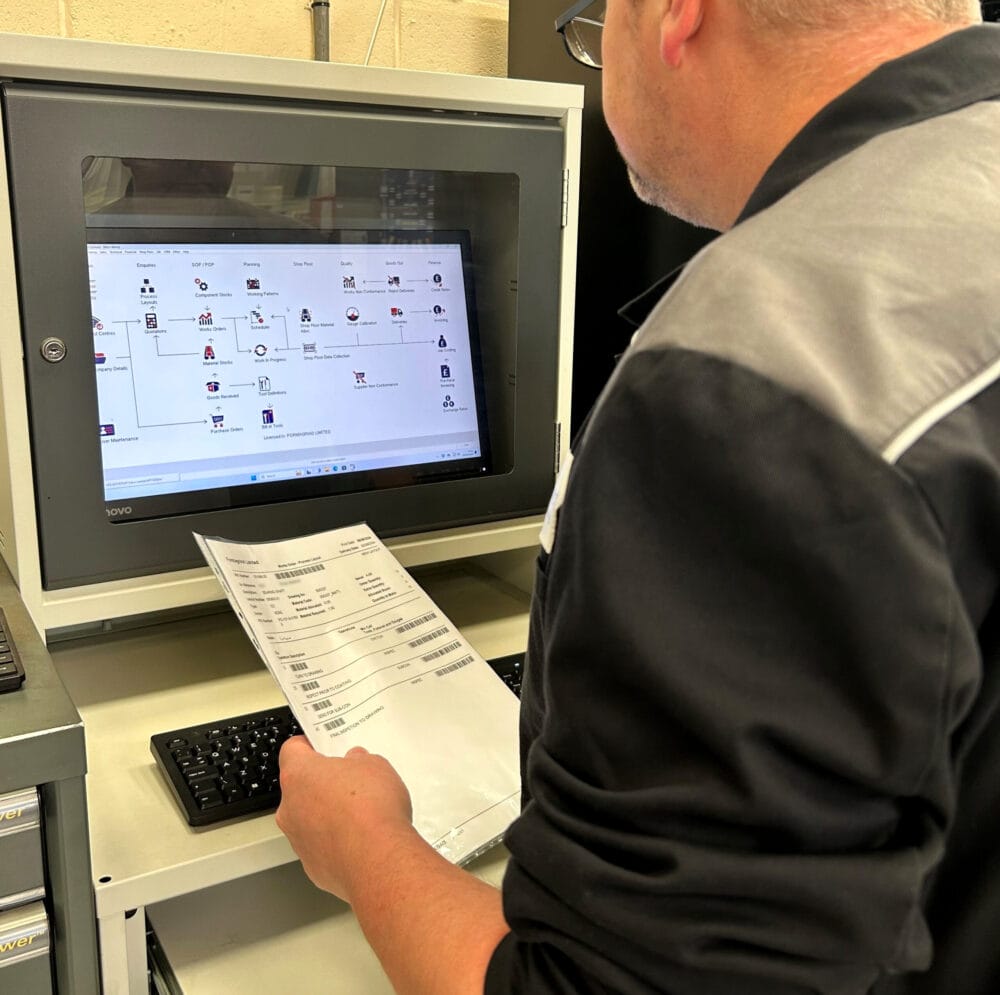

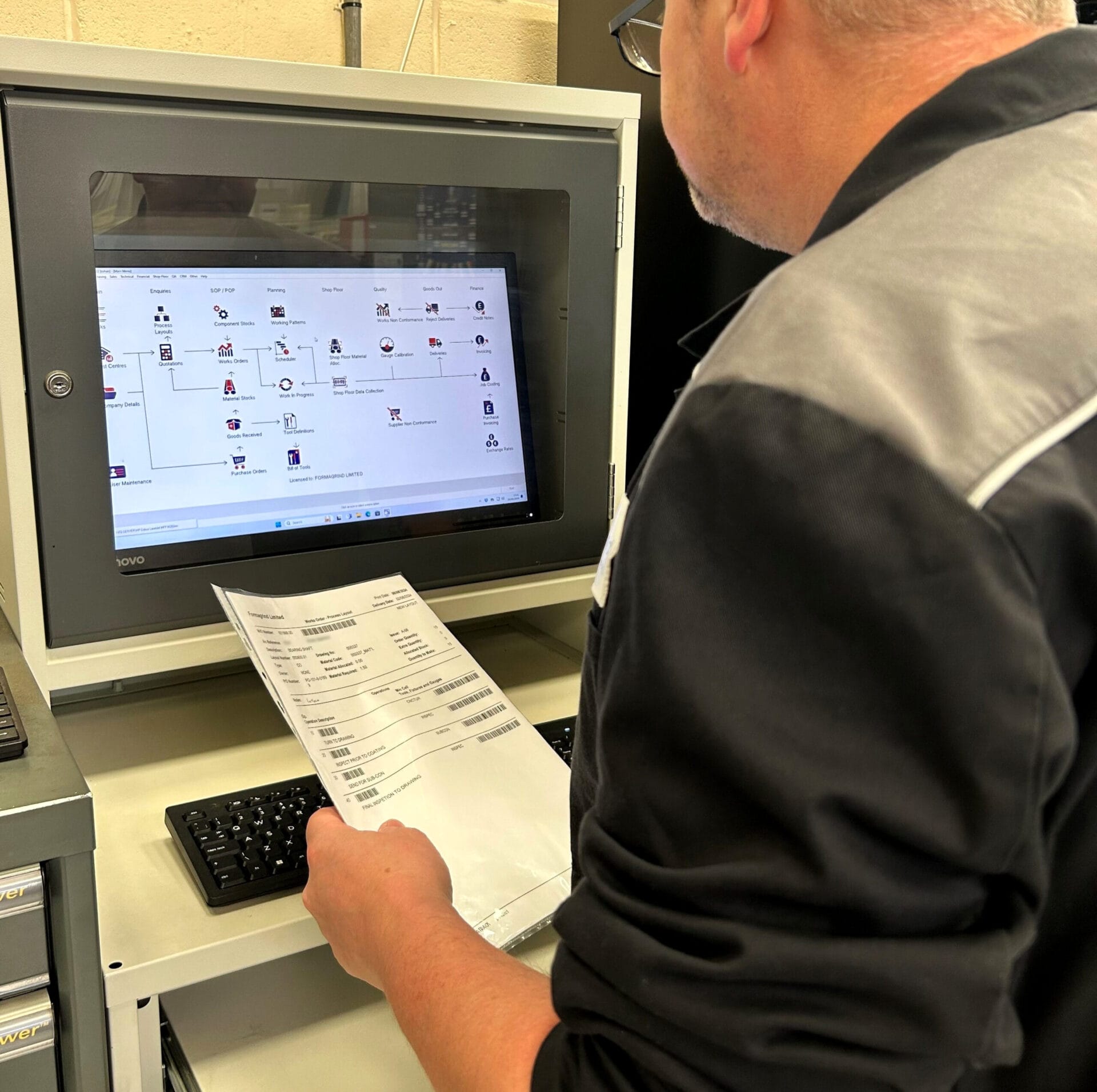

Formagrind has experienced a multitude of benefits since implementing PSL Datatrack. Initially it was management and goods in/out personnel that utilised the system, but the business has recently purchased the Shop Floor Data Collection (SFDC) module meaning all employees will be using the software moving forward.

Administrative processes have been streamlined, enabling huge efficiency savings. Customer orders are now loaded and work started in production much faster, significantly reducing lead times. The company has also cut down on the amount of paperwork it produces as all information is contained in one central system.

“A recent customer auditor had very positive feedback on PSL Datatrack, particularly the documentation and information it is able to produce quickly, which made the audit process a lot smoother,” says Barry.

One of the most significant improvements has been observed in the quoting process. “We are now able to quote our customers a lot quicker than previously, particularly when quoting for large packs of work with multiple price-breaks required,” comments Barry. PSL Datatrack’s Quotations module integrates set and cycle times, machine rates, material and tooling requirements and subcontract processes to ensure all costs are considered.

Additionally, Formagrind has seen an upturn in business since installing PSL Datatrack, securing more business from new customers. “The ease of loading works orders, particularly repeat orders for existing components, is particularly beneficial,” Barry continues. The system’s Works Orders module ensures a smooth transition from production to delivery and invoicing.

Formagrind appreciates the functionality of the entire PSL Datatrack system and all staff members have been impressed by how easy the system is to use and navigate. It can be summed up by one employee asking: “Why didn’t we put this system in years ago!”

The company plans to fully integrate SFDC and introduce the Scheduler and Non Conformance modules (Supplier and Works) in due course to further enhance its operations. “PSL Datatrack is already making a huge difference to our day-to-day activities and we look forward to unlocking more modules in the future,” says Barry.

Formagrind’s success story with PSL Datatrack therefore serves as a testament to the transformative power of production control software. “PSL Datatrack will continue to help us become more efficient and responsive to customer needs while delivering quality products on time, every time to our clients,” concludes Barry.

For more information, visit www.psldatatrack.com or contact PSL Datatrack, Lily Hill House, Lily Hill Road, Bracknell, Berkshire, RG12 2SJ, Tel: +44 (0) 1344 827312, Email: sales@psldatatrack.com