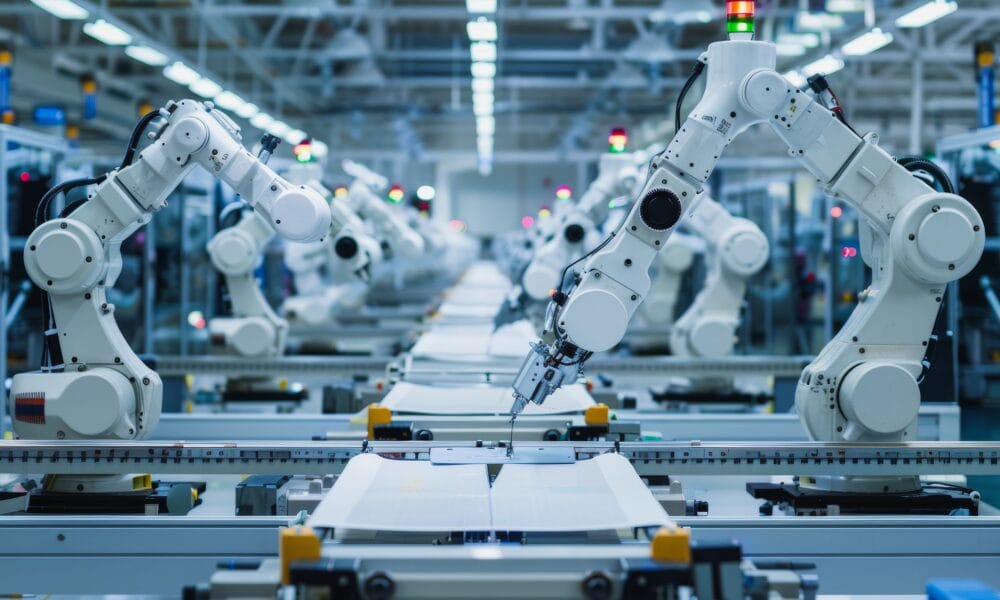

The digitalization of manufacturing is here to stay, and industrial machines must evolve to ensure maximum flexibility and interoperability — both now and in the future. The Module Type Package (MTP) standard enables machine OEMs to meet this goal while gaining a competitive edge in a highly saturated market. Here, Thomas Feßl, Business Development Manager at COPA-DATA, explains how MTP holds the key to future-proof industrial machines for ever smarter factories.

Shorter innovation cycles, smaller product batches and more frequent changeovers are becoming the norm across many industries. In the pharmaceutical sector, this trend is driven by the need to deliver more targeted and personalized medical treatments. In sectors like food and beverage and the automotive industry, companies renew their product lines more frequently to meet changing customer expectations and stay competitive.

Every time a new product or spin-off hits the production line, the manufacturing process evolves. This is where a modular “plug & produce” approach centered on interoperability between hardware and software can help.

MTP: the key to standardization and interoperability

The MTP standard, developed by the User Association of Automation Technology in Process Industries (NAMUR), addresses the demand for greater flexibility in industrial production. The standard promotes maximum interoperability between machines and devices, irrespective of the vendor.

Currently, the release of version 2 of VDI/VDE/NAMUR 2658 with significant improvements and extensions is imminent. Since MTP is applicable to multiple industries beyond process engineering, the Profibus User Organization (PNO) has taken over the responsibility for future updates of the standard. Recently, initial steps have been taken to integrate MTP into IEC 63280 to expand the application of MTP beyond the process industry.

MTP-compliant machines can be integrated seamlessly into production lines and evolve according to changing requirements. Thanks to this modular setup, all work steps are saved in completed modules that users can easily combine into new applications and processes in just a few clicks — with no programming knowledge needed. These modules can then be transferred from R&D to the production line, without requiring any additional reconfigurations.

A future-proof standard

The manufacturing world is evolving rapidly, driven by seemingly unstoppable digitalization. A recent Deloitte analysis found that nearly half of manufacturers are adopting IoT sensors, devices and systems, with more than seven in ten having already integrated data analytics and cloud computing into their processes. In addition, 92 per cent of manufacturers have started experimenting with the industrial metaverse. This unprecedented pace of change requires future-proof machines that can adapt to new digital technologies and processes.

Machine builders who embrace an MTP approach ensure that their products are compatible with the latest technologies. In zenon, modular automation is realized through the use of the zenon Orchestration Studio. This enables users to create a complete control system by orchestrating modular packages in the form of MTP files. The process begins with the import of MTP files into the zenon Orchestration Studio. After that, the MTP files are converted into Smart Object Templates in the higher-level Process Orchestration Layer (zenon POL). These templates function as universal building blocks that can be seamlessly integrated into existing processes. In zenon, they are treated similarly to native objects, allowing for easy handling and integration into automation solutions.

MTP offers significant advantages for operations, particularly in the context of utilizing existing “Brownfield” facilities. By enabling the integration and modernization of existing machinery without the need for complete overhauls, MTP allows for the continued use of current assets while bringing them up to modern standards. This not only leads to cost savings and reduced downtime but also contributes to sustainability by reducing waste associated with the disposal of old machinery.

By supporting both the efficient use of existing resources and the reduction of product waste, MTP plays a crucial role in helping organizations meet their sustainability targets, making it an essential component of modern manufacturing and production strategies.

Giving machine builders a competitive edge

Gaining competitiveness is a priority for many machine builders. An MTP approach can help them gain a competitive advantage in two ways.

Firstly, machine builders can apply this concept to their production lines, becoming more agile in adapting their products to changing market needs and new technological developments. DECHEMA e.V. estimates that embracing MTP reduces manufacturing costs by up to 40 per cent* by swiftly adapting production capacity to actual market demand. This approach also shortens the time to market by up to 50 per cent* thanks to prefabricated modules that engineers can easily transition from product development to production.

The ability to supply MTP-ready machines, gives machine builders another core competitive advantage: positioning their products as genuinely modular, interoperable and future-proof.

Better communication, better collaboration

Another core benefit of the MTP standard is that it allows more effective communication and collaboration between machine builders, system integrators and end users. This outcome translates into reduced faults, better products and increased customer satisfaction.

Using the same standard also reduces misunderstandings and errors during machine commissioning. The ability to examine all components at a glance makes it easy to pinpoint and fix problems early on, preventing costly downtime during production.

Simpler system integration and maintenance

In essence, standardization of machine modules with MTP simplifies system integration, as all components speak the same language. Changes or extensions can be implemented more efficiently, as standardized MTP files provide a clear and consistent description of machine functions. Engineers can update projects and activate changes without shutting down the machine. This way, machines can adapt to new information and keep the system updated while preventing costly equipment shutdown.

Machines are, and will continue to be, the building blocks of modern smart factories. Giving these machines enhanced and lasting connectivity and interoperability is a key step to a successful digital and sustainable future.

To learn more about going modular in your operation, visit the COPA-DATA website here.