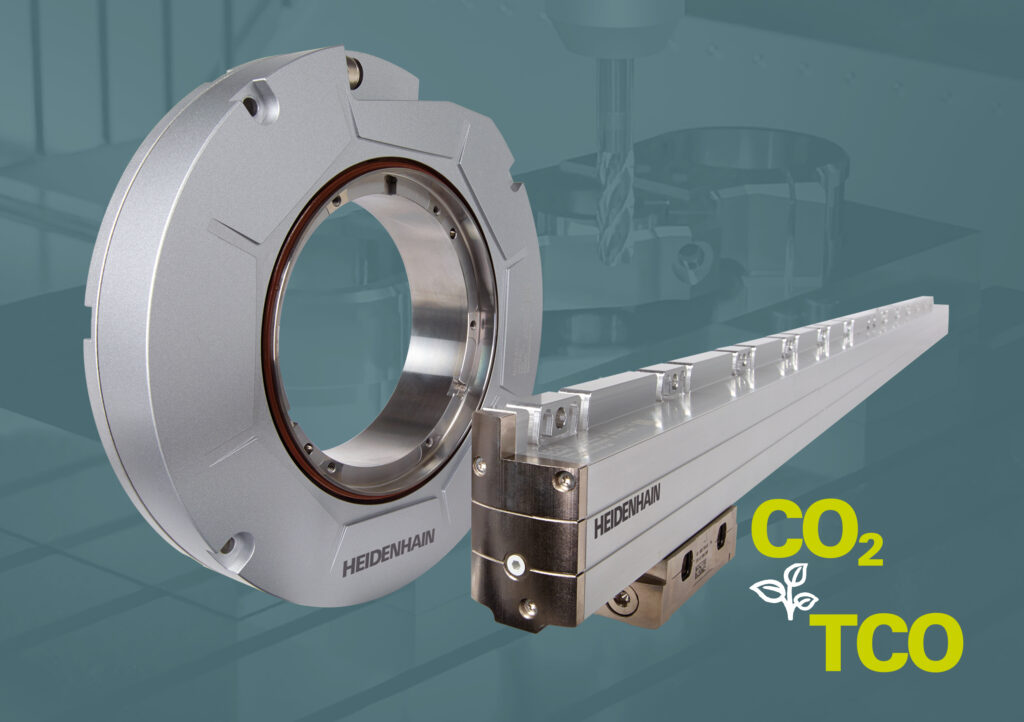

Sealed HEIDENHAIN encoders with innovative True Image technology ensure unimpeded scale readings regardless of condensation and other liquid contamination in a machine tool. Series 6 LC linear encoders from HEIDENHAIN and series 1 RCN angle encoders can reliably deliver highly accurate position values, in many cases even without any purge air. That lowers the system costs and reduces the encoders’ carbon footprint by up to 99%.

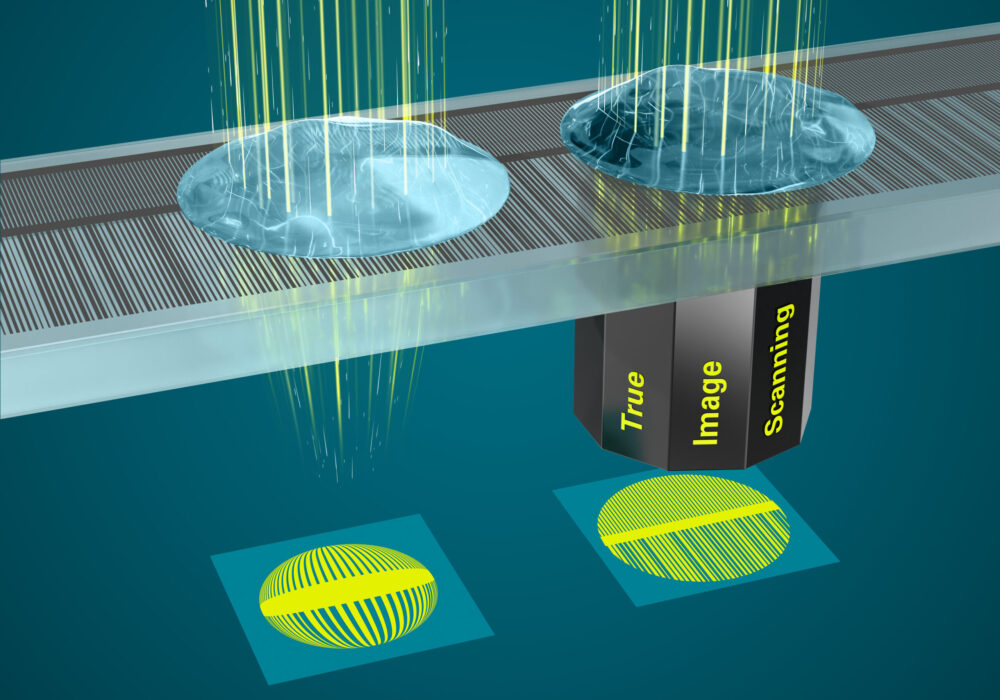

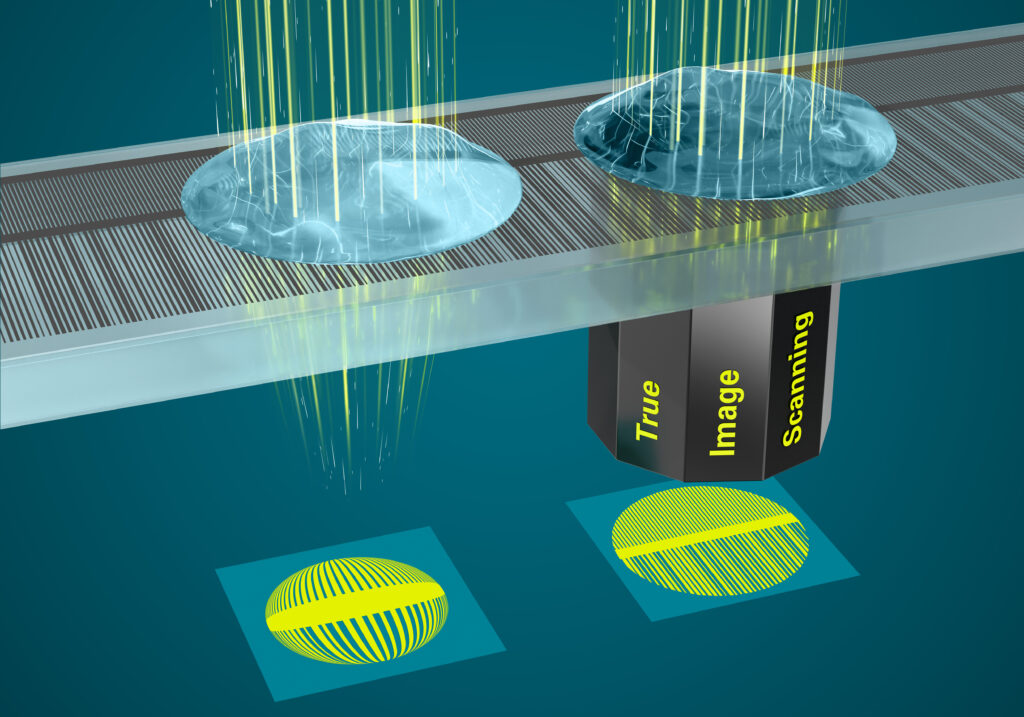

The use of coolant during machining leads to condensation and liquid contamination in the machine tool. But the sealed series 6 LC linear encoders and the series 1 RCN angle encoders with integral bearing from HEIDENHAIN deliver clear scale readings despite contamination. The innovative True Image technology ensures this. A special light guiding element fully eliminates the typical optical distortion of a graduation that occurs when, for example, there are droplets on the scale. An unobstructed image of the graduation lines arrives at the scanning head even if there is liquid contamination.

- The LC and RCN sealed encoders from HEIDENHAIN with True Image technology simplify a machine tool’s purge-air needs, which can reduce the carbon footprint by up to 99%.

- Reduce your carbon footprint and TCO: Equipped with True Image technology, HEIDENHAIN encoders deliver high-accuracy position feedback without purge air.

Series 6 LC linear encoders from HEIDENHAIN and series 1 RCN angle encoders can reliably deliver highly accurate position values, in many cases even without any purge air. The purge air system of a machine can be greatly simplified, the carbon footprint of the encoders reduced by up to 99%, and the overall system costs lowered significantly. The contamination-resistant optical components permanently improve a machine tool’s productivity, and also increase its availability despite not using any purge air. And by reducing the number of components in the purge air system, the True Image technology also makes quicker installation of the encoders possible.

| For more information, visit:

live.heidenhain.com

|

Contact person:

Philip Lodge

|