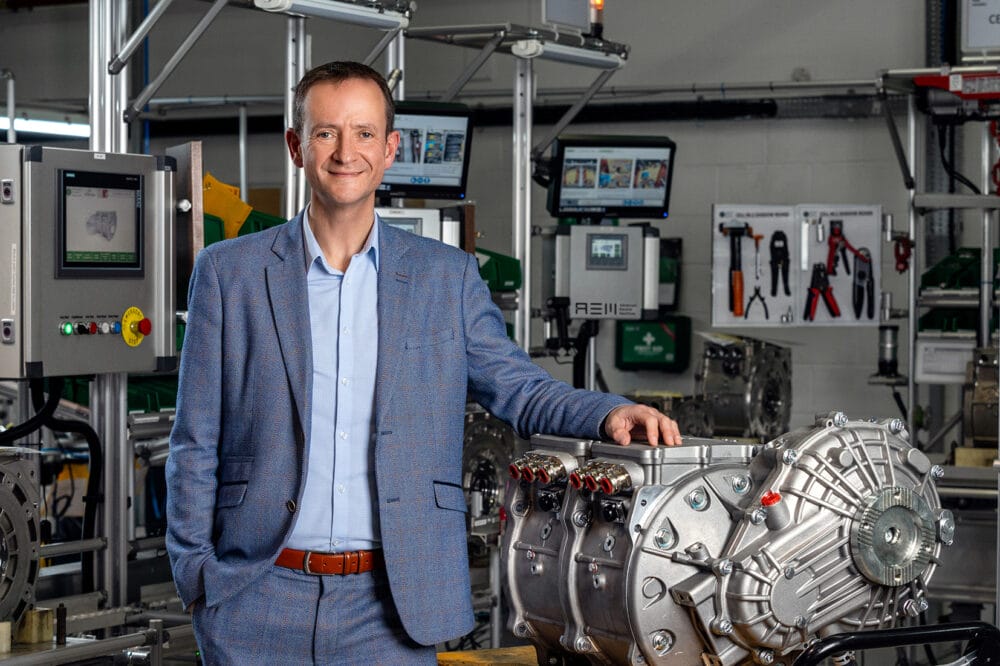

A specialist designer and manufacturer of sustainable electric motors and powertrain systems has tapped into a new skills pilot to help it achieve ambitious expansion plans – fuelled by a recent £23m raise.

Washington-based Advanced Electric Machines (AEM), which was spun-out of Newcastle University by James Widmer and Andrew Steven, is one of the first companies to take part in the Electrification Skills Training Programme – an intensive bootcamp that businesses and individuals can sign up to through the ERS Hub.

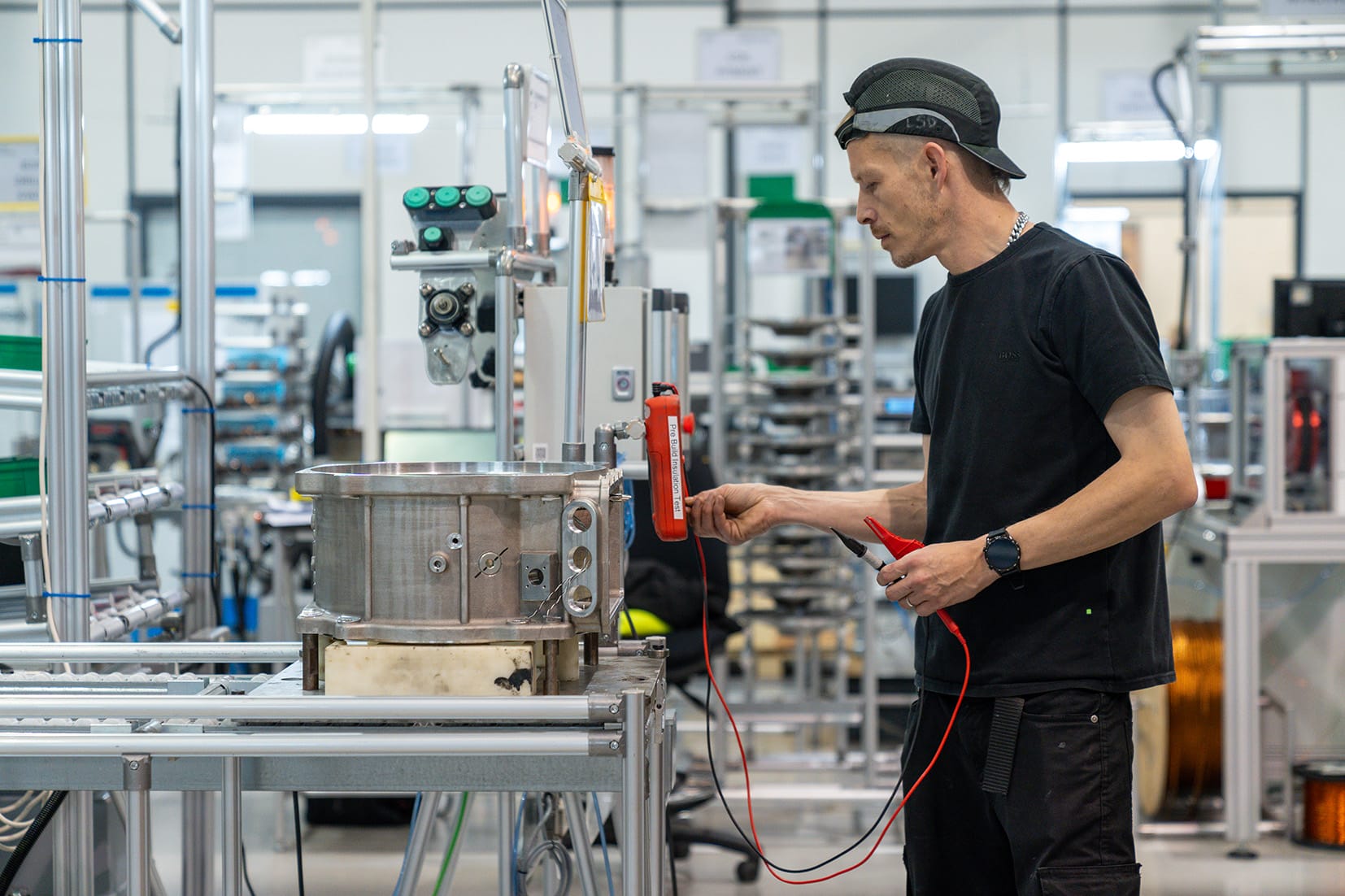

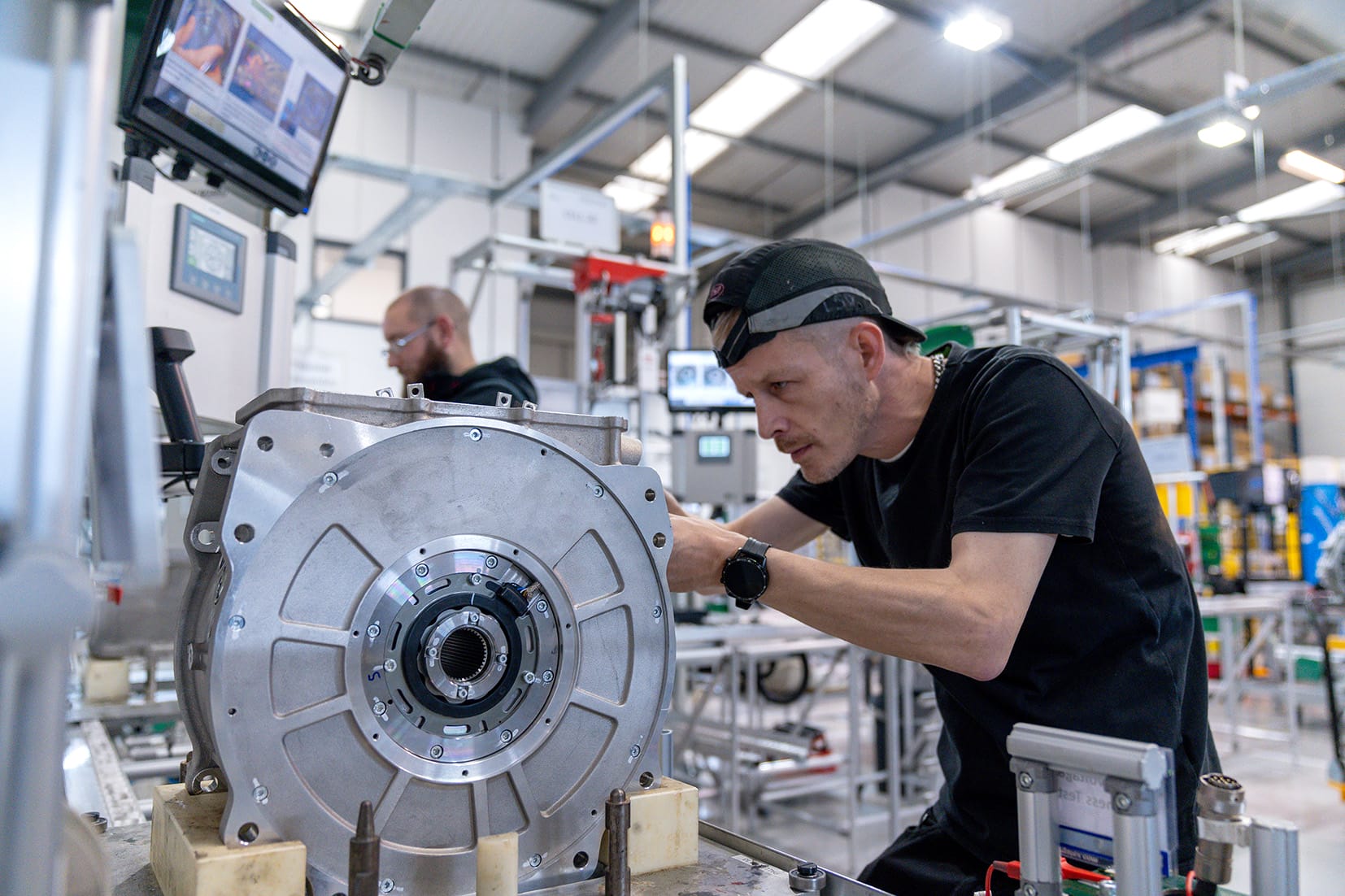

The company put 25 of its employees through the three-day course, touching almost every part of its business and involving people in production, procurement, mechanical engineering, electrical and power electronics engineering.

Feedback has been extremely positive, especially around the fact the content has been pitched at different levels of Power Electronics, Machines and Drives (PEMD) expertise, starting at fundamentals and then moving up to intermediate and through to advanced.

This covered numerous key topics including electronic circuits, high voltage, health and safety, electrical machines, the typology of MOSFETs and IGBTs, inverters, e-motor drives, DC motors and asynchronous/synchronous motors.

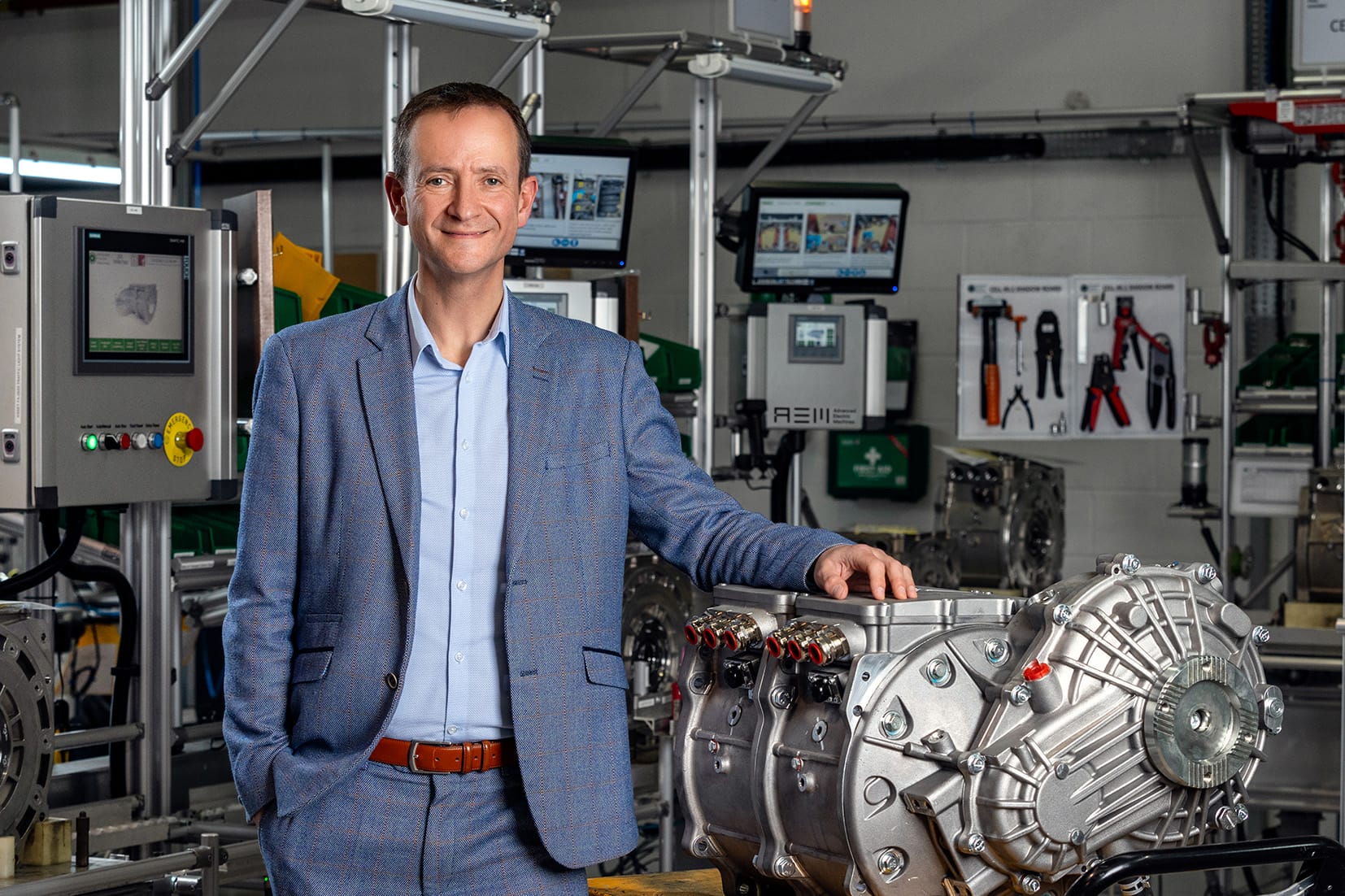

James Widmer, Co-Founder of AEM, said: “We are in an exciting position, having recently raised £23m to support our ongoing expansion and meet demand for our electric powertrain solutions that are free from rare earth materials.

“Part of this funding will help us recruit many more people over the coming years and this will mean upskilling our own team members, as well as bringing engineers in from other sectors. That’s why we wanted to get involved with helping shape and test drive this new Electrification Skills Training Programme.”

He continued: “This is a topic that is much bigger than AEM. Jobs are being created faster than our sector can fill them. A lot of the skills companies need are also still being defined and that is another challenge.

“I firmly believe this pilot is an important first building block in addressing some of these issues and can be applied to apprentices, graduates or existing members of staff that need a ‘refresher’ or those keen to advance their knowledge.”

AEM designs and manufactures electric powertrain technologies that deliver industry-leading performance, range and efficiency – all without the need to use environmentally damaging rare earth magnetic materials. Its motors are simple to recycle and more sustainable to produce.

The company’s pioneering products are used across the world in commercial vehicles, passenger cars, off-highway vehicles, trains and a host of industrial applications.

James, who is an electrical engineer by trade, went on to add: “We’re up to about 80 people in the business now. Some are experts in PEMD, but most of them have been recruited from different engineering disciplines, including mechanical engineering, oil and gas and aerospace.

“These valuable team members bring core manufacturing knowledge, but some will need to develop their understanding of how electric motors and drives work. That’s why we had supply chain managers, production operatives and purchasers all taking part on the Electrification Skills Training Programme.”

He continued: “Time is precious. Bringing the sessions to a local facility is a big plus for businesses. It means we can release our staff to take part in some or all the training and this has allowed us to maximise the number of team members who could take part.”

The Electrification Skills Training Programme – developed in close partnership with Coventry University and the North Warwickshire and South Leicestershire College (NWSL) – will be rolled-out in full over the next few months.

This follows on from the successful completion of the development stage, which was funded by the Innovate UK and in partnership with FEV, DSD, ZF, GE, AEM and FluxSys.

The project brought together a diverse collaboration of organisations, industry and training providers – all with a track record in Power Electronics, Machines and Drives and delivering large-scale skills interventions.

A team of five Coventry University PEMD experts, Lu Wang, Soroush Faramehr, Tony Smith, Chris Atanasov and Petar Igic, delivered the AEM bootcamp and valuable feedback from course participants was used to ensure future content is tailored to industry needs.

Petar Igic, Academic Director of the ERS Hub, continued: “These bootcamps have been collaboratively led by extensive research with employers and field experts. The AEM delivery allowed us to further tweak the content and delivery methodology, giving future clients even greater value and an engaging experience.

“The overarching reaction from individuals taking part was extremely positive, so we’re confident we’ve got a format that is adaptable and versatile to suit specific requirements and now need more employers to come forward to take advantage.”

James, who also chairs the ERS HUB Advisory Group, concluded: “The electrification sector is in an exciting place, and we must think about how we can grow skills quickly. That’s why I’d love to explore how we could potentially licence the Electrification Skills Training Programme so other experts can deliver it across the country.”

For further information on the Electrification Skills Training Programme, please visit www.ershub.co.uk. More details on AEM, please go to www.advancedelectricmachines.com

To learn more about the course delivery team visit – https://shorturl.at/wourD