As the demand for renewable energy solutions continues to grow, precision manufacturing processes like photo-chemical etching (PCE) are playing a pivotal role in advancing the performance and efficiency of technologies such as solar and fuel cells. micrometal and its subsidiaries, leaders in PCE, is at the forefront of this innovation, delivering high-precision components that are essential for optimising the efficiency and reliability of renewable energy systems.

“Renewable energy technologies, particularly solar and fuel cells, require components that not only meet stringent technical specifications but are also produced with minimal material waste and high repeatability,” explains Jochen Kern, Head of Sales & Marketing at micrometal. “Our expertise in PCE allows us to create intricate metal parts with extremely fine tolerances, which are critical for enhancing the performance of these energy systems.”

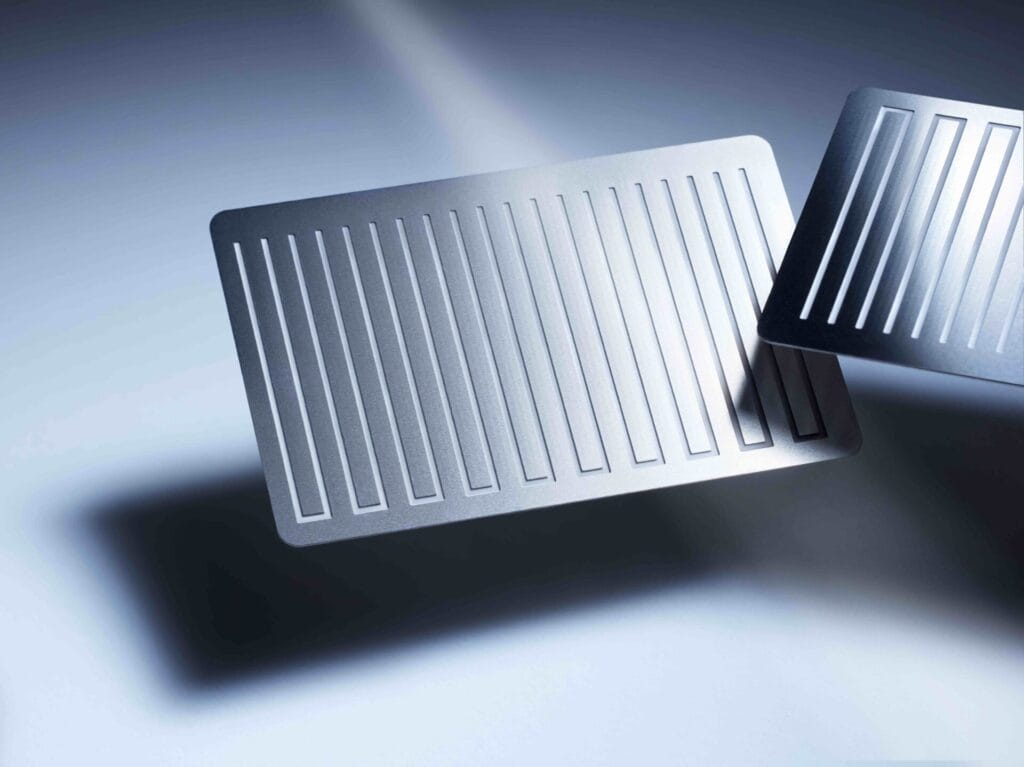

PCE is a versatile and precise manufacturing process that enables the production of complex, high-quality metal components without the need for expensive tooling or mechanical stress on the materials. The technique is particularly beneficial for the renewable energy sector, where components like metal contacts, current collectors, and flow field plates must be manufactured to exacting standards to ensure optimal electrical conductivity, minimal resistance, and efficient heat dissipation.

For solar cells, micrometal’s etched metal components help maximise the surface area of contacts, which is crucial for improving the efficiency of electricity generation. By minimising shadowing and optimising the metal’s contact area with the photovoltaic material, the etching process ensures that more sunlight is converted into usable energy. This results in higher overall efficiency and better performance of solar panels.

In the case of fuel cells, precision-etched components such as flow field plates are vital for controlling the distribution of gases within the cell. The high precision offered by micrometal’s etching processes ensures that these plates can be manufactured with intricate channel designs that facilitate efficient gas flow, reduce pressure drops, and enhance the overall performance and durability of the fuel cells. The ability to produce these components with such precision directly translates to improved energy output and reduced material costs.

“By leveraging our PCE capabilities, we are not only contributing to the advancement of renewable energy technologies but also supporting a more sustainable future,” adds Kern. “Our focus is on delivering innovative solutions that help our customers achieve higher efficiency and lower costs in their renewable energy applications.”

As the renewable energy sector continues to evolve, the role of precision manufacturing technologies like PCE will only become more critical. micrometal and its subsidiaries remain committed to supporting this growth by providing the high-quality, precision-engineered components that are essential for the next generation of sustainable energy solutions.