~ EMS to showcase latest drive system innovations and custom design expertise ~

Drive system supplier Electro Mechanical Systems (EMS), the UK and Ireland’s exclusive distributor of FAULHABER drive systems, will attend this year’s edition of Machine Building Live. At the show, EMS will showcase its extensive capabilities in custom drive system design and the latest developments in advanced drive systems to an audience of machine builders, systems integrators and OEMs.

Bringing together an array of machine building technical experts under one roof, the one-day event serves as a key gathering for professionals involved in machine building, systems integration and industrial automation. EMS aims to demonstrate how its drive solutions can contribute to more efficient, reliable and compact machine designs, aligning with the event’s focus of optimising performance.

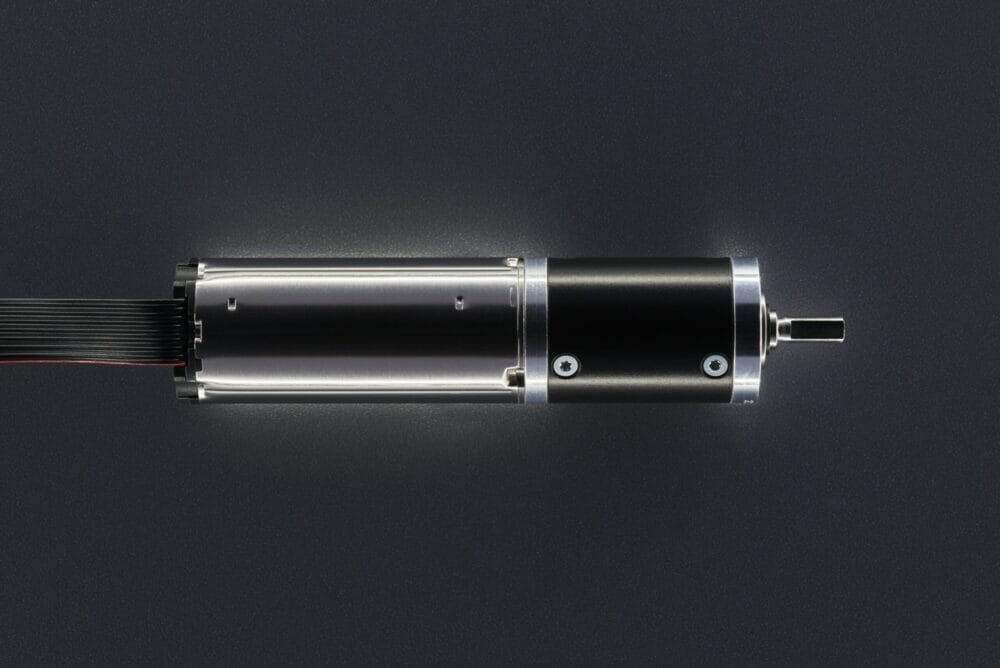

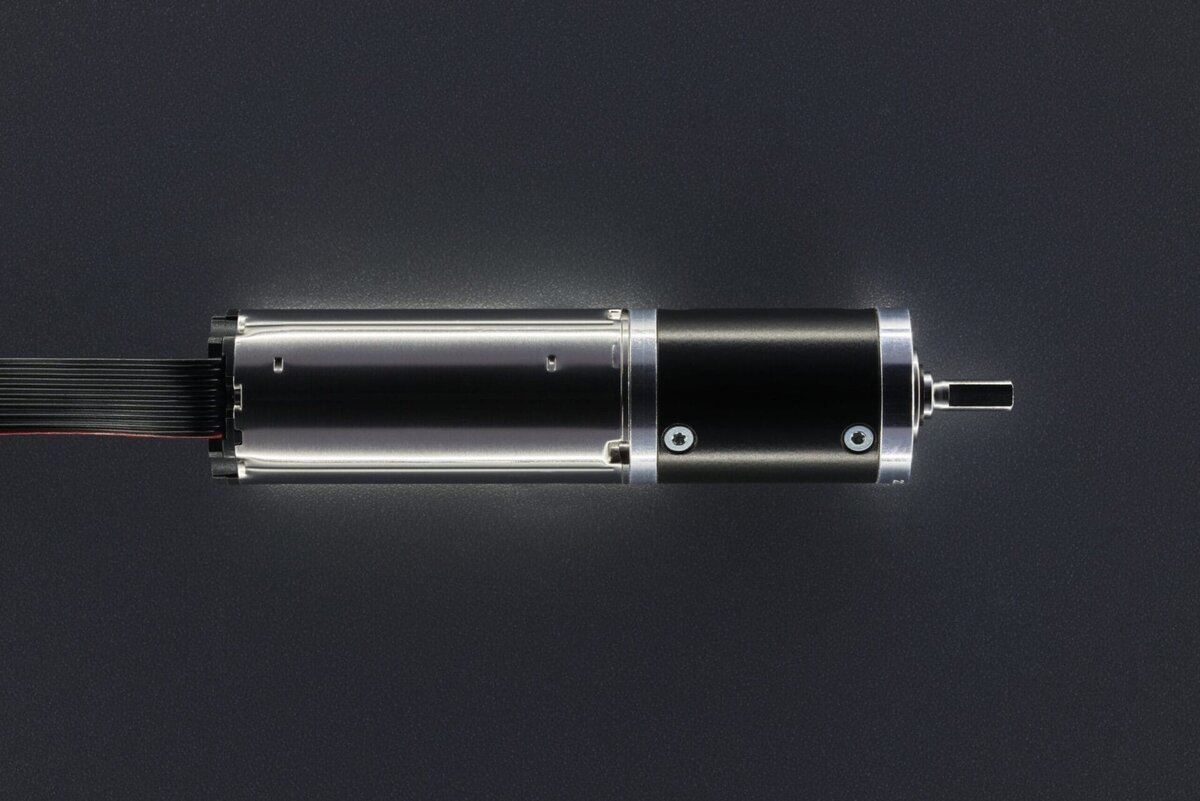

Among the key products EMS will present is the FAULHABER BX4 integrated motion controller (IMC), which was launched earlier in 2024. The BX4 IMC adds just 18 millimetres to the length of the drive system and features a complete servo controller and a 12-bit encoder, providing precise positioning and control for even the most demanding applications.

Also on display will be the FAULHABER IEP3 incremental encoder, offering highly accurate positioning data from a remarkably compact eight millimetre package. With resolutions of up to 10,000 lines per revolution, the IEP3 is ideal for applications requiring precise measurement in limited spaces. The encoder’s customer-specific resolutions are freely programmable, allowing machine builders to tailor it to their specific needs.

“Machine Building Live presents a unique opportunity for EMS to engage directly with machine builders and systems integrators,” explained Dave Walsha, sales manager at EMS. “As industries demand more functionality within smaller footprints, FAULHABER products, such as the BX4 IMC and IEP3, offer unmatched precision and performance in compact designs. This is particularly crucial in machine building, where space and reliability are at a premium.”

Alongside demonstrating a comprehensive range of drive systems from its partner network, EMS will also be on hand to consult and advise on its own custom design capabilities. With its continuously expanding in-house manufacturing capabilities, EMS creates custom gearboxes for customers with specialised requirements.

“When standard off-the-shelf components fall short of specific application requirements, our custom design process, which considers speed, torque, duty cycle, environmental factors and space constraints, can overcome any limitations,” continued Walsha. “This flexibility and quick turnaround results in a high-quality, bespoke product tailored to enhance machine performance. We’ve recently upgraded our shop floor with several new state-of-the-art machines as a result of increased interest in our custom design offer, and we look forward to discussing this further with Machine Building Live’s attendees.”

Visit EMS at Machine Building Live on 2 October 2024 at stand 137, or find out more about available drive system solutions by getting in touch via the website.