Typically, the anticipated lifetime for transformers with cellulose based solid insulation can be several decades when operating under nominal load and specified ambient temperature conditions. However, transformer aging is affected by a number of factors including design, materials, insulation system contaminants, and operating conditions. The combination of water, oxygen, and acids within the solid insulation speeds up the aging process and degrades cellulose molecules, resulting in diminished mechanical strength and a shorter operational lifespan for the transformer. The challenge for transformer managers is to be able to reliably detect the early indicators of premature ageing so that timely action can be taken.

Under normal operating temperatures and in a water and oxygen-free environment, ageing processes would be almost non-existent. However, the creation of such conditions is not practical or economically viable. It has been reported (1), for example, that if oxygen levels in the oil remain below 2000 ppm, the insulation system ages more than five times slower than in a free-breathing transformer. However, this aging is not limited to just the cellulose; insulation oil also undergoes aging, mainly through oxidation, which forms carboxylic acids that can accelerate paper aging.

Oxygen and moisture challenges

Ambient air is the sole source of oxygen in transformers and the primary source for moisture. Transformers are therefore fitted with preservation systems such as rubber bags or nitrogen blanketing, which create a protective barrier between the insulation oil and the surrounding environment. Modern power transformers are usually fully sealed, and older units are frequently upgraded with sealing systems to prevent the ingress of moisture and oxygen. Air leaks are generally caused by gasket or rubber bag deterioration, particularly when transformers operate at higher loads. The increasing use of sealed designs means that asset managers need to ensure that transformer tanks remain airtight.

The limitations of older monitoring methods

Traditional methods for the detection of air leaks involve the measurement of oxygen and nitrogen in standard DGA oil samples. However, the risk of sample contamination by air has been a major challenge because samples can pick up oxygen as they are handled and transported, resulting in incorrect data interpretation.

In recent decades, technology has been developed for the online measurement of oxygen concentration in oil to confirm air entry. However, this method may not detect slow air leaks when active oxidation processes are simultaneously consuming oxygen. Over six decades have passed since the industry started using dissolved gas analysis, but there is still no recognized standard practice for the interpretation of oxygen concentration, so an experienced DGA specialist is usually required for the interpretation of oxygen measurements.

Some DGA monitors calculate nitrogen levels from integrated oxygen measurements, but these calculations assume constant oxygen/nitrogen ratios in air-saturated oil, making them unsuitable in that respect for sealed transformers.

What really matters for asset maintenance teams?

In order to fully understand the aging process, it is necessary to measure oil quality parameters, such as acidity, and ageing markers like furans or methanol, as well as gas concentrations such as oxygen, carbon dioxide and carbon monoxide. The assessment of solid insulation life expectancy is a complex task that demands a high level of expertise. This is because, in contrast with transformer faults that may develop rapidly, oxidation is a slow process, usually taking years to show significant progress. Therefore, real-time gas monitoring is better suited to the detection of quickly evolving faults, than it is for tracking oxidation.

In reality, decision-makers in transformer maintenance do not need to know precise oxygen or nitrogen concentrations. What they really need to know is whether the insulation system of a sealed transformer is exposed to air, which allows them to make informed decisions on actions such as oil degassing or dry out or sealing system repair.

Total gas pressure (TGP) – a step forward in air leak detection

A simpler way to detect air entry is by measuring the pressure of all dissolved gases. TGP sums up the partial pressures of all the gases, to produce a more useful, easy-to-understand parameter. The key fault gases (carbon monoxide, carbon dioxide, hydrogen, methane, acetylene, ethylene and ethane) represent a tiny fraction of the total pressure, whereas nitrogen and oxygen are dominant. An increase in TGP in a sealed transformer therefore signals an air leak, without the need for specialized expertise.

Degassing of oil during commissioning should ensure that dissolved gas pressure is very low in newly installed sealed transformers. A noticeable increase in pressure therefore indicates a potential problem, and demonstrates the advantage of TGP over oxygen measurement, which may remain relatively unchanged due to oxygen-consuming reactions.

A properly sealed transformer should maintain low gas pressure levels for its entire lifespan – well below atmospheric pressure 1000 hPa (14.5 psia). However, a rise in TGP values is a clear indication of air entry. If the data indicates a recent ingress of air marked by an increase in TGP, maintenance teams can decide whether they need to inspect and repair the sealing system during the next service break, to prevent further deterioration of the insulating paper due to oxygen.

TGP measurement in practice

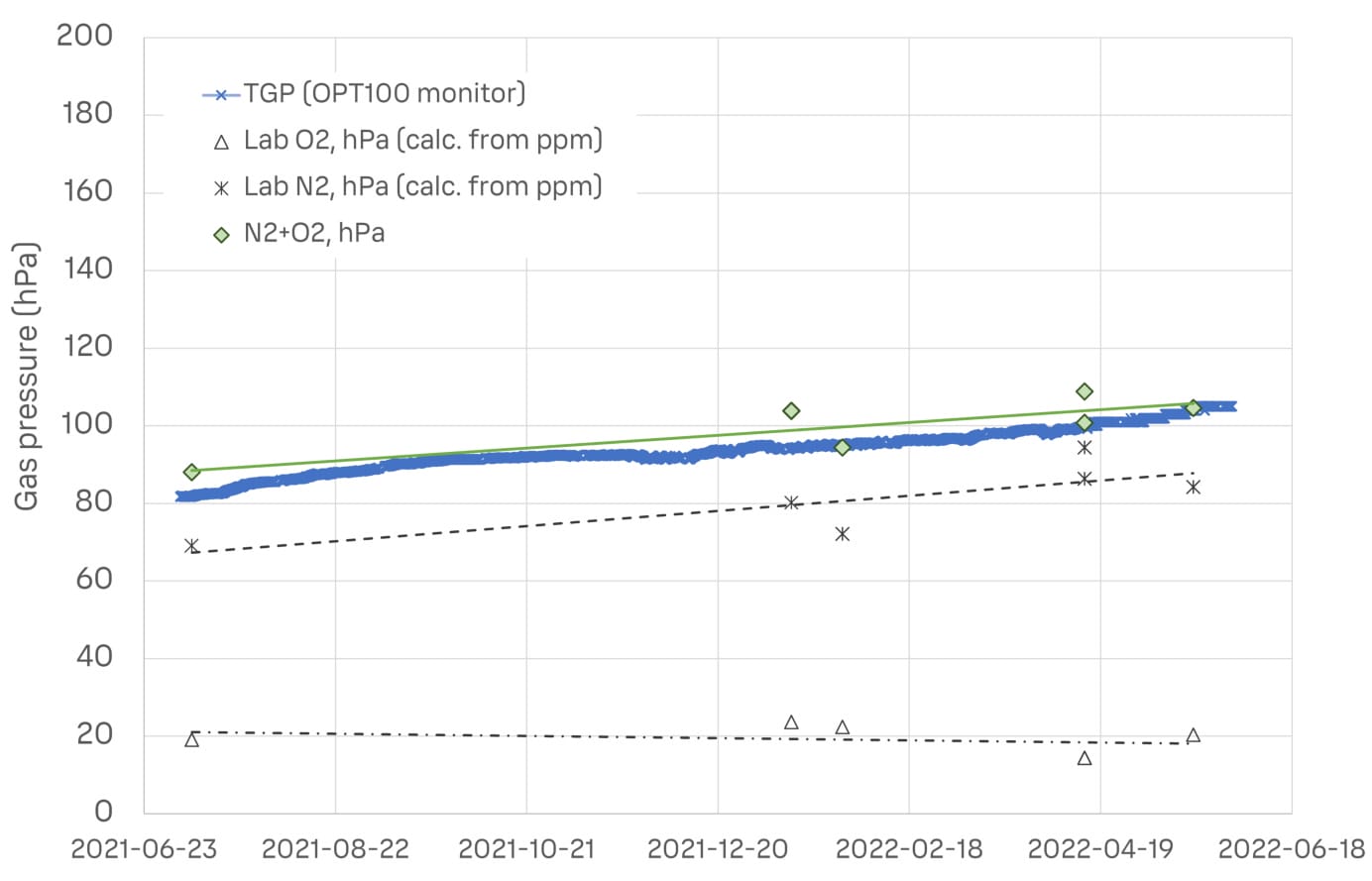

The TGP in operational membrane-sealed transformers usually ranges between 100 to 300 hPa (1.45-4.4 psia). Figure 1 illustrates TGP readings provided by the Vaisala OPT100 online DGA monitor in comparison with calculated partial pressures of oxygen and nitrogen at 50°C, based on gas concentrations determined by a laboratory from standard DGA oil samples with gas chromatography. The data is from a new transmission transformer with membrane sealing, with monitoring initiated a few weeks after commissioning.

Over an 11-month period, TGP increased by 23 hPa (0.33 psi) with a corresponding increase in nitrogen (N2) of 1500 ppm and no detected change in oxygen (O2) levels. The clear increase in nitrogen concentration without a rise in oxygen indicates an active ageing process, which is likely to be consuming the oxygen. This highlights the sensitivity of pressure measurement to even minor levels of air ingress. An additional advantage of TGP measurement is that it is inherently free from air contamination, which is a constant risk when working with oil samples.

Figure 1: Total gas pressure (TGP) and calculated partial pressures of oxygen and nitrogen at 50°C with linear fitting

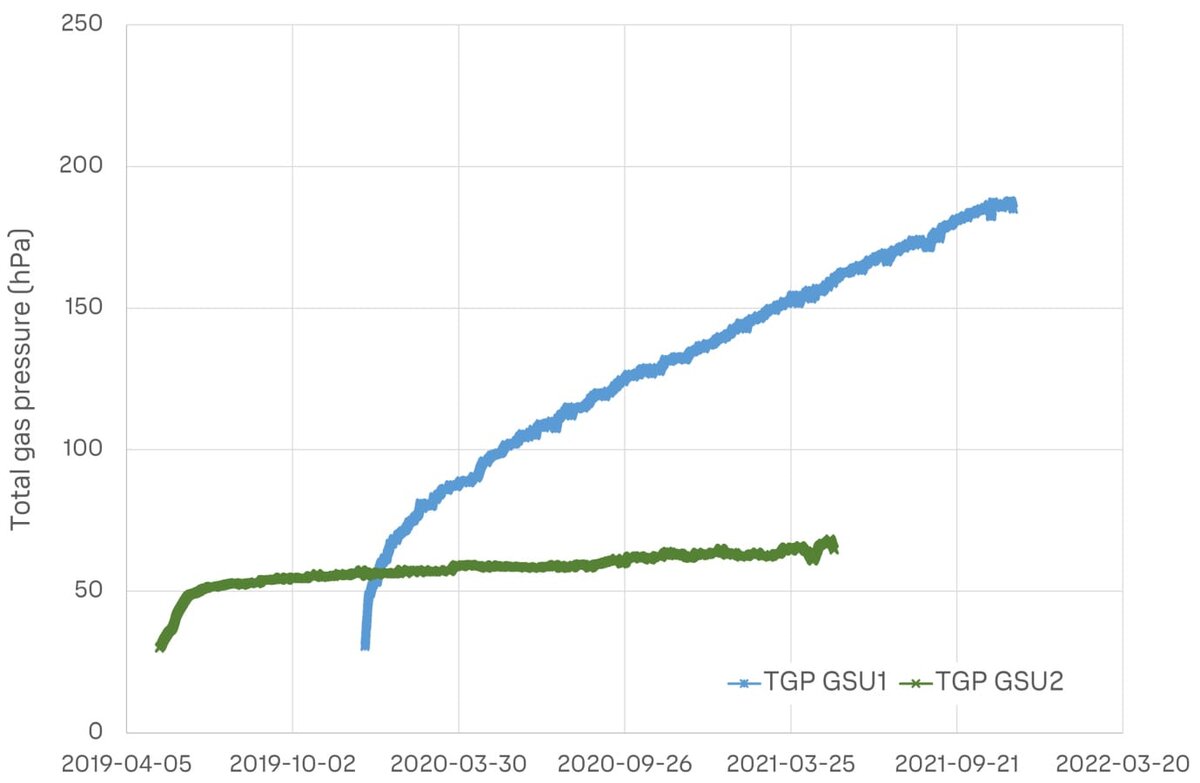

Figure 2 provides real-time TGP readings measured at two sealed generation step-up (GSU) transformers.

Figure 2 TGP data from two new power transformers immediately after commissioning

The GSU1 transformer maintains a consistently low TGP level in its initial two years. The TGP level rises markedly immediately after commissioning due to air from the transportation phase, present in the oil-impregnated paper. However, this gradually moves to the bulk oil, causing a slight increase in TGP, which then stabilizes at a low level. The average annual increase in TGP after stabilization is only 7 hPa (0.1 psi), suggesting that it would take around 130 years to reach equilibrium with atmospheric pressure. The data therefore indicates that GSU1 is well-sealed and does not require any additional investigation or maintenance.

The TGP data for the GSU2 transformer presents a different, more concerning scenario. After degassing, a rapid TGP increase of 30 hPa (0.43 psi) is revealed, due to gas coming from the oil-impregnated paper. However, in contrast with GSU1, the readings do not then stabilize; instead, they continue to rise significantly. Over the next two years, the rate of change is approximately 60 hPa/year (0.87 psi/a), and if this were to continue, it will take just 15 years for the oil to become saturated with air. Clearly, oxygen and possibly moisture are entering the transformer continuously, potentially reducing its lifetime.

With the benefit of the TGP monitoring data, it becomes possible to weigh the expected lifespan of the transformer against the costs of investigating and repairing the leak or implementing mitigation measures. TGP therefore represents the ideal monitoring technology for the reliable protection of transformers.