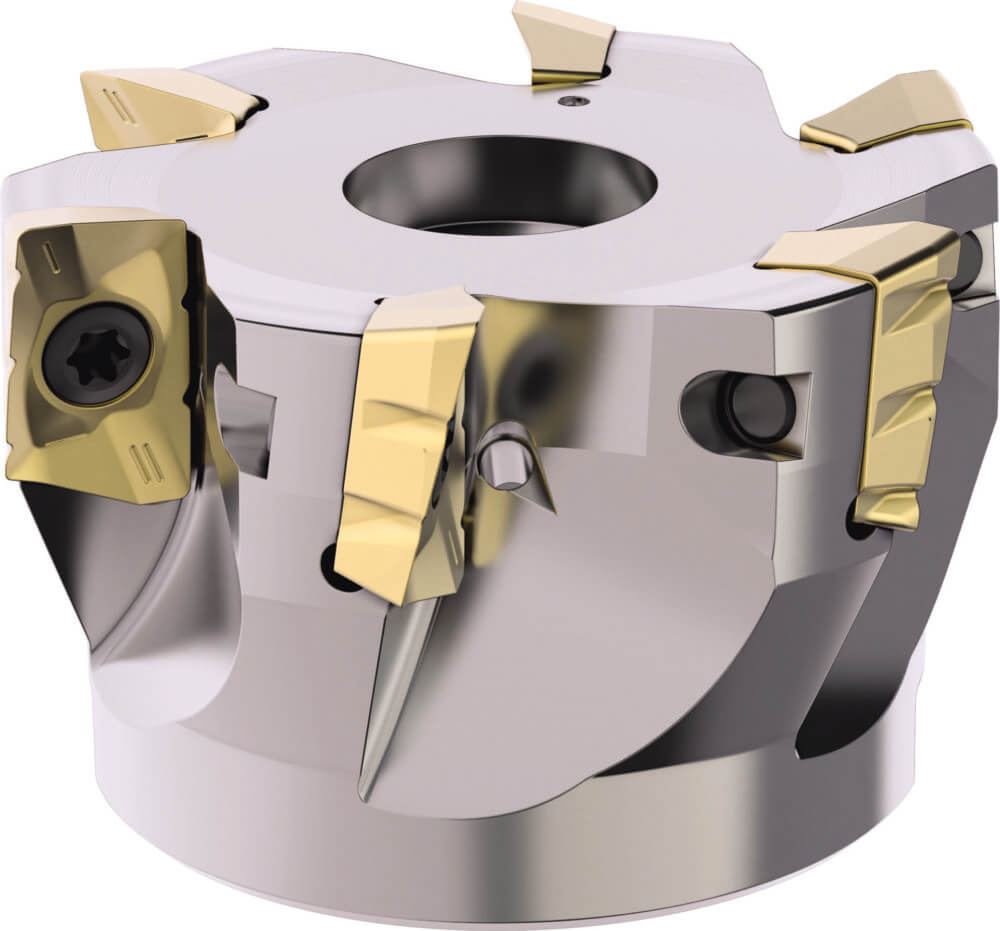

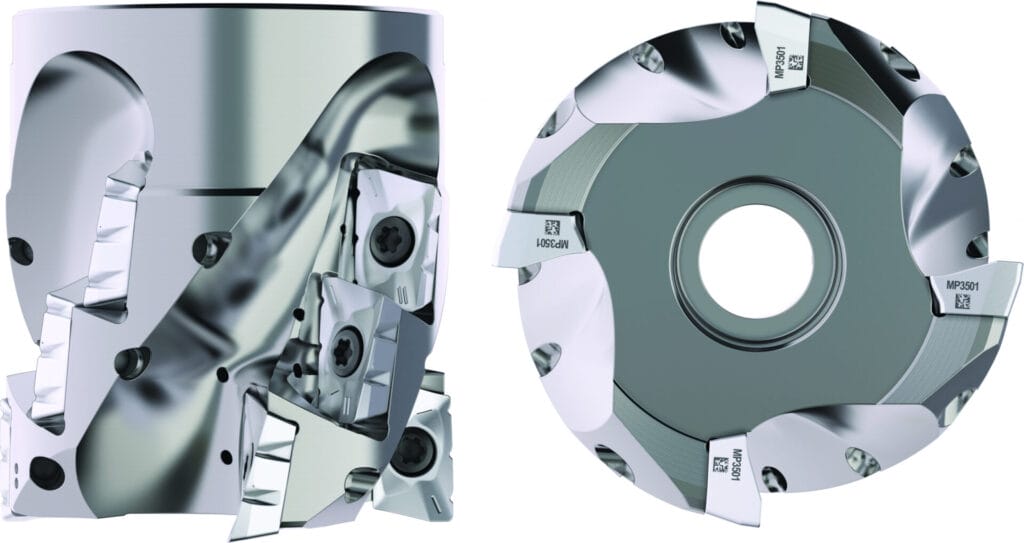

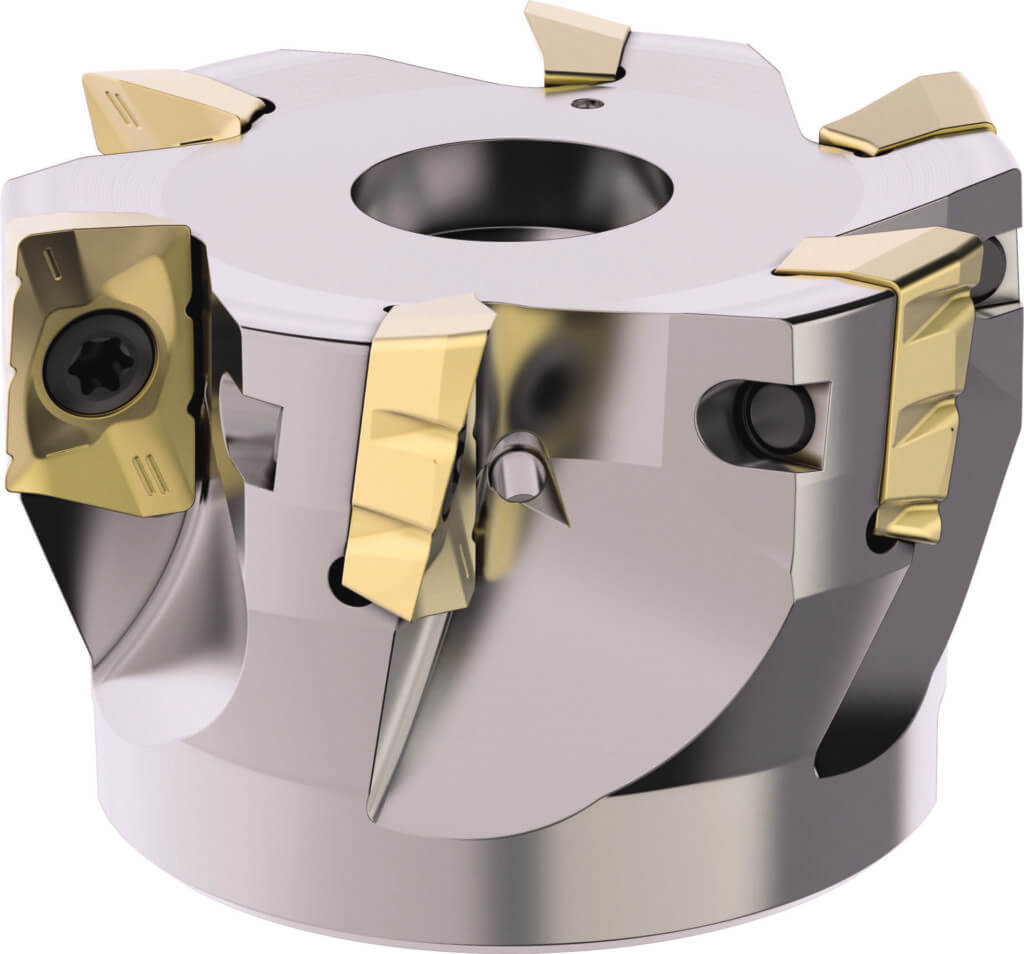

Seco has introduced two new chip splitter milling inserts that lower the stress on both the machine and cutting tool for improved milling process stability. The Turbo 12 and 18 chip splitter inserts for the company’s Turbo cutters – available in five grades for both square shoulder and helical milling cutters – significantly reduce chatter, vibration and stress on manufacturing equipment.

The Turbo 12 and 18 chip splitter inserts incorporate grooves on both of their cutting edges to minimize chip size and reduce cutting forces without reducing cutting data and depth of cut. By keeping chips as small as possible, shops lessen the risk of chip jamming, which improves process security and allows for more effective machining of deep pockets.

Product managers, Magnus Engdahl and Michael Davies work in tandem and spearhead the team who developed the inserts. “The Turbo 12 and 18 chip splitter milling inserts apply to various machining applications and materials,” said Engdahl.

“The versatility of the inserts makes them suitable for a wide range of industry segments and materials, providing customers with a flexibility,” adds Davies.

Go deep with confidence

Hard-to-reach part features can pose challenges, and even the most robust combinations of machine and tool can struggle with long overhangs. Seco chip splitter inserts overcome these challenges by effectively evacuating chips from deep pockets for improved chip flow. Plus, Turbo 12 and 18 chip splitter inserts reduce chatter commonly associated with long-reach applications, resulting in longer tool life and better surface finishes.

Stability for unattended operation

Because of their stability and ability to reduce cutting forces, Turbo 12 and 18 chip splitter inserts give shops the much needed process security and reliability required for effective unattended machining operations. As a result, shops increase output while also minimizing stress on the machine and tool.

For the latest innovations and cutting-edge products, visit www.secotools.com.