Marion’s new chopper design delivers increased throughput, easier maintenance and enhanced safety for processors across multiple industries.

Darwen, UK – October 2024 – Leading industrial mixing specialist, Marion Process Solutions, an Advanced Material Processing (AMP) brand, has announced the launch of its newest chopper. Designed to improve mixing processes in industries like food processing, pharmaceuticals and chemicals, this latest innovation is built to address the most common challenges processors face, such as overheating, frequent downtime for repairs and contamination risks.

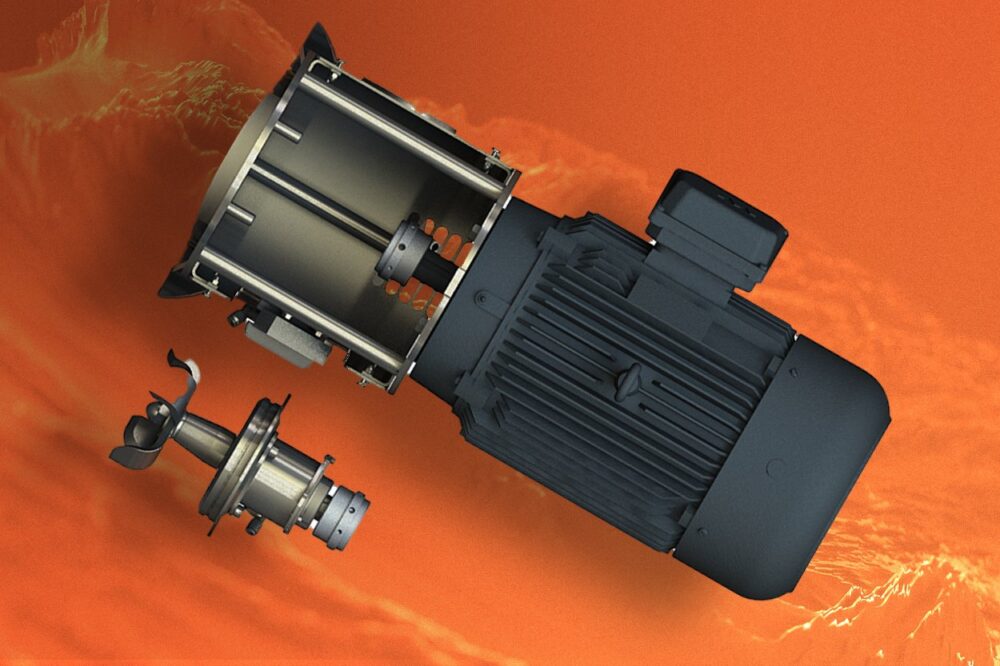

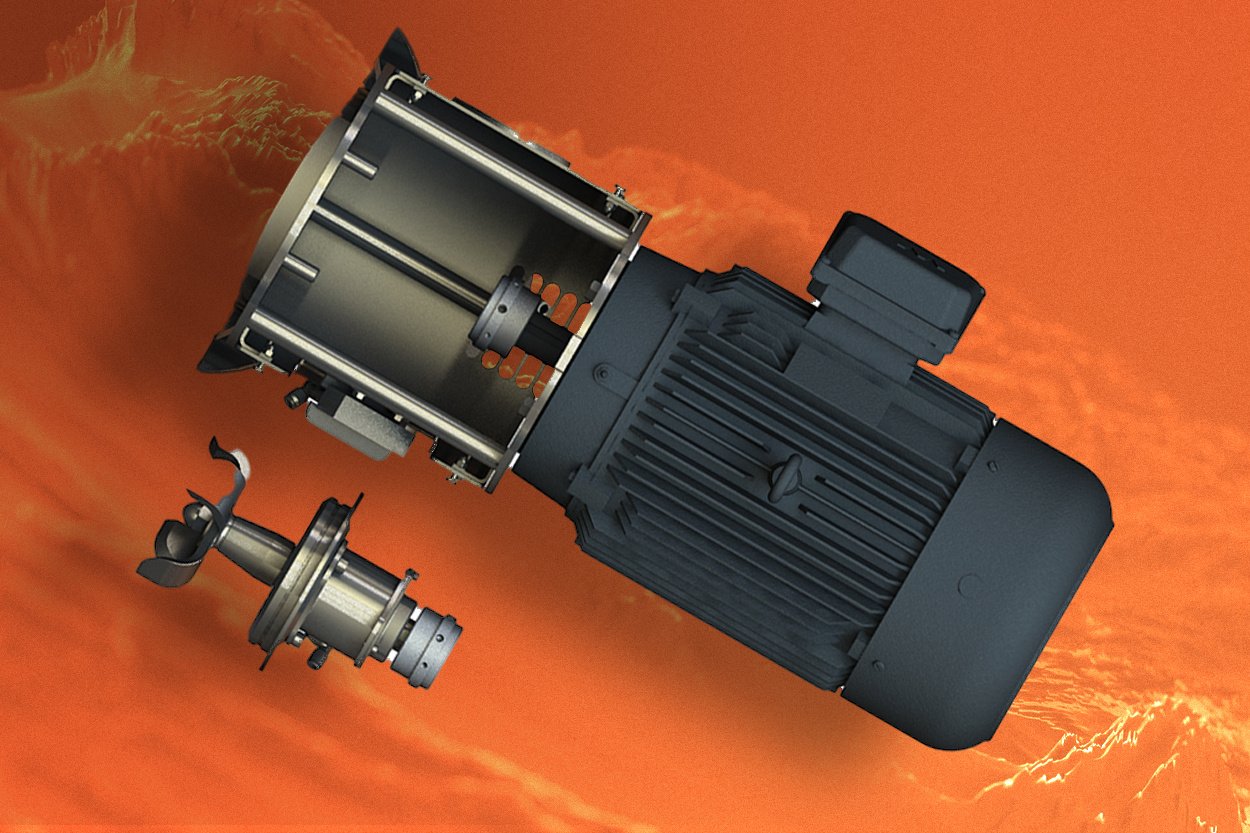

Running at speeds up to 3600 rpm, the chopper effectively reduces lumps and agglomerates and breaks up liquid-rich shot balls, open-matted fibrous materials and distributes pigments. Incorporating a durable, high-speed design, the chopper allows processors to homogenise their mixes faster, while ensuring the equipment runs continuously without overheating. Key to this new design is the integration of more durable shaft seals and bearings, enabling higher throughput rates and less heat generation, therefore reducing the risk of costly downtime through component failure.

“Today’s processors are constantly looking for ways to enhance operational efficiency and our new chopper directly responds to that demand,” said AMP’s CEO, Seth Vance. “With its robust design, our chopper offers faster mixing under consistent conditions, providing processors with a critical edge in productivity and safety.”

The chopper design simplifies maintenance with an all-in-one cartridge assembly that can be easily removed from outside the mixer. This advancement allows for quick changeouts, reducing the time it takes to replace the chopper by 75% – meaning just 15 minutes compared to an average changeout time of one hour. It also eliminates the need for operators to crawl inside the mixer, enhancing worker safety and significantly reducing labor time, as well as personnel required to perform maintenance.

Furthermore, the chopper is designed to prevent product contamination and leaks, which is especially crucial in industries like pharmaceuticals and food processing. The high-speed rotation-rated lip seal and anti-leakage geometry direct the product mix away from sensitive components like the shaft and bearings, therefore reducing the likelihood of leaks and contamination. This design also extends the lifespan of the chopper, ensuring that processors can maintain long-term efficiency while minimising maintenance costs and downtime.

The new Marion chopper is available now and can be customised to meet the specific needs of different processing environments.

Access more information about the new chopper here, or speak with a Marion application engineer here.