From 19 to 21 November, FPT Industrial will be exhibiting at METSTRADE 2024, the world’s leading platform for professionals in the leisure marine equipment industry, being held at RAI Amsterdam Convention Centre.

The Iveco Group Brand dedicated to the design, production and sale of low-environmental impact powertrains will be showcasing its innovative product portfolio for the marine industry, focused on offering ever more reliable and sustainable solutions, alongside the dealer Marant Motortechniek, its authorized distributor for Benelux.

An area at the booth will be dedicated to FPT Industrial Customer Service, where visitors will be able to discover the MyFPT offering – in particular its Connected Solutions, Extended Warranty, and fluids. The MyFPT connected solutions portfolio includes on-board telematics and proactive service, which uses connectivity to monitor marine engines and their performance – e.g. fuel consumption – in real time, maximizing engine uptime and reducing maintenance.

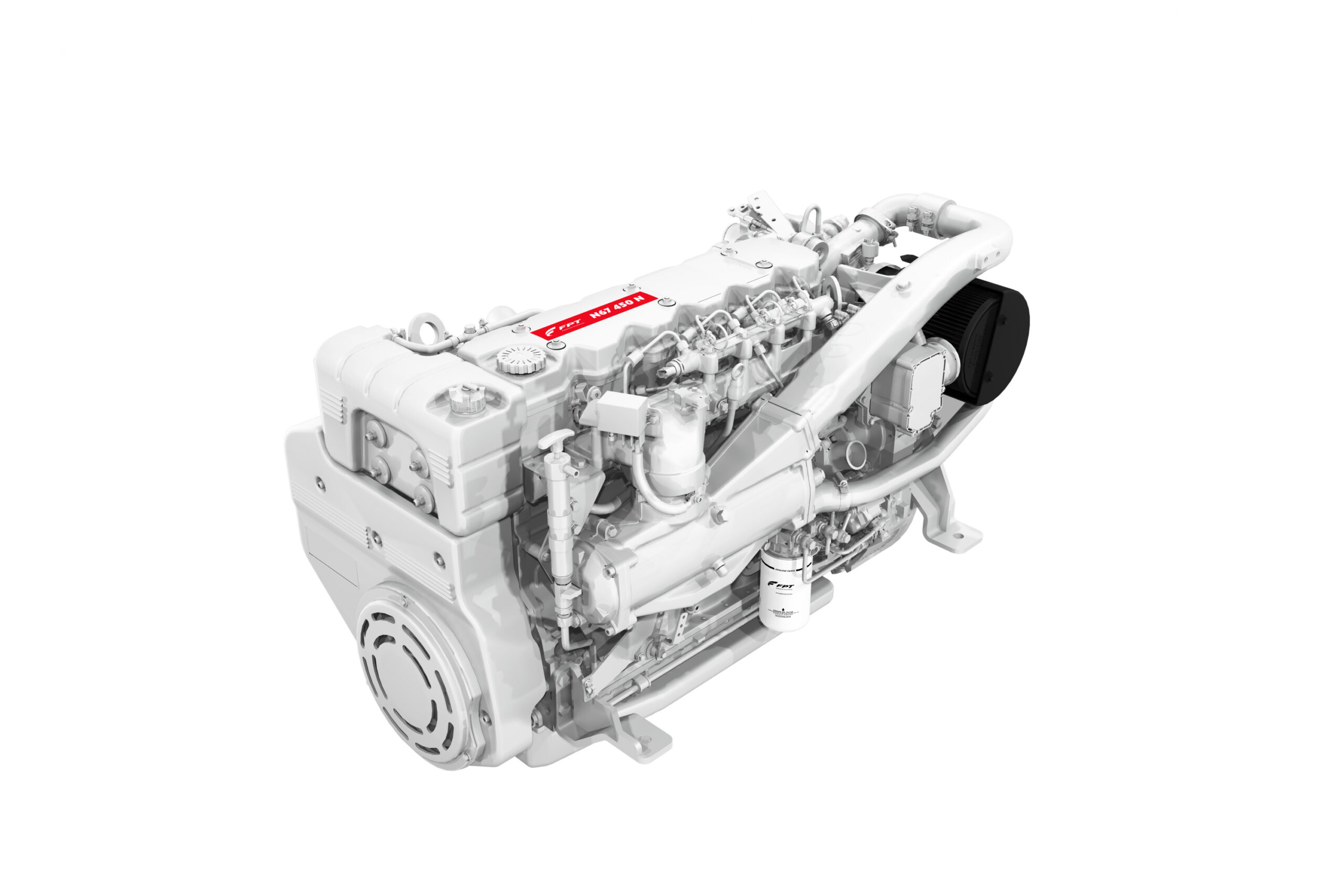

N67 450 N – Introducing a new heavy-duty version of the compact and cost-effective solution from NEF Series

The NEF Series is the most extensive of FPT Industrial’s engine families for pleasure vessels and professional marine duties, with four different displacements from 4 to 6.7 liters, available in mechanical and electronic versions. These engines offer high power outputs, with maximum torque available at low engine speeds, and low fuel consumption, while ensuring maximum performance and reliability, thanks to FPT Industrial’s innovative technologies and production processes.

The version on display at the Brand’s booth will be the N67 450 N heavy duty rated at 215 kW, the latest addition to the power range, designed for the toughest professional missions and capable of unrestricted continuous use.

N67 450 N – Technical Specifications

N67 450 N – Technical SpecificationsArrangement: 6 cyl. in line

Total Displacement (l): 6.7

Maximum Power [kW (hp) @ rpm]: 331 (450) @ 3,000

Heavy Duty Power [kW (hp) @ rpm]: 215 (292) @ 2,000

Thermodynamic cycle: diesel 4-stroke

Air handling: TCA

Cooling configuration: heat exchanger or keel cooling

Direction of Rotation (viewed facing flywheel): counterclockwise

Engine management: electronic

Injection System: CR

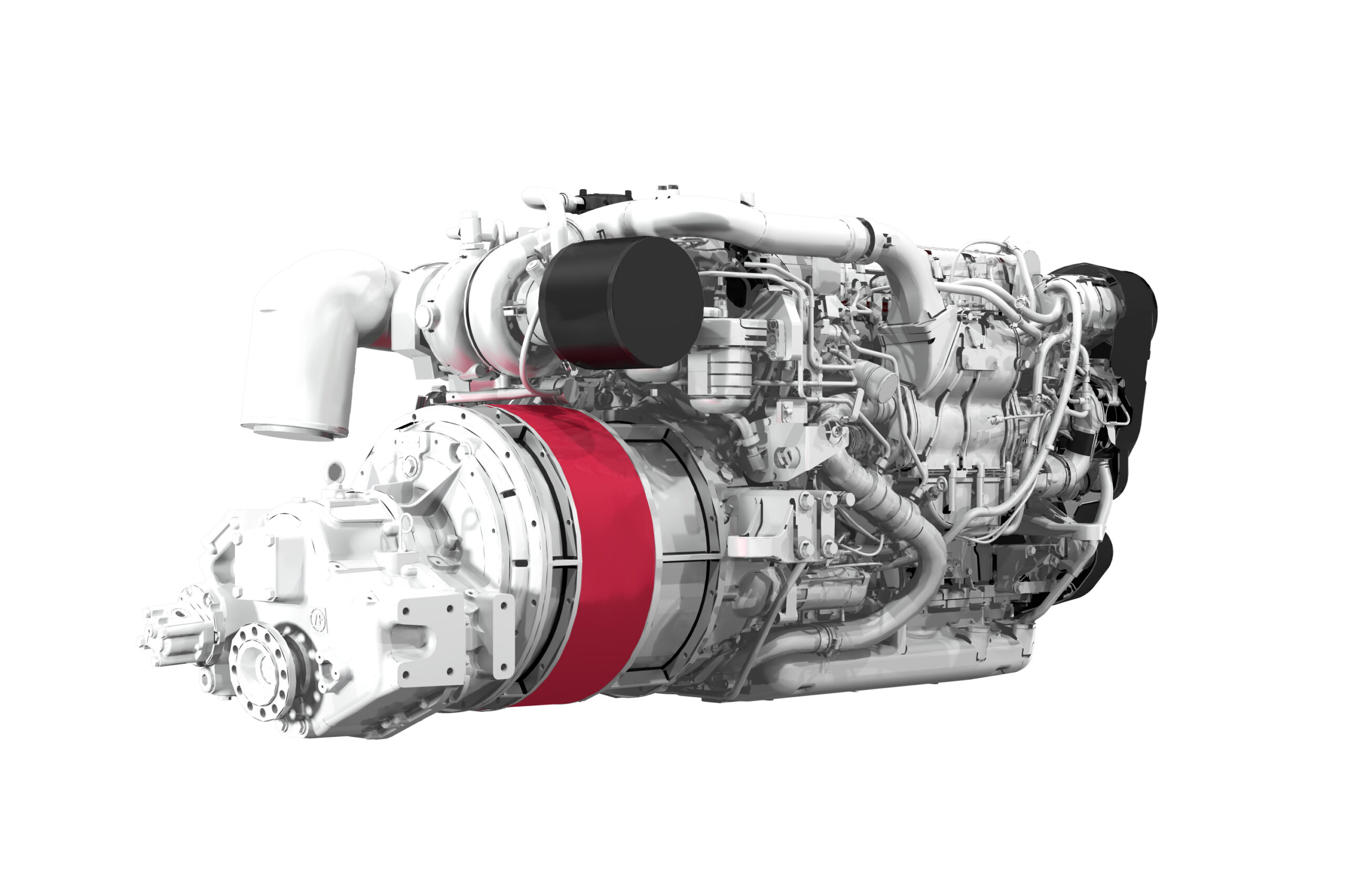

CURSOR 9 650 EVO Hybrid Configuration – Compact, modular and sustainable

Including the hybrid module developed by VULKAN Hybrid Architect for FPT Industrial, the CURSOR 9 650 EVO Hybrid engine is an example of a parallel hybrid-electric marine propulsion system for commercial and pleasure vessels.

The CURSOR 9 650 EVO Hybrid offers a compact, turnkey solution, ideal for small engine rooms and repowering projects, which allows shipbuilders to reduce or eliminate the onboard generator. In addition to the hybrid transmission shown off at the boat show, this turnkey solution is completely integrated with the combustion engine. FPT Industrial’s hybrid marine engines, created in partnership with VULKAN in predefined configurations from 125 kW to 735 kW, offer a wide choice of power outputs for the coupled electric motor (from 96 kW to 250 kW), and modular battery packs.

Designed to be flexible, compact, and modular, the CURSOR 9 650 EVO Hybrid offers top levels of performance and reliability, guaranteeing reduced operating and maintenance costs. Last but not least, it allows full electric cruising, without any emissions or noise, ideal for access to marine protected areas.

CURSOR 9 650 EVO Hybrid configuration – Technical Specifications

CURSOR 9 650 EVO Hybrid configuration – Technical SpecificationsLayout: In-line six-cylinder

Displacement (l): 8.7

Injection system: Common Rail

Maximum engine power [kW (HP) @ rpm]: 478 (650) @ 2,530

Maximum electric motor power [kW (HP) @ rpm]: 200 (272) @ 2,000

Engine dimensions (L* x W x H, mm): 1,226 + 600 mm (for the hybrid module) x 899 x 1,009

Dry weight (kg): 1,014 (ICE) + 380 (hybrid module).

Weight and dimensions of the power management system and battery pack depend on the specific boat requirements and installation.

Emissions certification: IMO Marpol Tier II, RDC St. II, EPA Tier III recreational

* Length at flywheel

CURSOR 16 600 – Custom-made for heavy-duty missions, now also available in fixed-speed auxiliary configuration

In keeping with CURSOR engines’ heritage, extreme robustness, reliability, and maximized productivity are the core of the CURSOR 16 600, available in both propulsion version and fixed-speed auxiliary for G-drive use for IMO Tier 2, EPA Tier 3, China GB2 markets.

The G-Drive version provides 16-liter durability with 13-liter size and weight. Prime Power of 331 kWm @ 1500 rpm and 397 kWm @ 1800 rpm are rated for continuous use, with a 10% overload capability according to ISO 8528, suitable for onboard generators up to 390 KVA 50 Hz and 470 KVA 60 Hz, or fixed-speed diesel-electric propulsion applications. The main options are the new block heater for uses below 0 °C (32 °F), the speed controller, the marine type approval kit, and the front PTO. Heat exchanger and keel-cooling versions are available, while maintenance intervals are at 600 hours.

This recently introduced version of the CURSOR 16 600 delivers the same reliability as the propulsion version, providing abundant energy to larger pleasure vessels and commercial boats.

CURSOR 16 600 – Technical Specifications

Arrangement: 6 cyl. in line

Displacement (l): 15.9

Max Continuous Power [kW (hp) @ rpm]: 441 (600) @ 1,800

Prime Power (capable of 10% overload): 331 kWm @ 1500 rpm / 397 kWm @ 1800 rpm

SCR IMO Tier III Compliant Solution

The result of a partnership between FPT Industrial and Frydenbø Industri AS Marine – authorized Distributor of FPT Industrial’s products and services in Norway and Sweden – this selective catalytic reduction (SCR) system is designed to meet IMO Tier III emission regulations – adopted in areas such as Baltic Sea, the English Channel and the North Sea south of 62 degrees latitude – for FPT Industrial marine engines from 6 to 15.9 liters. This flexible solution enables the maritime industry to reduce its environmental footprint, reducing NOx emissions by more than 70%, and noise, with an average transmission loss of approx. 35dB (A). The weight of less than 300 kg per engine (including urea tank) and the compact design allow for easy installation, operation and maintenance.