At a time when electronic devices dominate every aspect of our daily lives, ensuring their performance and reliability is paramount. Electromagnetic interference (EMI) and radio-frequency interference (RFI) present significant challenges to the functionality of sensitive electronic components, from medical devices to automotive systems and aerospace applications. Effective shielding solutions are essential to mitigate these risks and maintain device performance. Photo-chemical etching (PCE) has emerged as a transformative technology for manufacturing high-quality EMI/RFI shielding components, offering unmatched precision and reliability.

As electronic devices become more compact, powerful, and interconnected, they are increasingly susceptible to interference caused by electromagnetic waves. EMI/RFI shielding serves to block or reduce this interference, safeguarding the performance of critical systems. High-quality shielding ensures uninterrupted communication, enhances signal integrity, and protects devices across a range of different industries.

Jochen Kern, Head of Sales & Marketing at micrometal GmbH, explains, “The precision and intricacy demanded by modern EMI/RFI shielding components are perfectly suited to the capabilities of photo-chemical etching. At micrometal Group, we’re proud to provide cutting-edge solutions that enable manufacturers to meet these growing demands.”

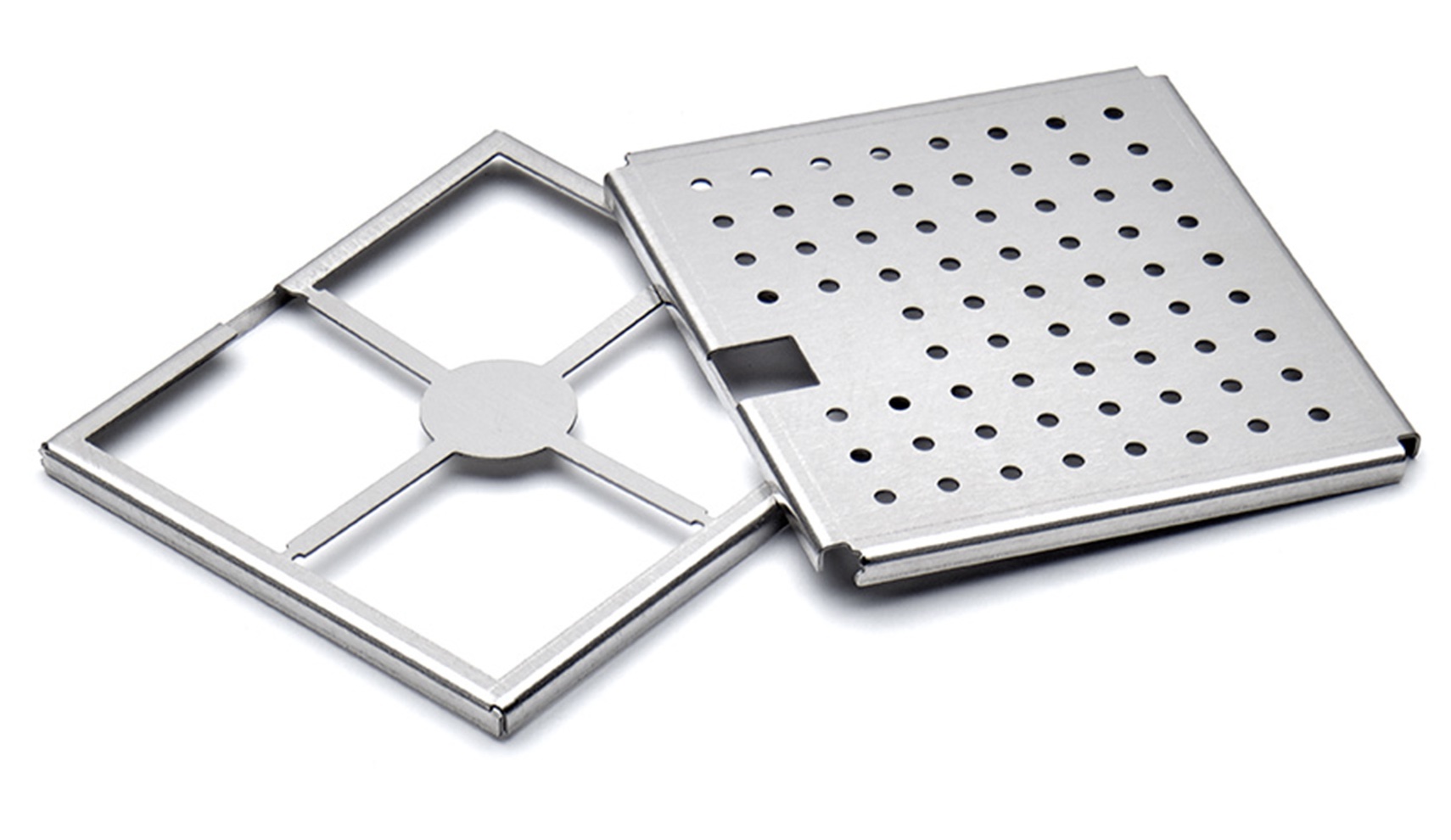

The effectiveness of EMI/RFI shielding hinges on precision and material integrity. Conventional manufacturing methods, such as stamping or laser cutting, often introduce burrs, stress, and material distortion that compromise performance. In contrast, photo-chemical etching provides a tool-free, contactless process that delivers smooth, burr-free edges and uniformity across even the most complex geometries.

With PCE, micrometal Group can produce ultra-thin, lightweight shielding components with features as small as 25 microns. This level of precision is critical for applications like mobile devices, IoT technologies, and aerospace equipment, where space constraints and weight reduction are key factors.

“Photo-chemical etching allows us to meet the most challenging design requirements while maintaining exceptional repeatability and scalability,” adds Kern. “This flexibility makes it the ideal choice for both prototyping and high-volume production of EMI/RFI shielding components.”

EMI/RFI shielding plays a crucial role in consumer electronics (protecting smartphones, laptops, and wearable devices from interference to ensure seamless operation); automotive systems (ensuring reliable performance of advanced driver-assistance systems [ADAS], infotainment systems, and electric vehicle components); medical devices (safeguarding sensitive equipment such as diagnostic machines and wearable health monitors); and aerospace and defence (providing robust shielding for mission-critical systems in harsh environments).

Each of these applications requires precision-engineered shielding solutions that can adapt to intricate designs and tight tolerances — needs that micrometal Group’s PCE fulfills effortlessly.

“With decades of expertise in photo-chemical etching, micrometal Group has established itself as a leader in precision manufacturing. The company’s advanced processes enable the production of shielding components that meet the highest standards of quality, precision, and performance. Manufacturers today face mounting pressure to deliver innovative products quickly and cost-effectively. Our PCE solutions empower them to achieve these goals without compromising on quality,” says Kern.

By combining state-of-the-art technology with a deep commitment to customer collaboration, micrometal Group helps clients overcome the challenges of EMI/RFI shielding in a rapidly evolving landscape.

For those looking to ensure quality and precision in their EMI/RFI shielding solutions, micrometal Group is the partner of choice. Contact micrometal Group today to explore how the company’s photo-chemical etching expertise can help you achieve customer goals.