~ Programmable logic controller offers enhanced performance and seamless connectivity ~

WEG, a global leader in automation and control technologies, has announced the launch of its latest innovation in programmable logic controllers (PLCs) – the PLC500 series. Designed to meet the growing demands of Industry 4.0, the PLC500 offers superior performance, flexible programming and advanced connectivity, making it a vital tool for modern industrial automation.

The PLC500 series builds upon the success of WEG’s previous models, including the PLC200 and PLC410, delivering a significant evolution in processing power, scalability and connectivity. Leveraging cutting-edge WEG technology, the PLC500 integrates seamlessly with the CODESYS® — a globally recognised software platform that allows for intuitive programming and fast migration of existing applications, reducing development time and cost.

“The development of the PLC500 was driven by WEG’s commitment to addressing key industry challenges including the need for enhanced connectivity, flexibility and energy efficiency,” said Aluisio João Corrêa, international sales manager for products including low voltage (LV) drives and controls at WEG.

“The PLC500’s modular design supports scalability, making it ideal for original equipment manufacturers (OEMs) and diverse automation processes. The real-time Internet of Things (IoT) monitoring tools and predictive maintenance features embedded in the PLC500 help reduce downtime, optimise operations and lower operational costs.”

High performance and connectivity

Powered by a Dual-core ARM Cortex-A7 processor running at 1 GHz and a real-time ARM Cortex-M4 coprocessor operating at 200 MHz, the PLC500 offers 1 GB RAM and 4 GB flash memory, ensuring it can handle complex industrial applications and multiple simultaneous tasks with ease.

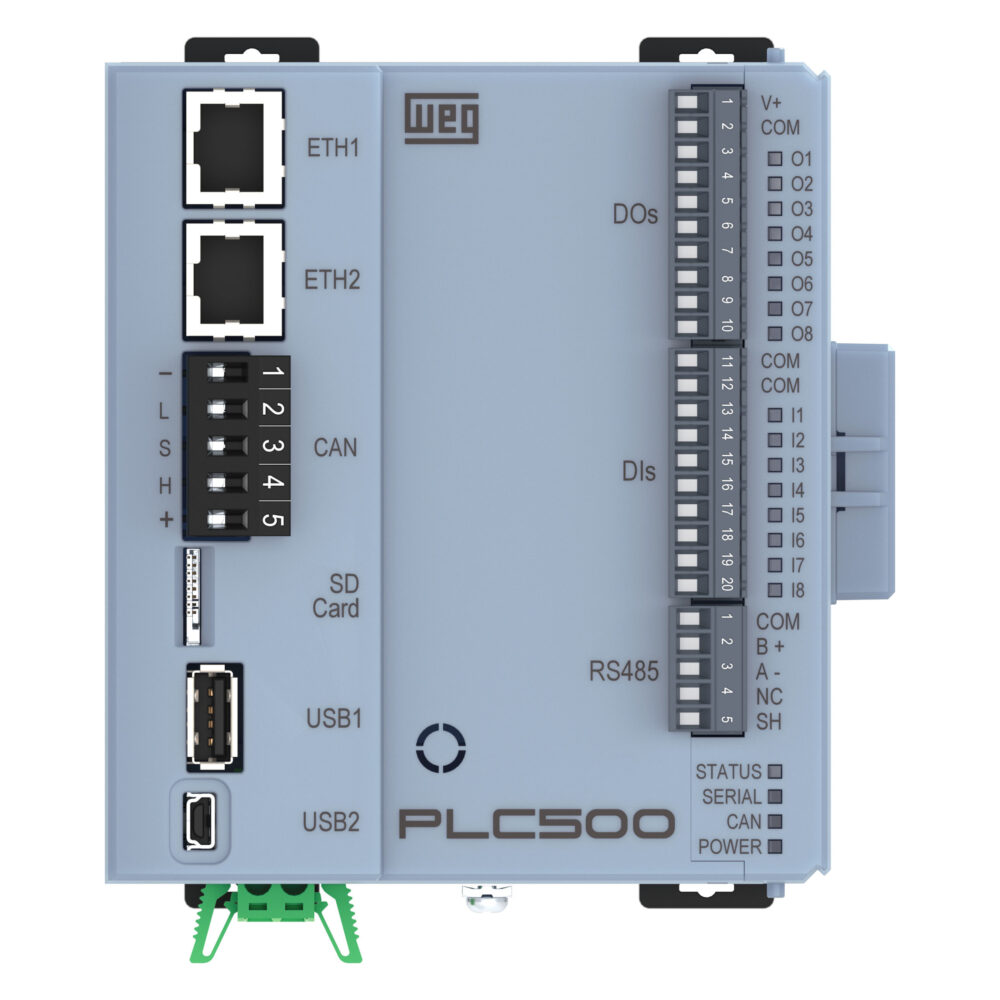

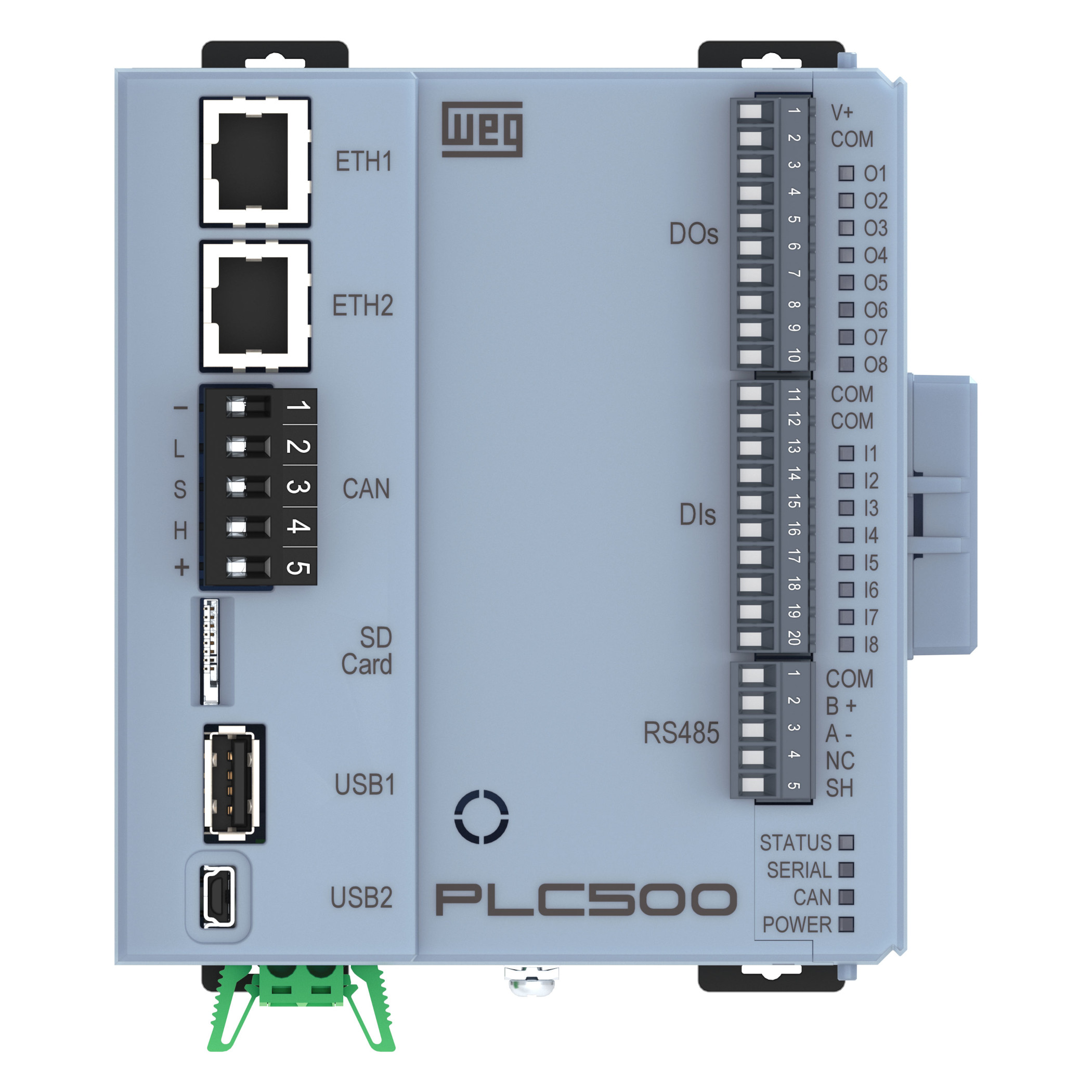

One of the standout features of the PLC500 is its robust connectivity options. It includes two Ethernet ports, one Controller Area Network (CAN) port and one RS485 port, allowing it to operate efficiently across various communication protocols such as Modbus Transmission Control Protocol (TCP)/Remote Terminal Unit (RTU), Ethernet/Industrial Protocol (IP) and PROFINET.

Additionally, specialised versions of the PLC500 are available, including the PLC500MC for servo movement control and the PLC500ED, which integrates advanced edge computing technology.

WEG’s PLC500 series is a next-gen controller for Industry 4.0, offering advanced connectivity, scalability and energy efficiency.

Proven versatility across industries

“The PLC500 has already proven to be a valuable asset across a wide range of industries, including food and beverage, textiles and general manufacturing,” said Corrêa. “Its versatility makes it suitable for OEMs and automation processes across various sectors, demonstrating its effectiveness in both specialised applications and broader industrial environments.”

Compared to other models in WEG’s lineup and those of competitors, the PLC500 series stands out with its compact design, making it easy to install even in tight spaces. With support for over 200 local input/outputs (I/Os) and thousands of remote I/Os, the PLC500 offers unparalleled flexibility and integration options, positioning it as a leader in the industrial automation sector.

Early adopters of the PLC500 have praised its user-friendly interface, intuitive programming and seamless system integration. Performance feedback highlights its speed and reliability in real-world applications, further solidifying its role as a transformative solution in industrial automation.

Looking ahead, WEG plans to continue advancing the PLC500 series, aligning future developments with emerging market trends and customer needs. WEG remains dedicated to supporting industries in reducing energy consumption and carbon emissions, reinforcing its commitment to sustainable practices.

For more information on the PLC500 series and other automation products, visit its website or contact WEG’s sales team at [email protected].