Contaminant detection and food checkweighing specialist Fortress Technology Europe continues to add to its user-friendly and waste-saving portfolio of machinery with the addition of a new upstream in-line food processing checkweigher.

Designed for automated raw ingredient processing lines, the launch of the hygienic Raptor Inline Checkweigher gives bakery, meat, seafood and prepared food manufacturers an efficient, in-motion weighing system that connects to upstream portion control equipment. Simple to integrate into existing production lines, including alongside sausage stuffers, meat and plant-based burger forming and portioning lines, cheese cutters, as well as bread, pizza and cake dough dividers, the Raptor Inline Checkweigher guarantees uniform portion weights at rates exceeding 9,000 units per hour.

Engineered originally for high speed bakeries, this new addition to the Fortress Raptor Checkweighing series gives European food processors the tools to switch out their manual weight checking processes and maintain weight compliance while simultaneously savings thousands of pounds in daily product giveaway.

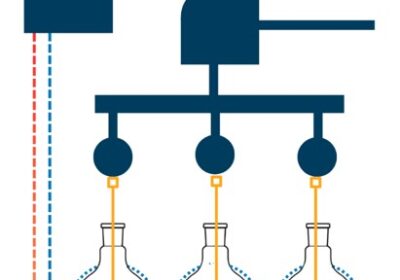

Capable of weighing items as light as a garlic dough ball up to a 6kg cheese block, and everything in between, the new Raptor Inline Checkweigher automatically rejects product units under or over-weight by as little as 0.5 grams. Simultaneously, the machine’s advanced fibre optic controlled software communicates back to upstream portion control equipment in real time to adjust the position of cutting blades. Helping to ensure the entire batch isn’t off-spec.

- : To keep the Raptor Inline Checkweigher compact, the reject unit sits beneath the conveyor within the body of the machine.

- Designed for automated raw ingredient processing lines, Raptor Inline Checkweigher gives food manufacturers an efficient, in-motion weighing system that connects to upstream portion control equipment.

Catch before the batch

Given the focus on manufacturing waste, identifying and actioning under or over weight products before the energy intensive process of baking or placing into expensive packaging is more imperative than ever, highlights Fortress Europe’s Applications Engineer Daniel Shail. “Leaving the weight check until the end of the process is one of the most wasteful activities as it could result in an entire consignment of baked or packaged products being recalled, not to mention the many hours wasted in production and workforce salaries.”

A large number of food processors continue to check units within batches randomly by hand. Not only is this labour intensive, but it can also lead to significant variations in product quality, cautions Daniel.

Automated inline checkweighing allows for individual pieces that are off target weight to be removed and reworked, as well as providing corrective feedback to the upstream portioning equipment.

Daniel continues: “Weighing raw product on the conveyor line without removing it to place on a separate scale is the most efficient method. It also mitigates against potential human contaminants. For products with a number of processing variables, such as different densities, lean-to-fat ratios and even live raw bread dough, these different weight variations all need to be factored in.”

The Raptor Inline Checkweigher’s ultra-hygienic washdown design with a Clean-in-Place (CIP) mode, has been engineered for easy and deep sanitation to prevent cross contact contamination. Specifically, the tight-fitting conveyor and Fortress Technology’s unique ‘no-tool’ conveyor removal innovation overcomes the longstanding industry challenge of loosening belt tension during cleaning and maintenance. In just seconds, operators can unclip and disconnect the conveyor motor and lift out the entire conveyor assembly. This allows for the belt support frame to be fully-sanitised too, reducing the build-up of loose product. Belt tension and alignment are instantly restored when clipped back into place.

To keep the Raptor Inline Checkweigher compact, Fortress Europe engineered the reject unit to sit beneath the conveyor within the body of the machine. If the checkweigher identifies products that don’t meet the target weight specifications, the conveyor dips, dropping products into an equally hygienic and lockable BRC-approved reject bin. Enabling line operatives at regular interviews to open, remove and place the product back upstream for re-portioning.

Addressing the potential issue of airflow negatively influencing weighing accuracy or airborne contaminants landing on raw ingredients, the Raptor Inline Checkweigher also features an interlocked conveyor cover with special engineered cut outs.

Demanding data

Data gathered via the Raptor’s management control system can also help to track uptime and address line inefficiencies. Using the swipe touchscreen, processors can select the statistical parameters most relevant to their operation, including giveaway by weight and percentage, portions per minute, rejected product numbers etc.

The easy to use graphical display automatically logs and reports Reject Integrity compliance tests. This intuitive digital interface also helps to significantly reduce set up time between each batch.

For enhanced traceability, reports – configured by time, date or product code – can be downloaded and easily converted to common management reporting and software applications. Secure remote and authorised access levels ensure processors have all the tools needed to troubleshoot, diagnose and resolve equipment issues on the spot and minimise system downtime.