Director Chris Yapp discusses the company’s pioneering journey in sustainable packaging with its non-plastic, cold-sealed tray system. He was one of the inaugural Future Trailblazer winners at Packaging Innovations & Empack 2024.

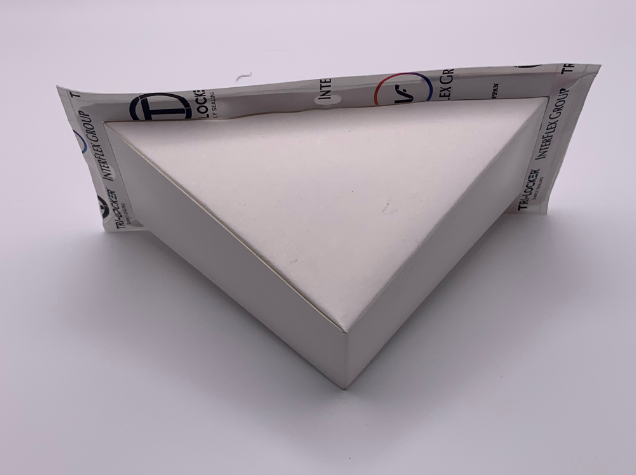

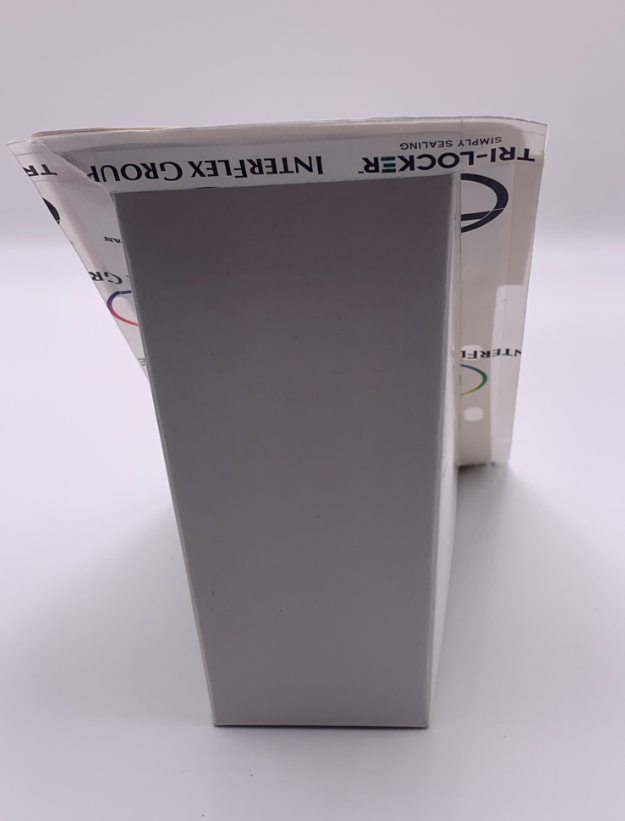

Innovation often begins with a simple idea but transforming that idea into a market-ready product is challenging. TRI-LOCKER exemplifies this arduous path with its breakthrough in sustainable packaging—a non-plastic sealed tray system that combines convenience with environmental responsibility. Director Chris Yapp’s determination to eliminate plastic and the need for heat sealing drove the development of TRI-LOCKER’s advanced cold seal technology, resulting in a product that simplifies packaging while addressing significant ecological concerns.

Bringing TRI-LOCKER to the verge of commercial viability has involved overcoming numerous obstacles. Extensive research and development were necessary to perfect the technology and meet stringent quality and safety standards. Securing patents, conducting rigorous testing, and navigating regulatory requirements added further complexity to the process. Each step demanded not just technical expertise but also unwavering commitment and resilience.

Yet, Chris’s vision of revolutionising packaging kept the team focused and driven. Despite the inherent difficulties, TRI-LOCKER’’s journey from concept to the brink of market readiness highlights the essence of innovation—turning an idea into a tangible solution that makes a real difference. It is a testament to the hard work and dedication required to bring sustainable, practical products to consumers.

“Things like this happen because we wanted to make a change and saw a technical solution,” he tells Packaging Innovations & Empack. “It’s whether we are willing to put things in motion to take advantage of that opportunity. TRI-LOCKER is something that didn’t exist before but does now. You’re either in the camp of ‘can do’ or ‘can’t do, just because it hasn’t been done before doesn’t mean it’s wrong, when the car was invented people just wanted a faster horse.

“TRI-LOCKER started with Mike and I developing food packaging that could be sealed without heat and non-sustainable polymers.

“Our message to interested parties is ‘We’re not going to heat seal,’ when most manufacturers use heat seal, so you’ll turn the heat off, improve your carbon footprint and a make a significant saving on your electricity bills. I think consumers are more savvy about good environmental choices than manufacturers give them credit for.

“So, while plastic might be sent off to be recycled and collected in supermarkets, what happens to it afterwards? A Bloomberg reporter documented, that plastic films from the UK are burned for fuel in cement making process in Europe. TRI-LOCKER is offering a simpler, more circular alternative to plastic and this is what is being driven around the globe by all governments.”

“TRI-LOCKER has a granted UK patent and granted US patent with the European patent very close to being granted. We know that paper can be repulped, reused, and at the end of the lifecycle turned into fertilizer, as we all know trees regrow. It’s a strong unambiguous message.”

TRI-LOCKER’s packaging solution offers numerous benefits, including improved seal integrity, lower electricity usage, and the potential to cut the use of non-sustainable polymers by up to 99%. The company’s technology ensures that seals are achieved through pressure rather than heat, making sealing both efficient and reliable. This innovation aligns with consumer demands for sustainable packaging and provides a practical, recyclable alternative to traditional plastic packaging.

TRI-LOCKER’s journey, driven by Director Chris Yapp’s vision, reflects a dedication to creating impactful and sustainable packaging solutions that address significant ecological concerns.

Despite securing patents and garnering interest from multinational companies, Yapp discovered that convincing food manufacturers, rather than retailers, is crucial. Manufacturers often resist change due to existing investments and historical efficiency targets. Still, when they see the benefits of TRI-LOCKER’s cold seal technology—such as reduced seal failure rates, lower electricity use, and significant reductions in plastic use—they are willing to try it. This journey, spanning years of product development and overcoming numerous challenges, underscores the necessity of cost-effective and sustainable solutions in the packaging industry.

“Every day is a school day,” he continues. “It’s amazing what surprises me. What amazes me is that there has to be a desire for change. And I think the key is knowing that we’ve innovated the best solution to a global problem. We have had tremendous support in this goal from major manufacturing companies who offer their tangible support towards the success of TRI-LOCKER. We have non-disclosure agreements in place with almost all retailers. Engaging with manufacturers, we find that there is resistance to packing line changes. They’ve invested heavily in heat sealing equipment across numerous sites and want to protect the status quo.

“However, when you connect with the right people and explain how our system improves seal failure rates without relying on precise temperature settings—just pressure, with a cold seal that sticks only to itself—interest sparks. We offer consistent seal quality, significant reduction in electricity use, reduced carbon emissions, cold tool changeovers, reduced tooling costs (no heat), no additional material costs, and the potential to cut plastics use by up to 99%. This resonates, and suddenly, someone says, ‘Let’s try it.’ That’s all it takes. Introduce them to our partners, and things progress. It’s taken two-and-a-half years since 2022, mostly under wraps for product development and design. Even sourcing materials was a challenge. Looking back, it’s been amazing, without boasting. We used to joke, ‘We’re just two guys from Shropshire.’ There is no need to mention that now, especially with our US patent granted after rigorous examination. Some days are tougher, but change is necessary and must be cost-effective.”

As TRI-LOCKER prepares to showcase its groundbreaking solutions at Packaging Innovations & Empack in February 2025, the event is a pivotal platform to highlight its technological advancements and foster industry-wide transformation. It will be an opportunity for TRI-LOCKER to engage with stakeholders, demonstrate their products’ capabilities, and catalyse broader adoption of sustainable packaging practices.

Innovation isn’t just about creating something new; it’s about challenging the status quo and driving meaningful change. For inventors and company founders, their creations are more than just products. Criticism, though inevitable, isn’t taken personally; rather, it drives improvement and evolution.

“When you’re an inventor or company founder, you treat it like your child and want to protect it,” opens Chris. “No one likes their child being criticised. But we don’t take it personally.

“Many Packaging Development Technologists and Brand Holders should be reaching out to us to discuss TRI-LOCKER. Are we so attached to plastic food trays as a global society that we can’t consider alternatives? We can’t hermetically seal our trays, so we know we can’t apply TRI-LOCKER to 100% of the market. But there are many products we can address. Regulations are in place e.g. pEPR where there will be financial penalties for packs with dubious recycling credentials.”

Central to this discourse is navigating the delicate balance between granting exclusivity rights to retailers versus manufacturers. Exclusivity for retailers risks limiting market access and stifling competitive diversity, potentially impeding the widespread adoption of sustainable practices. Conversely, empowering large-scale food manufacturers with exclusivity could drive substantial industry shifts by aligning production incentives with environmental stewardship. According to Yapp, this strategic approach fosters innovation. It encourages broader retailer engagement, allowing non-partnered retailers to express interest and advocate for access to eco-friendly solutions like TRI-LOCKER.

“Wouldn’t it be lovely to know that TRI-LOCKER is going to save the turtles and it’s a green initiative that should be available to all?” he says. “There’s a part of me that feels that way. However, I’m not naive. Regardless of what happens with packaging in the UK, there’s still a lot of unrecycled packaging worldwide. There is a global issue with packaging disposal.

“Giving exclusivity to a retailer wouldn’t be beneficial. However, giving exclusivity to a large food manufacturer supplying multiple retailers could drive change. Retailers not currently provided by that manufacturer but interested in TRI-LOCKER could request it. Food manufacturers are innovators searching for the next big thing.

“The change from plastic trays to vacuum packing minced beef. As someone from a food background, I know vacuum-packed meats don’t look appealing. I’m used to unpacking and using vacuum-packed goods, but those smaller retail packs aren’t visually appealing. It would be interesting to see the sales impact of the switch from plastic to vacuum packing. Did it boost sales? Moving from recyclable packaging with a film lid to 100% non-recyclable packaging suggests green credentials may have been more about cost savings. It’s a cheaper format but may not visually appeal to consumers who then have to discard it in their black bins. So, was it really about cost savings? Those of us in packaging understand the greenwashing that’s happening.”

In the high-altitude world of airline meal packaging, innovation isn’t just a luxury—it’s a necessity driven by environmental responsibility and regulatory compliance. The challenge of waste compaction during long-haul flights has emerged as a critical issue, spotlighted vividly at WTCE in Hamburg.

Amidst this backdrop of environmental concern, TRI-LOCKER has emerged as a beacon of sustainable innovation. Its unique mono material and cold seal adhesive redefine packaging durability and integrate seamlessly into existing recycling streams—a feat that distinguishes it in an industry grappling with waste management and regulatory compliance complexities.

“In the airline sector, we’re engaging with people facing their biggest challenge on long-haul flights: waste compaction,” he continued. “I was shocked to see compaction boxes sold. Some were PE-lined, some not. They compact everything onboard, from sandwiches to napkins, reducing volume for storage but creating significant waste when they land that’s then destined for either landfill or incineration.

“This issue might not be widely known, but according to waste management associations, it’s a significant problem. Due to biosecurity concerns, EU regulations dictate that any food-based waste from outside the EU must be incinerated.

“The genius of TRI-LOCKER lies in its mono material and cold seal adhesive. There are more non sustainable polymers in the ink printed on the packaging than in TRI-LOCKER seal system itself. All these elements are managed within regular recycling streams. So, we’re proposing to the airline sector, including Dnata, En Route, Gate Gourmet, and directly with airlines; using TRI-LOCKER -sealed trays that are manufactured from cold-sealed cardboard is a new approach. These trays can compact food waste, potentially turning it into biomass that can produce gas for energy generation, along with a byproduct of fertiliser. In addition, if all drinks mainly in aluminum are the recycled separately a solution could exist.

“In the US, we’ve secured patents, and discussions suggest they prefer biodegradability over cleaning packaging resources, unlike in the UK where recycling is the main objective. Their focus is on biodegradability. The US market may embrace TRI-LOCKER sooner than the UK. Though Mike and I, with our manufacturing partners, focus on the UK, our US patent allows us to work with our global manufacturers. With PR and awareness, TRI-LOCKER’s potential in the US could surpass its UK debut.”

As the discourse on sustainable packaging in the airline industry gains momentum, parallels can be drawn to broader retail trends where the balance between consumer expectations and environmental impact constantly evolves. Reflecting on innovations like Tri Locker’s biodegradable solutions, which promise functionality and sustainability, prompts a critical question: should retailers prioritise environmental stewardship over traditional product visibility via plastics inherent transparency?

“At some point, all retailers, should trust their consumers enough to prioritise removing plastic over full product visibility because of consumer brand loyalty.

“Retailers should be brave enough to say, ‘You can’t see the product as clearly as with plastic, but there is no plastic.’ Being honest with consumers will likely gain their trust.

“We need strategic decision-makers to step up. Perhaps legislation will push this change through. We will adopt these practices with the Single-Use Plastics Directive, especially if we get closer to Europe under a Labour government. For example, in France, McDonald’s is moving away from single-use packaging and looking at reusable options.

“It’s all a bit of a crystal ball gazing as to what will happen, but there is hope that we will make these necessary changes. The status quo is not an option.”

As platforms for future packaging innovations, events like Packaging Innovations & Empack in 2025 are pivotal catalysts for industry transformation and aid the likes of TRI-LOCKER with its aims. These gatherings showcase cutting-edge technologies and sustainable solutions and serve as breeding grounds for game-changing innovations.

TRI-LOCKER finds itself at a critical tipping point in terms of global adoption of its revolutionary packaging solution. With its biodegradable materials and innovative sealing technologies, TRI-LOCKER meets and exceeds the growing demand for sustainable packaging options across various industries. As global awareness and urgency around sustainability grow, TRI-LOCKER’s role as a catalyst for change becomes increasingly pivotal, driving widespread adoption and reshaping industry standards for years.