~ Manufacturers can reduce material waste and enhance product quality ~

Research by the National Association of Manufacturers (NAM) found that 58 per cent of manufacturers considered sustainability essential for competitiveness. Sustainability is a strategic imperative, including in material handling processes. Here, Carl Hodges, business development manager at Gough Engineering, the materials handling specialist, explores five ways manufacturers can reduce their environmental footprint.

NAM’s research, conducted in 2022, marked a sharp increase from 38 per cent the previous year, demonstrating that sustainability is moving up manufacturers’ agendas. However, manufacturers face a dual challenge in their pursuit of sustainability: balancing environmental goals with operational efficiency and cost-effectiveness.

Transitioning to greener practices often requires substantial investments in new technologies or equipment, which can pose financial challenges and disrupt established workflows. Despite these hurdles, integrating sustainable solutions into material handling processes is crucial for reducing environmental impact and maintaining competitiveness.

Here, we delve into five methods through which material handling equipment can advance sustainability while enhancing operational efficiency.

- Lowering energy consumption

Reducing energy consumption is pivotal to sustainable manufacturing practices. Energy-efficient equipment, such as motors equipped with variable frequency drives (VFDs) and high-efficiency conveyor systems, plays a critical role in achieving this goal. VFDs allow precise control over motor speed and torque, optimising energy usage during varying operational demands.

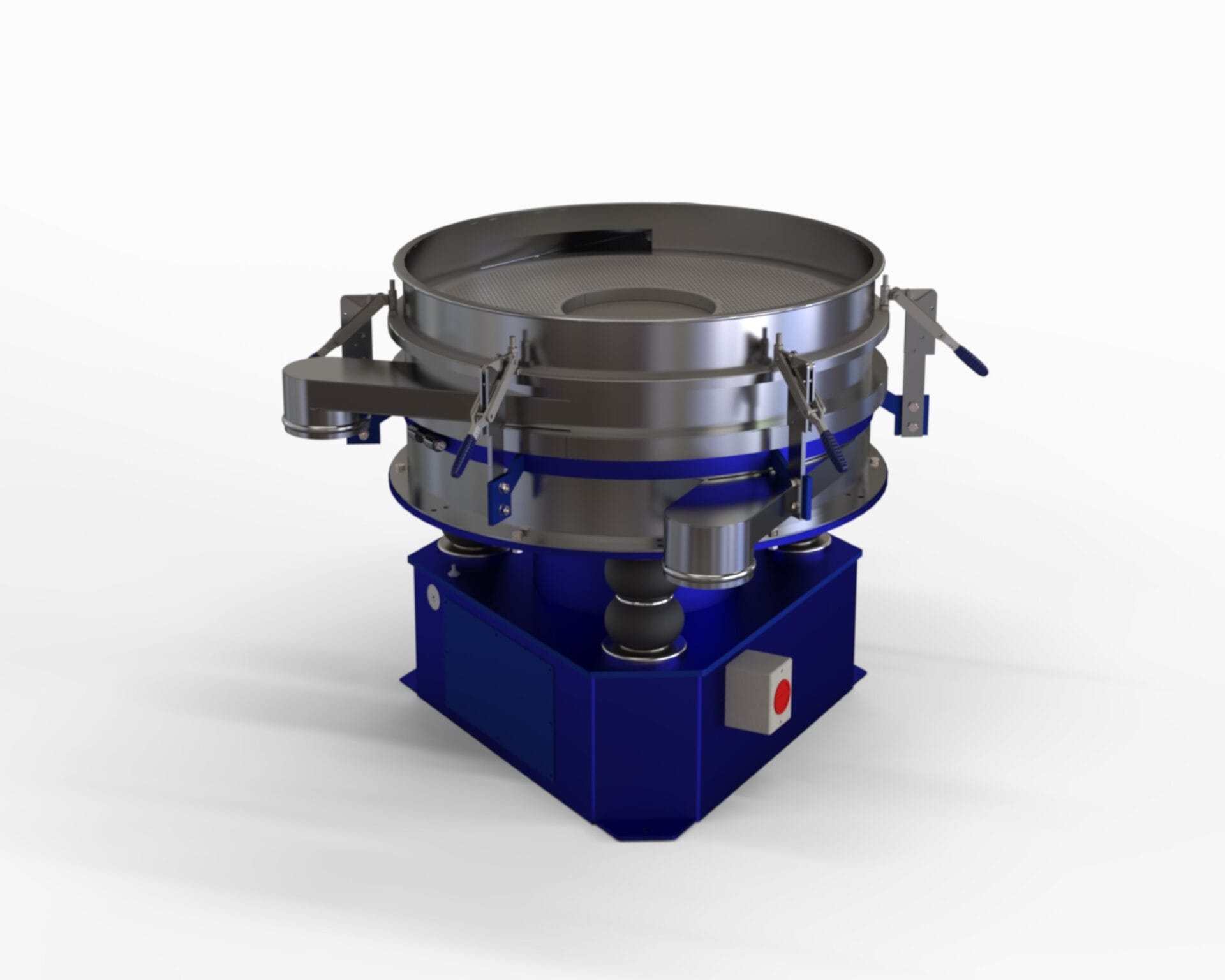

Gough Engineering’s Vibrecon® vibratory separators exemplify energy-efficient design. Engineered to minimise power consumption while transferring product efficiently, these separators utilise advanced vibratory technology tailored to specific material handling requirements. This gives consistent, reliable performance so motors run smoothly and efficiently, minimising environmental impact. The approach not only reduces operational costs but also contributes to a lower carbon footprint while securing production quality objectives.

- Reducing material waste

Effective management of material waste is imperative for sustainable manufacturing. Accumulated waste and spillage can create risk zones that affect not only the wear and overload on mechanical systems and safety risks for operators, but also pose potential fire hazards for certain materials.

To mitigate these effects, industrial sieves, such as vibratory and centrifugal separators, are instrumental in classifying and sorting raw materials, ensuring uniformity and minimising waste during production processes.

In a recent project for Gough Engineering, a pharmaceutical manufacturer wanted to optimise their production line efficiency. By integrating vibratory screening equipment, the manufacturer achieved precise separation of active pharmaceutical ingredients (APIs), while recovering product that was unfit for further processing and then recycling or reconditioning it within the production infeed lines. This process reduced material waste and enhanced product quality.

- Preventing leakages and spillage

Minimising leakages and spillage is a critical aspect of sustainable material handling, as it directly impacts both resource conservation and safety. An example of this in practice is tubular feeders in handling fine powders. These systems are designed with sealed tubes and extraction points to ensure that no dust escapes into the atmosphere.

The enclosed design prevents product spillage and contamination, thus safeguarding the integrity of the material being handled and reducing the risk of potential hazards associated with airborne dust. This focus on minimising leakages not only enhances operational efficiency but also contributes to a more sustainable and environmentally friendly production process.

- Precise control over product transfer

Precision in material handling not only minimises waste but also supports recycling efforts and promotes resource efficiency. Advanced vibratory separators, such as the Vibrecon® GVC5 with a diameter of 1,380mm, offer precise particle size classification, facilitating the recycling of materials within food, chemicals, plastics and other suitable products.

A recycling facility in Norfolk, UK, implemented Gough Engineering’s Vibrecon® GVC5 separator to process glass fibers efficiently. The system’s dual-deck design allowed for effective separation of oversize particles, fine materials and quality fibers, contributing to enhanced recycling rates and reduced landfill waste.

- Minimising downtime through easy maintenance

Reliable equipment operation is fundamental to sustainable manufacturing practices. Material handling solutions engineered for easy maintenance, with robust components and proactive service support, ensure continuous operation and minimal downtime.

It’s important to partner with a material handling specialist that provides comprehensive maintenance programs that include regular service checks and component replacements to optimise equipment performance and longevity. By adhering to service schedules, manufacturers mitigate operational disruptions and maintain high productivity levels with excellent machine performance and utilisation.

By implementing these five strategic steps towards sustainable material handling, manufacturers not only reduce their environmental footprint but also enhance operational efficiency and competitiveness in a rapidly evolving market.

To learn more about how Gough Engineering’s material handling equipment can benefit sustainability initiatives, visit its website.