Following the successful Jupiter Icy Moons Explorer (JUICE) mission launch, which included parts printed on a Renishaw RenAM 500 series metal Additive Manufacturing (AM) system, Marc Gardon, AM Applications Manager at global engineering technologies company Renishaw, spoke to the team at aerospace design and manufacturing expert, CiTD. Here, Marc, Marta García-Cosío Carmena, CiTD Managing Director, and Lidia Hernández Álvarez, CiTD Head of Additive Manufacturing, share their thoughts.

Advancements in technologies such as sensors and microprocessors has led to the miniaturisation of components for communication, data processing and more. Combined with the development of new composites, such as carbon fibre and other lightweight alloys, it has become easier to develop smaller, more affordable satellite platforms. As a result, space agencies and research institutions are now not the only companies operating in the space industry, with many private companies looking to develop the commercial opportunity to provide services for smaller satellites.

The space industry differs from other sectors, such as consumer goods or commercial aerospace, because of production rates. Space agencies will develop individual satellites during a project, while small companies will produce small batches of components — manufacturers will rarely produce more than 100 units, and every product will be highly customised. As a manufacturing method, metal AM is well suited to rapid prototyping and the low-volume production of highly customised parts, so there is a clear opportunity for manufacturers in this sector to embrace AM technology.

Finding the right balance

“As the industry becomes more competitive, reducing lead times and costs while maintaining quality and reliability will continue to be a key challenge,” explains García-Cosío Carmena. “We now have access to a range of new manufacturing methods and materials that mean we can design optimal parts for a range of applications. However, to have the skills and technologies available to develop platforms quickly to the tight tolerances required in aerospace, can be costly for companies.

“To find the right balance between cost and efficiency, manufacturers should take the time to understand all operational requirements at the outset of the project. Space satellite platforms must meet tight tolerances to ensure performance and precision — any deviation when operating in a harsh environment like space can lead to malfunction and even mission failure. As a result, manufacturers often have to deliver under pressure to meet deadlines and stay ahead of the competition,” added García-Cosío Carmena.

“The space industry is incredibly competitive, so we often find that manufacturers are more willing to take calculated risks to balance cost, performance and speed. While it’s clear that AM offers the speed and design flexibility required in these applications, it is a costly technology, so manufacturers should consider how to find the best balance. For example, when approaching a new product, clearly, it’s vital to comply with all the requirements, although it is necessary to understand where they come from and if they can be reformulated whilst still maintaining performance,” continued García-Cosío Carmena.

Subtractive or additive

Metal AM has been a useful tool in the production of components with complex geometries, giving manufacturers such as CiTD the ability to design and manufacture parts with better performance when compared with traditional manufacturing methods. However, it’s important to understand that AM technologies complement traditional methods, not replace them. Subtractive and additive manufacturing offer different benefits and drawbacks and the most robust approach for space applications is to use a combination of the two when developing components — merging the accuracy and reliability of traditional manufacturing with design freedom of AM.

“The most successful use cases are those where the AM process and material properties provide added value,” explained Hernández Álvarez. “Traditional manufacturing has decades of heritage, so there are always applications where machining, injection molding or other methods may be preferable. However, changes in regulations, pressure from lead times and the need for mass reduction and lightweighting means that AM can be a valuable alternative, despite the cost.

“Determining the best manufacturing method requires engineers to review the part and its performance. If AM can improve part performance, such as delivering better conductivity or strength to weight ratio, it will add value to the final component. Parts such as heat exchangers and radio frequency (RF) antennas are good examples of where to use AM, because engineers can optimise the geometry to improve efficiency. Alternatively, when developing simple yet core components, such as flat plates, additive adds no value to its properties, so it will always be better to use traditional machining,” continued Hernández Álvarez.

The JUICE mission

To explore Jupiter’s complex environment, as well as its three large ocean-bearing moons — Ganymede, Callisto and Europa — the ESA launched the JUICE mission. Working in collaboration with AIRBUS Defence and Space, CATEC and CiTD, the ESA set an objective to optimise the structure of the explorer and reduce its weight as much as possible.

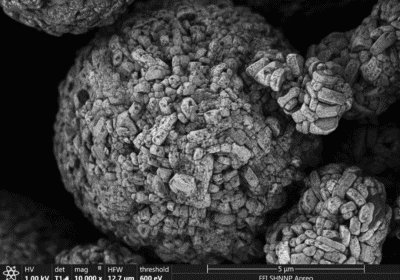

“Our team helped produce eleven additively manufactured secondary structure brackets for the JUICE project, using AM technology to deliver lightweight, high-performance parts,” continued García-Cosío Carmena. “By using high strength aluminium alloys, optimising component design and collaborating with the other AM specialists on the project, we were able to produce brackets that were 50 per cent lighter than traditional ones.

The project was also a unique experience for Renishaw, as it marked the first time that any product featuring parts manufactured on a Renishaw RenAM 500 system would travel to Jupiter and its satellites. The JUICE mission launched in April 2023 and is due arrive on Jupiter in July 2031, where it will spend three years making detailed observations of the planet and its satellites.

What’s next?

As AM technology advances, improved productivity will help lower cost per part and open the technology to new applications. In terms of space applications, any development should improve the robustness of the process and ensure that parts can meet the tight tolerances expected in the sector.

“Part inspection and verification will be integral to the future of AM in space applications,” continued Hernández Álvarez. “Manufacturers must currently test all iterations of a part, including prototypes and final units, at the end of production, using CT scanning to ensure there are no internal defects. Currently, this process can be costly, as manufacturers may only be able to see defects after a build is complete, causing manufacturers to scrap the part. So, to improve the robustness of the process, AM users are considering how to reduce the cost of verification and control measures. As a result, process monitoring tools and artificial intelligence will be key to the future of AM in space applications.”

As companies compete to capitalise on the burgeoning opportunities in space exploration, the convergence of subtractive and additive manufacturing methods presents manufacturers with the design freedom to develop unique components as well as the accuracy to meet stringent demands. By focusing on precision, performance and cost-effectiveness, manufacturers can expect AM to help develop groundbreaking advancements in future space applications.

For further information on the benefit of Renishaw AM systems in space applications, visit www.renishaw.com/en/metal-3d-printing.