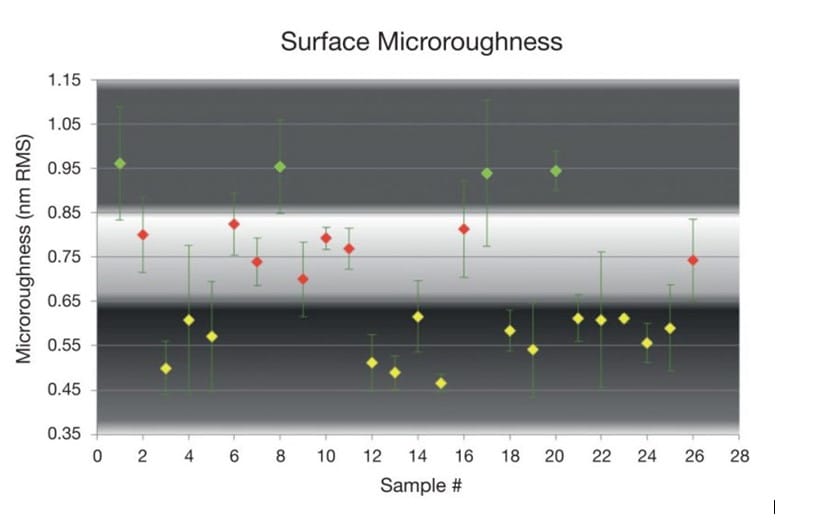

Optical Surfaces Ltd. has pioneered a pitch-polishing technique, that produces consistently low surface microroughness on off-axis parabolic mirrors used as key focusing elements for high power laser experiments.

Microroughness is a component of surface texture, it can be determined by looking at deviations from the mean line profile of a mirror surface. Several renowned plasma physics groups have reported that as microroughness becomes more pronounced, it causes effects akin to mild scattering which limit the focusing performance of off-axis parabolic mirrors. Using their proprietary pitch polishing technique – Optical Surfaces has shown that microroughness can be controlled during the manufacturing process of off-axis parabolic mirrors at consistently below 1nm RMS. This technique is enabling production of a new generation of ultra smooth mirrors thereby helping advance the frontiers of high-power laser physics.

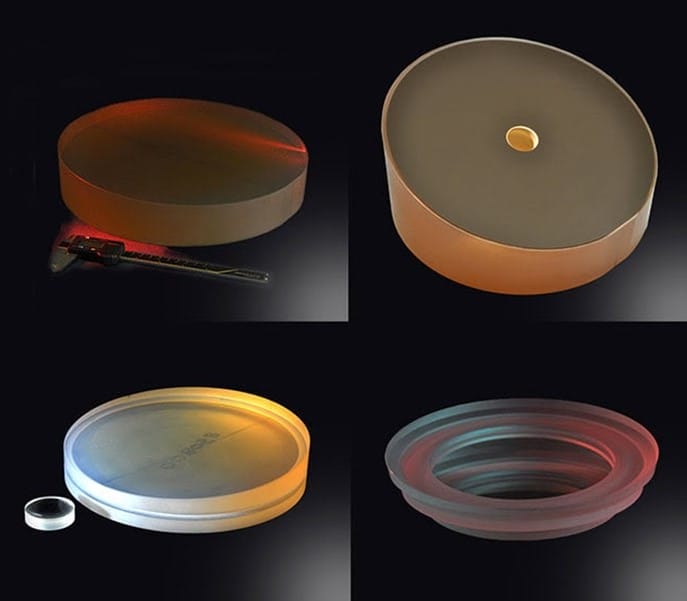

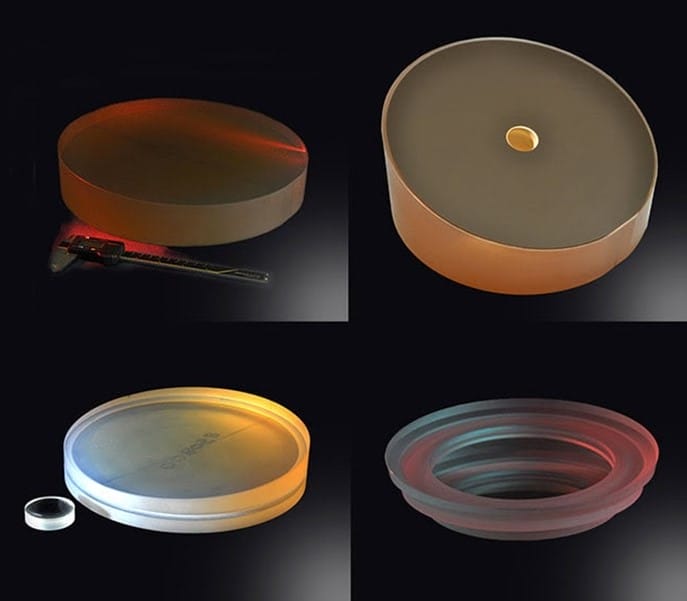

Off-axis parabolic mirrors combine the achromatic and diffraction limited imaging properties of a parabolic mirror with the ability to deviate the light path off-axis, which is useful for most imaging systems. Off-axis parabola offer the ability to focus collimated light without introducing spherical aberration. Additionally, unlike a centred parabolic mirror, an off-axis parabolic mirror advantageously allows more interactive space around the focal point without disrupting the beam. These mirrors are especially suitable for broadband or multiple wavelength high power laser applications.

Using proprietary production techniques, and benefiting from a uniquely stable manufacturing environment, Optical Surfaces highly experienced and skilled engineering team are world renowned for producing fast focusing OAP mirrors with unmatched surface accuracy, surface microroughness and surface slope errors.

In recent years – Optical Surfaces have been selected by world leading high power laser research groups including AWE, ELI, LULI and CLF Rutherford as well as a growing number of academic centres of excellence to provide key off-axis parabolic mirrors and other related optics for a range of demanding high-power laser applications.

For further information on off-axis parabolic mirrors with exceptional low microroughness for high-power laser experiments please contact Optical Surfaces Ltd. on +44-208-668-6126 / sales@optisurf.com. To download a copy of the study ‘How microroughness impacts optical performance’ please visit http://www.optisurf.com/index.php/news/technical-tips/

Optical Surfaces Ltd has been producing high precision optical components and systems for nearly 60 years. The company’s ISO 9001-2015 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant, and vibration is practically non-existent. With such stable conditions testing, particularly with long path lengths, becomes quantifiable and reliable.