Innovative post processing paves the way for mass production in metal 3D printing

The AutoSmooth project, launched last year by Headmade Materials, AM Solutions – 3D post processing technology, and Neue Materialien Bayreuth, is showing its first promising results with regard to highly efficient processing times and significantly improved surface quality. By 2025, a system will be introduced to the market that will revolutionize the surface treatment of ColdMetalFusion (CMF) parts. With this, AM Solutions provides the “missing link” to make CMF technology – and thus metal 3D printing – suitable for mass production.

The AutoSmooth project, initiated last year by Headmade Materials GmbH in cooperation with AM Solutions – 3D post processing technology and Neue Materialien Bayreuth GmbH, focuses on CMF technology and has made impressive progress. Since the project began, the partners have worked intensively to significantly advance the development of a fully automated process chain for unpacking, depowdering, and surface treatment of ColdMetalFusion parts. The initial results are very promising, bringing industrial implementation within reach.

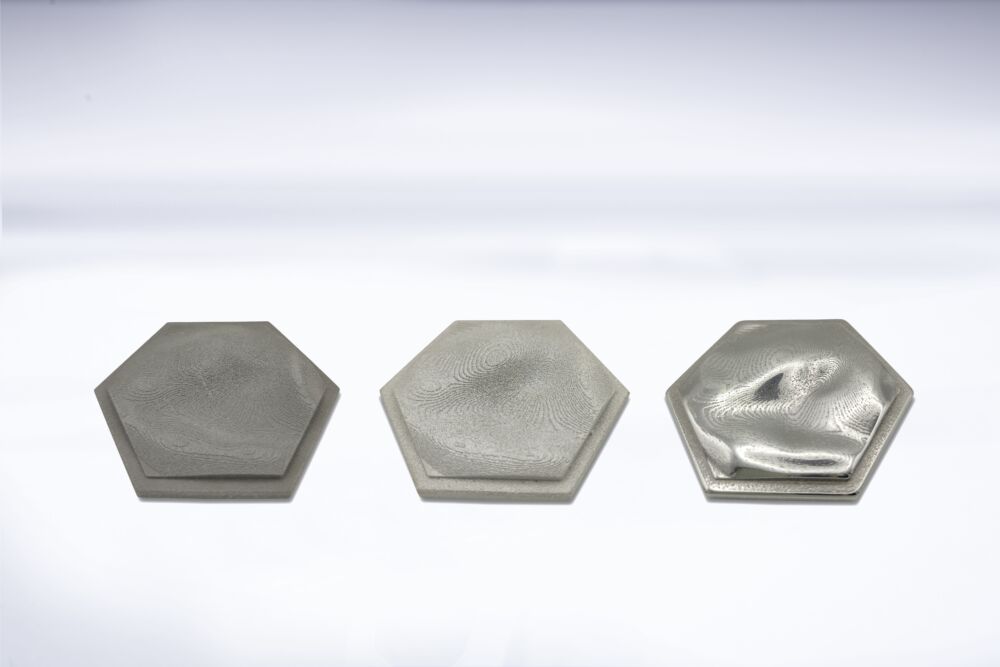

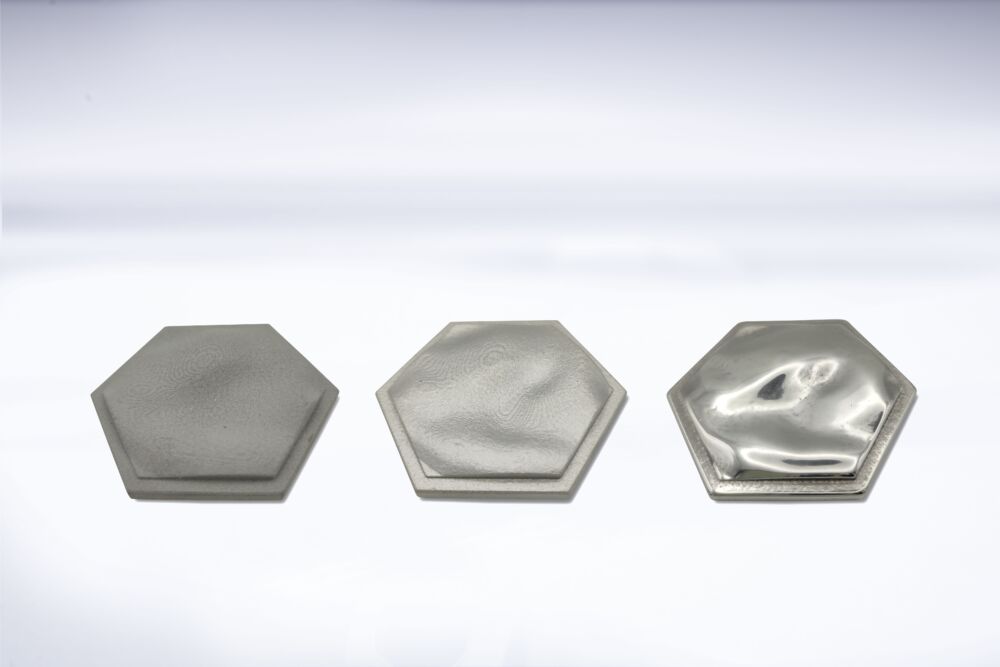

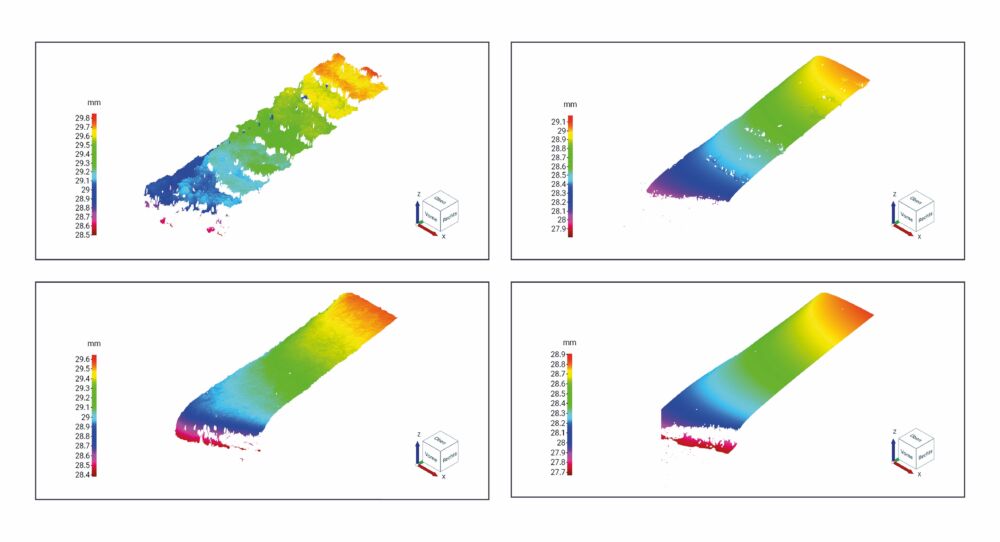

Fast and efficient green part processing ensures excellent surface quality in the final part

AM Solutions – 3D post processing technology has contributed all its expertise in surface treatment to the development. The result is a system that will significantly improve green part processing. An innovative shot blasting process ensures that the surfaces of the parts are finely depowdered and smoothed in a single operation. Staircase effects are effectively removed, and the surface quality is already so high that in most applications there is no need for an additional, lengthy finishing process after sintering. This saves an enormous amount of time. For example, the process of depowdering and smoothing takes only a few minutes, whereas conventional post processing methods can take several hours.

Integrated 2-in-1 solution with an additional powder recovery system

As part of the AutoSmooth project, AM Solutions once again relies on its proven 2-in-1 principle, combining the two process steps of depowdering and smoothing in just one machine. Additionally, the powder is recovered thanks to an advanced system and can be reused, ultimately resulting in significant cost reductions and conservation of valuable resources. A specialized part clamping solution also ensures the careful handling of sensitive green parts during the process.

CMF technology offers many advantages

ColdMetalFusion technology already allows users to produce high-quality metal parts in series through cost-effective additive manufacturing. The main advantage is that a standard and therefore inexpensive powder bed-based polymer printer is sufficient for printing, making the process an interesting drop-in technology for many companies. The parts do not require support structures, which would need to be laboriously removed after printing. Compared to other binder-based processes, CMF technology also excels, as the green parts are significantly more stable, offering greater process reliability.

“If we now provide the ‘missing link’ in post processing with our new development, CMF technology will take a huge leap forward,” says Dr. Till Merkel, Division Manager Technology at Rösler Oberflächentechnik GmbH. “For the industry, this paves the way for cost-efficient, automated processes that will fully unlock the potential of additive mass production for metal parts and significantly reduce unit costs.” The new system from AM Solutions is expected to be available on the market by 2025.

Insights at the trade show

At the Formnext trade show in November, AM Solutions will offer industry professionals insights into the progress of the AutoSmooth project. The company can be found in Hall 11.1, Booth E41. The partners Headmade Materials will be located in Hall 11.1, Booth C51, and Neue Materialien Bayreuth in Hall 12.1, Booth C71.

Rösler Oberflächentechnik GmbH / AM Solutions

For over 80 years, the privately owned Rösler Oberflächentechnik GmbH has been actively engaged in the field of surface preparation and surface finishing. As global market leader, we offer a comprehensive portfolio of equipment, consumables and services around the mass finishing and shot blasting technologies for a wide spectrum of different industries. Our range of about 15,000 consumables, developed in our Customer Experience Centers and laboratories located all over the world, specifically serves our customers for resolving their individual finishing needs. Under the brand name AM Solutions, we offer numerous equipment solutions and services in the area of additive manufacturing/3D printing. Last-but-not-least, as our central training center the Rösler Academy offers practical, hands-on seminars to the subjects mass finishing, shot blasting and additive manufacturing. The Rösler group has a global network of 15 locations and approx. 150 sales agents.

For more information, please visit: www.solutions-for-am.com