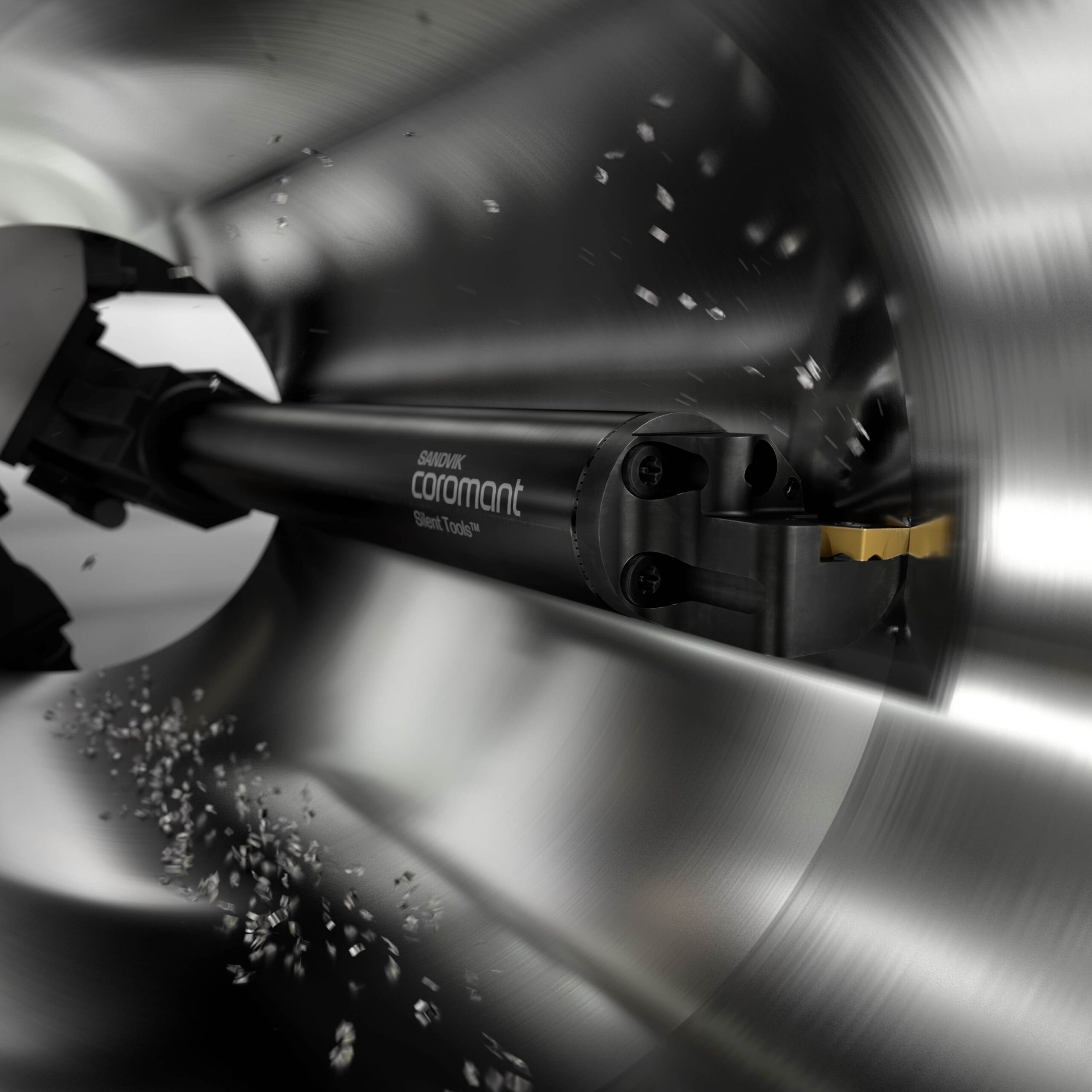

Smooth performance without vibrations

Cutting tools specialist Sandvik Coromant has upgraded the damping mechanism for Silent Tools™ turning adaptors for an even more consistent performance and improved surface finish during internal turning operations at long overhangs. The new adaptors integrate seamlessly with the new generation of CoroTurn® SL cutting heads, which feature side-oriented internal through coolant.

With close to 50 years of experience in preventing vibration, tool-holding system Silent Tools™ from Sandvik Coromant has aided machining at long overhangs by effectively damping vibrations. Now 33 cylindrical and Coromant Capto® items from the turning adaptor range (diameters 16–25 mm and ⅝–1 inch) have been improved and equipped with an overhauled and refined damping mechanism.

“The damping mechanism has been substantially upgraded compared to the former generation of Silent Tools™ turning adaptors”, says Åke Axner, Global Product Manager – Machine Integration at Sandvik Coromant. “The damper body, previously requiring manual fine-tuning, is now calibrated and assembled by a machine. This automation results in a highly precise and predictable frequency area, perfectly matched to each adaptor’s intended overhang and application. This means that Silent Tools™ turning adaptors are more efficient at countering vibration forces at long overhangs than ever before.”

Thanks to the upgrade, Silent Tools™ turning adaptors will ensure improved consistency and machining repeatability over all available length-to-diameter ratios, for a more reliable and high-performing product.

Silent Tools™ and CoroTurn® SL — the perfect combination

To further ensure optimal performance and boost productivity, a new generation of CoroTurn® SL cutting heads for small diameters (sizes 16 and 20) featuring side-oriented internal through coolant has been developed to integrate with the upgraded turning adaptors.

“The new CoroTurn® SL cutting heads benefit from Silent Tools™ technology, which provides improved stability performance,” explains Daniel Conessa, Global Product Manager — Turning at Sandvik Coromant. “These two products work together to enhance component quality, increase machining process stability, reduce scrap and unnecessary rework, as well as minimize unplanned machine stops. Furthermore, downtime will be reduced due to better chip control, which is one of the main issues when boring long overhangs in small diameters.”

The upgraded Silent Tools™ turning adaptors in sizes 16 and 20 mm (⅝ and ¾ inch) seamlessly integrate with the new generation of CoroTurn® SL cutting heads in sizes 16 and 20, which feature side-oriented internal through coolant. Additionally, Silent Tools™ turning adaptors in size 25 mm (1 inch) are a perfect fit for existing CoroTurn® SL cutting heads in size 25 with high precision coolant. When combined with the corresponding adaptors, these cutting heads provide all the same benefits mentioned above.

“If our customers need a vibration-free workpiece and top-quality results, while maintaining the tight tolerances required, CoroTurn® SL heads combined with Silent Tools™ deliver precisely that. Additionally, this solution will also reduce their operation costs and maximize productivity”, concludes Conessa.