Preventing condensation for worldleading electron cryo-microscopy

Preventing condensation for worldleading electron cryo-microscopy

4

At the forefront of digital marketing, Engineering Update strives to bring the latest in industrial engineering in a format that provides the best usability and ease of use for our readers.

Publication Director

Jodie Little

01843 595818

jodie@jetdigitalmedia.co.uk

Editorial Assistant

Laura Sharpe

01843 448 443

laura@engineering-update.co.uk

Editorial Assistant

Leigh Little

01843 448 443

leigh@engineering-update.co.uk

Publishing House

Jet Digital Media Ltd, Suite 1 & 2 Spratling Court Offices, Spratling Street, Manston, Kent CT12 5AN

7

12

34

STEM:

26

Step

NIS

www.engineering-update.co.uk

Preventing condensation for worldleading electron cryo-microscopy

SEEPEX to showcase progressive cavity pumps at Foodex

Preventing condensation for worldleading electron cryo-microscopy

SEEPEX to showcase progressive cavity pumps at Foodex

For years, Munters, global leaders in indoor climate solutions, has supplied and maintained dehumidifiers used for critical research at Medical Research Council Laboratory of Molecular Biology (MRC LMB).

The MRC LMB is a world-class laboratory that is tackling major problems in human health and disease. Over the years, they have attracted 12 nobel prizes, as well as dozens of scientific awards and honours in molecular biology.

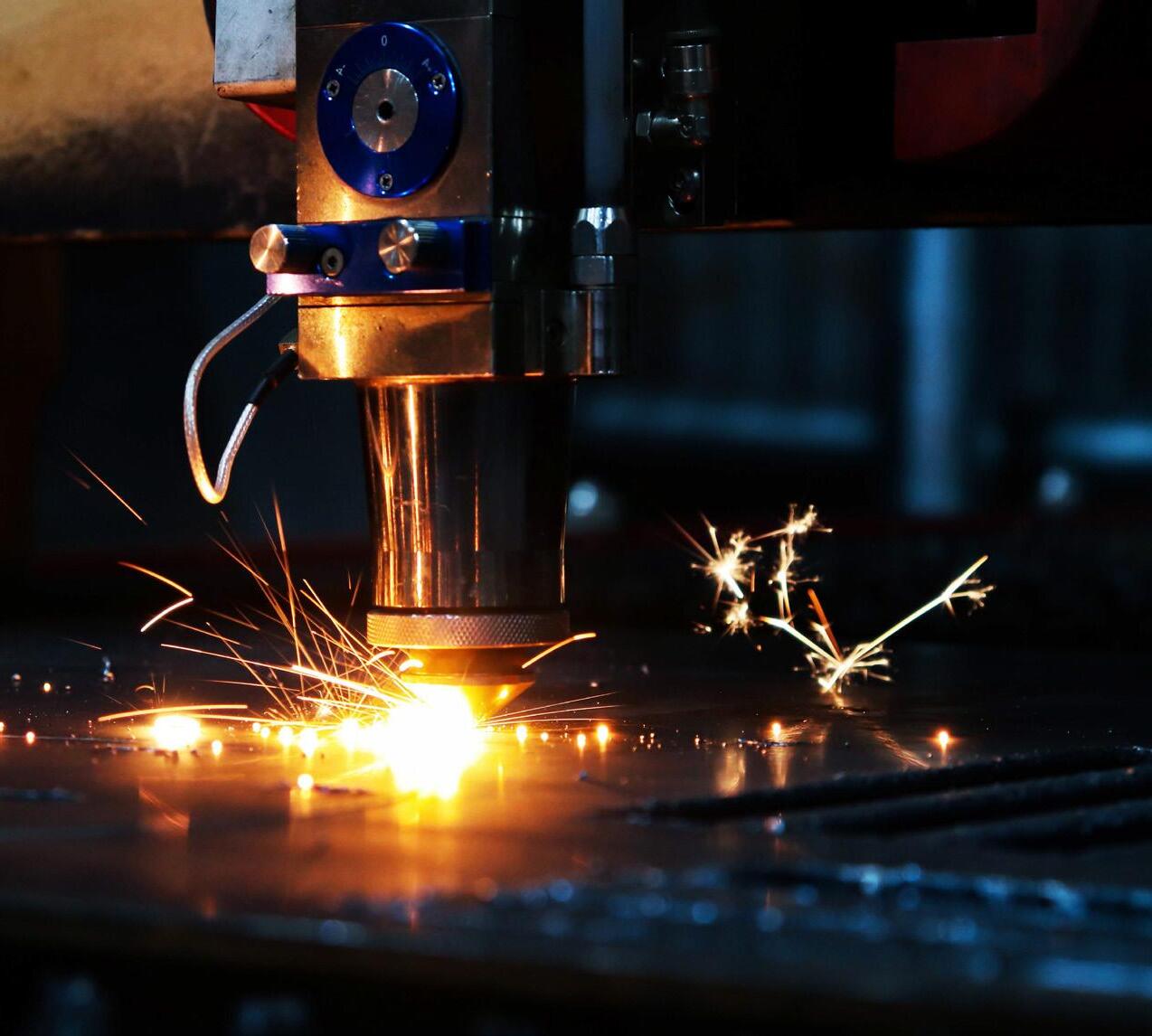

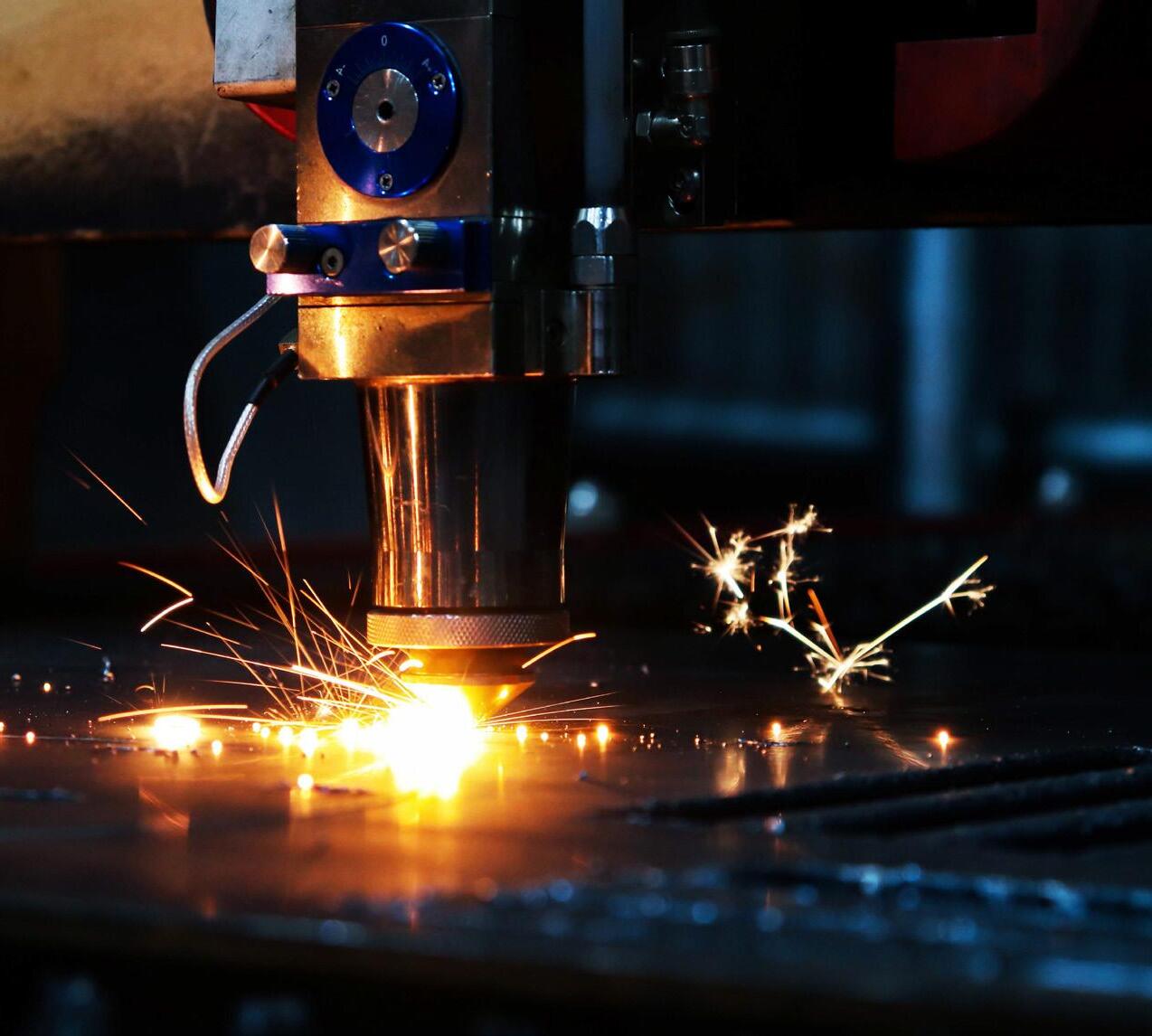

Within the MRC LMB lies several cryolaboratories, along with a world leading, electron cryo-microscope - a multimillion pound investment that is used for carrying out critical research into human health and disease.

For more than a decade, Munters has supplied and maintained dehumidifiers that are essential for the effective operation of this microscope.

The electron cryo-microscope is an incredible invention. Research specimens are submerged into liquid ethane at -193°C. This process freezes them so quickly that it creates a glass, or water glass, which enhances the clarity of the molecules within the specimens.

“In this instance, water is both the friend and the enemy” says Dr Chris Russo, MRC LMB group leader. “When submerging research samples into the ethane at liquid nitrogen temperatures, it is absolutely critical that other moisture is minimised, otherwise the sample could be ruined.”

And it’s for this reason that dehumidification is so crucial. “Without dehumidification, even the slightest amount of excess moisture will cause ice to build on the specimens. If the resolution is poor, we won’t get the image and won’t solve what we need to”.

The microscope itself is also susceptible to moisture damage. Strong electrodes and iron magnets can corrode and decay if relative humidity is not effectively controlled within the cryo-laboratories.

Munters has supplied several ML plus temperature and humidity control systems to maintain a temperature of 20°C at 20% relative humidity. Unusually, the plant room where the dehumidifiers are installed is situated above the laboratories on a floating plant room floor to prevent vibration. The temperature and humidity control systems were uniquely designed so that they could be broken down into modules, enabling them to fit through small gaps during installation.

Dr Stephen Holmes, head of estates and capital projects at the MRC LMB states. “Munters really understands our needs. The dehumidifiers work extremely well and are very robust. For over 10 years, our relationship has continued to grow. We have had great continuity from the service team.”

The MRC LMB is committed to their targets of achieving net zero by 2040, and halving carbon emissions by 2050, and Munters is committed to ensuring dehumidification supports this journey.

Advantages: Prevent condensation causing damage to research samples and multi-million pound electron cryo-microscope.

Deliver bespoke temperature and humidity control systems in modular format to enable installation where space and access is restricted

For the full story, visit munters.com

Investing valuable CAPEX into untested High Value Equipment carries certain risks. Will the equipment work? Is it the right solution? Will it waste company funds? These questions regularly stop CAPEX purchases in their tracks.

Filtration specialists Axium Process have answered these questions with a membrane separation rental service that swiftly bypasses traditional concerns. Axium’s new service is a valuable resource for fast or temporary filtration solutions that normally require deep research and risky commitment to large capital investment.

Suitable for many liquid processing applications, Axium’s UF2Go and RO2Go crossflow systems are rapid filtration solutions. The UF2Go and RO2Go meet industrial scale demand for most types of liquid processing requirements and can fulfil high-priority needs from their range of universal membrane filtration options.

“The UF2Go and RO2Go crossflow systems provide a solution for urgent filtration needs,” says Derek Davies, Business Development Director at Axium Process. “Available through a rental model typically using OPEX, they bypass usual CAPEX restrictions but allow observation of long-term trends - ideal for situations where a permanent installation may be required in future.”

Quick to install and easy to use, the systems are compatible in many different industries, including pharmaceutical, food, beverage, dairy and water recycling.

From removal of suspended solids and organic impurities to wastewater recovery, high-value protein extraction

and more, the concept is built on tried-and-tested technology used by leading brands.

“Both systems are easy to deploy with minimal operator intervention and can be up and running in a matter of hours,” says Derek. “During installation and commissioning, full operator training will be conducted by our technical engineers.”

“We understand the need for businesses to find simple, cost-effective solutions for everyday problems and are excited to offer this level of flexibility and support to our customers.”

Axium Process is a leading membrane filtration system manufacturer, specialising in Microfiltration, Ultrafiltration, Nanofiltration and Reverse Osmosis technology.

In food processing, SEEPEX pumps are ideal for transferring thin to highly viscous, sticky products and those containing soft solids. Their low shear action preserves the integrity of shear-sensitive products such as yoghurt, cream, yeast, ice cream and sauces. Hence, removing the need for costly additives to restore product texture and appearance.

SEEPEX’s EHEDG pumps meet the highest hygiene standards for the food and beverage industries. Their internal design guarantees residue-free cleaning with CIP/ SIP and the low shear pump action ensures the highest product quality. For highly viscous to nonflowable products, we also offer our open hopper pump ranges in hygienic design.

SEEPEX has created a pumping system for handling difficult food waste - such as fruit including stones, vegetables, poultry and ready meal packaging. This integrated maceration and pumping technology enables hygienic waste removal through enclosed pipework from high-care to low-risk areas. With

this solution, waste volume can be reduced by up to 60% with significant transport cost savings.

Our Smart Air Injection (SAI) technology is used in breweries and distilleries to remove spent grain, draff and hops. This system uses a progressive cavity pump and pneumatic dense-phase conveying to boost efficiency and reduce energy use. SAI can convey products with 1540% dry solids in 20-30 m long plugs over distances of up to 1,000 metres using controlled air pulses.

of ingredients, such as colours and flavours, to maintain high-quality products and control costs. SEEPEX’s Digital Solutions can restore pump performance and efficiency, and increase uptime with predictive and planned maintenance.

“In few other sectors are the demands on pump technology higher than in the food and beverage industry. Our pumps are utilised widely for food waste processing but also meet the most stringent hygiene regulations for use in production“, explains Damian Clifford, Commercial Lead for SEEPEX UK.

Trust

THE Guardtech Group Service Department provide a wide range of Service & Maintenance programmes as part of their Cleanroom Service Plan.

Clients can rest assured, safe in the knowledge that by entrusting the Planned Preventative Maintenance (PPM) of their process rooms, plant, utilities and devices to Guardtech, the risk of a major fault developing diminishes significantly.

Guardtech clients tend to take on either a one, three or five-year Cleanroom Service Plan with a minimum of two visits per year from engineers as standard, but the Group can support you with one-off visits, as well as bi-monthly, monthly, weekly or even daily programmes for Decontamination.

From Commissioning newbuild cleanrooms to Service, Maintenance, Testing, Validation and Decontamination of existing controlled

environments, the Guardtech Group Service Department support ongoing compliance in all cGMP & ISO14644 classified cleanrooms, ensuring facilities are audit-ready and compliant with regulatory bodies.

A thorough Testing programme includes Filter Integrity and Separative Devices –such as biosafety cabinets and laminar flow benches – as well as Performance Testing, including Temperature, Humidity and Lux levels.

Validation features measurements for Air Velocity, Volumetric Flow Rate and Room Differential Pressure, as well as Particle Counting – all in accordance with ISO 14644-1.

The Service & Maintenance remit is significantly wide – from HVAC, compressor and generator repairs and upgrades to filter replacements, gauge calibration and environmental monitoring (EMS) and Building Management System (BMS) Servicing.

Resolve Optics is a leading supplier of application optimised fi xed focus and zoom lenses designed to enable high performance measurements in the ultraviolet (UV) waveband (200-400 nanometres).

To provide inspectors with an effective tool for non-intrusive verification of spent nuclear fuel, a global leader in nuclear safeguards technology asked Resolve Optics to design a wavelength corrected UV Zoom lens to enable its Digital Cerenkov Viewing Device to view a nuclear fuel assembly situated 13 metres away from the lens and through 10 metres of water. Spent nuclear fuel emits a faint UV (Cerenkov) light when gamma rays from fuel assemblies interact with electrons in the cooling pond water.

To meet the challenges of this demanding application – Resolve Optics designed the UV zoom lens to optimally operate from 10 to 55ºC. By incorporating a telescopic focus in the design, the novel lens can image objects from 3m to infinity. Miniature motors on the lens allow accurate remote setting of both zoom and focus functions. A filter slide was also incorporated in the design enabling the lens to be switched between UV (270 to 350 nm) and visible (400 to 700 nm) without the need for refocusing. The lens achieves high image resolution with low distortion throughout the zoom range without refocusing. A lockable C mount ensures the lens cannot come loose during operation.

The Digital Cerenkov Viewing Device equipped with UV Zoom lens provides a highly effective system that captures the Cerenkov image of spent nuclear fuel for analysis and comparison.

For further information on application optimised UV lenses please visit https://www.resolveoptics.com/uv-ir-and-swir-lenses/ or contact Resolve Optics on +44-1494-777100 / sales@resolveoptics.com

In processing plants that require the highest levels of hygiene, sterility and leak-tightness, excessive overpressure or vacuum can occur due to a wide variety of causes. In such cases, rupture discs protect both vessels and pipelines from deformation and further damage. Above all, they protect the lives of the employees who work in these plants. The primary goal here is to provide optimum protection for these systems, taking into account technical and economic aspects, while at the same time minimising system downtime.

Excessive overpressure can occur in almost all production areas and processes in the pharmaceutical industry. If the pressure exceeds or falls below the limits defined for the process, serious damage can occur to the respective plant components. Possible consequences include production stoppages and significant economic damage. Therefore, in situations where the pressure exceeds or undershoots the permissible operating range, a reliable and fast-acting pressure-relief device is essential.

Many operators in the pharmaceutical industry already use REMBE high-performance rupture discs in their processing plants – because the advantages of these pressure-relief devices ensure permanently safe operation:

• Thanks to their leak-tightness, our rupture discs prevent the escape of process media

• The complete cross-sectional release of the burst element provides immediate pressure relief for the system

• REMBE rupture discs have a response time of mere milliseconds

In order to customise the design of our rupture discs for each customer, numerous factors must be considered ahead of time. Reliable and economical rupture discs are not standardised products. Instead, they are individually adapted to the respective process conditions, designed accordingly and then manufactured specifically for the customer’s applications. Numerous parameters are taken into account to ensure optimal performance.

These parameters include:

• the medium in the system to be protected (liquid, sticky, gaseous, etc.)

• the operating temperature for which the rupture disc is designed (room or max. operating temperature).

• the required resistance to vacuum

• the mounting method (tri-clamp or holder system)

• the required pressure-relief area

• and many more

As well as pipelines, in the pharmaceutical industry there are additional plant elements, such as reactors, filling plants and tank farms, which must be protected against overpressure and vacuum and equipped with safety-related components. However, protection against impermissible pressures is not the only consideration in the pharmaceutical industry. Leak-tightness and the sterility of the respective components are also critical factors. Last but not least, reducing downtime is a key requirement with regard to the use of rupture discs.

In order to keep costly system downtime to a minimum, it is essential that the rupture discs can be installed quickly and easily. Our rupture discs can be installed using a tri-clamp connection, which provides a sterile and extremely reliable seal. When REMBE developed the KUB clean reverse acting buckling pin

rupture disc, one of our goals was to meet the requirements for sensitive processes in the pharmaceutical industry, such as leak tightness and sterility. This reverse acting rupture disc is installed with the bulge facing the process and allows the operator to achieve an operating pressure ratio of up to 98%. Overall, this reverse acting rupture disc is an extremely durable and robust solution that virtually eliminates the risk of premature bursting.

The unique design of the KUB clean is based on a two-layer structure, whereby the side facing the process has a completely smooth surface, which prevents product build-up. The integrated seal ensures the required degree of tightness for the rupture disc. It meets all hygienic design requirements (FDA and USP Class VI compliant) and is suitable for both CIP and SIP. In addition, the seals can be replaced; the rupture disc can thus be reused immediately after an inspection or cleaning.

Each KUB can be optionally equipped with a signalling function. As soon as an excessive overpressure is reached and the rupture disc has burst, signalling becomes a very important safety factor in sensitive production facilities by ensuring that the rupture disc is subject to permanent monitoring.

From 9 - 11 May 2023, the rail industry will gather for Railtex 2023 at the NEC in Birmingham. The show provides a unique opportunity to meet with national and international players and thought leaders, all looking to enhance the passenger experience, freight logistics and the overall efficiency of railway operations. Participants can expect live demonstrations of new machines and systems, technical inperson discussions and a rich supporting programme packed with keynote speakers from leading industry names. Railtex will once again reinforce its role as the central marketplace for the industry to come together and discuss both challenges and opportunities in the light of current developments within the rail industry.

Keeping the current rail market in mind, it is particularly important to focus on crucial topics such as decarbonisation and investments to create a more sustainable rail industry, the digitalisation of rail transport, as well as the passenger experience. It is essential to not only address and mirror these topics, but to also come together to find common solutions and shape a successful future for the rail industry. This is precisely what Railtex facilitates. “Railtex 2023 is the place to be with all key players gathered in one place. We are glad to have the great support from our main show partner RIA – the Railway Industry Association, as well as our show partners, Rail Forum, Railway Benefit Fund, the CPD Certification Services, our media partners, and many more.” states Olaf Freier, the Transport Portfolio Director.

Images ©2023 Mack-Brooks Exhibitions Ltd - Part of RX, St Albans, UK

The visitor registration is now open, and free tickets can be ordered online ahead of the show. During the exhibition, tickets can be purchased on-site or via the online ticket shop. For smooth entry, visitors are advised to print out their e-ticket or download their mobile ticket prior to the show.

Show opening hours are from 10:00 AM to 17:00 PM on Tuesday, 9th May 2023, and Wednesday, 10th May 2023, and from 10:00 AM to 16:00 PM on Thursday, 11th May 2023.

More information at: www.railtex.co.uk

Read the full article here

As engineering managers come under pressure to meet demanding schedules, often with fewer skilled hands and tighter budgets, the benefits of professional tool storage and management become stronger than ever.

Snap-on Industrial’s Level 5™ automated total asset management system brings order to any workplace, enabling engineers and technicians to know exactly where to find every tool they need, when they need it, saving time and easing stress.

How useful would it be if all valuable tools could be tracked from one central point? Snap-on’s Level 5™ system makes that possible. It provides complete reports on everything

managers or supervisors need to keep an eye on.

And then there’s FOD. The threat of foreign object damage is a real and present danger in many engineering workplaces. Using Snap-on Level 5™ minimises the risk of human error, as automated tool control constantly tracks every tool and detects which tools have been removed or returned, ensuring greater protection against FOD.

Engineered to track individual tools by user, without bar codes, scanners, RFID tags or other add-ons, the system works at the speed its users demand. Other systems require additional steps to scan or log activity. The Snapon system does this automatically so users save time and don’t have to depend on other steps to ensure accurate results.

Snap-on’s Level 5™ ATC boxes are network ready, using either Ethernet or wireless connection. That enables users to review activity at all Level 5 boxes in their location from one central computer, avoiding the time consuming need to inspect each box.

Major benefits of the system include:

• No individual tool scanning required;

• No RFID tags to install or replace;

• No limitations on tool size: from ¼” screwdriver bit upwards;

• Intuitive interface, with an easy to use touchscreen

• Audible voice announcement of tool removal and replacement

• Automatic locking for maximum security

• Errors announced and displayed to indicate incorrect tool position or advise when a drawer is not closed.

Says Richard Packham, Director UK & Europe for Snap-on Industrial: “Snapon’s automated system takes asset management to an entirely new level. The ability to monitor several boxes from one central computer offers a huge advantage to engineering managers.”

For technical information visit: www.snapon-industrial.co.uk; call (01536) 413904 or e-mail:

ukindustrialmarketing@snapon.com

Wolf Safety have introduced a powerful new range of ATEX certified LED installed lighting, designed for permanent use in potentially explosive atmospheres.

The world’s leading manufacturer of portable and temporary ATEX and IECEx certified hazardous area safety lighting, Wolf have been keeping people safe for more than 110 years.

The company’s designers and production engineers have now brought their vast knowledge and expertise to bear on a new range of highly effective LED installed lighting, which is safe to use in Zones 1 and 21 hazardous areas.

The range includes:

• Linear luminaires featuring the new, revolutionary Directional Linear Optics (DLO) or standard Forward Facing Array LED configurations (with battery back-up emergency versions also available);

• Floodlights with a market leading maximum light output of up to 25,932 lumens;

• Bulkhead lighting, also featuring DLO (with battery back-up emergency versions also available);

• High bay lighting.

DLO directs light exactly where it’s needed and is ideal for use in specific, close-up workspaces, reducing glare to avoid people being ‘blinded’ by the emitted light, while its excellent colour definition facilitates safety critical hazardous area tasks.

Forward Facing Array (FFA) technology can be preferable for safely illuminating large hazardous areas which need wide, even and bright light coverage, where lights are mounted away from people or at heights where glare and intensity can’t have an adverse effect on the working environment.

Says Miles Jackson, Wolf Safety’s Sales and Marketing Director:

“We know that users of Wolf products trust us to keep them safe, especially when they need to work in highly volatile atmospheres and other hazardous workplaces.

“All the values people expect from Wolf - and are seen in our portable and temporary lighting ranges - can now be found in this new installed lighting range, which we are proud to introduce.”

For detailed technical information visit: www.wolfsafety.com

accurate

Storage Tanks

The Cygnus 1 Ex Ultrasonic Thickness Gauge is a rugged, intrinsically safe instrument designed for taking thickness measurements in Zone 0 explosive atmospheres.

• Certified to ATEX, IECEx, UKEX for Zone 0 and NRTL for Class 1, Division 1

• 3 measuring modes for corrosion, various materials and through-coat measurements

• Manual Measurement Mode allows gates and gain to be configured to suit your application

• Live A-Scans and B-scan for visual verification

• 4 quick function keys for easy control

• Comprehensive data logging for easy reporting

measurement in cygnus-instruments.com • sales@cygnus-instruments.com

Precision flow measurement is a critical tool for the Pharmaceutical and Medical industries, where processes require the precise control of liquid flow rates. Titan’s NSF-approved 800-series turbine flow meters are ideally suited for applications where both food-grade hygiene and precision flow measurement are required, such as those seen in dispensing and accurate batch delivery systems for ingestible pharmaceutical products and additives.

Titan’s NSFapproved 800-series flowmeters, certified under NSF/ANSI 169 as equipment for food products, are designed for precise metering of low viscosity liquids - water, water-soluble chemicals, drug coatings for example. These mini turbine sensors provide a low-cost dispensing solution giving reliable, high performance over 6 flow ranges from 0.05 to 15 L/min.

The 800-series flow measuring devices have totally non-metallic NSF-approved wetted components that ensure safe dispensing of ingestible materials. The flow device’s body and turbine are moulded from inert PVDF to ensure there is no contamination to any liquid passing through it. The bearings within the Titan mini turbine flow sensors are made of sapphire giving long life and reliability.

As an experienced OEM supplier, Titan develop customised flow meters for specific applications within the pharmaceutical and medical industries “Accurate dosing of drugs in a medical environment, such as intravenous drug administration, can be controlled and monitored using flowmeters,” says Neil Hannay, Senior R&D Engineer at Titan Enterprises. “Titan have done some extensive pioneering work with a USA medical company to produce a disposable ultrasonic flowmeter that would measure the volume of liquid manually injected into a patient.”

The NSF-Approved 800-Series flow meters have also proved a valuable component within Paxman’s innovative liquid-based cooling system. The scalp cooling technology utilises Titan’s mini turbine flowmeters to monitor the rate of coolant flow around the patented cooling cap during chemotherapy treatment.

To discuss an optimised flow measurement device for your OEM application please contact Titan Enterprises on +44 (0)1935 812790 or email sales@flowmeters.co.uk Or visit our website for further information.

SICK has expanded its proven, non-contact magnetostrictive linear encoder portfolio with the launch of a versatile product family for wide-ranging industrial applications. The DAX® linear encoders precisely determine the absolute position of pistons in hydraulic cylinders, as well as reliably monitoring linear motion in many common industrial machines.

The SICK DAX linear encoders have been designed with a flexible product concept to make specification quick and easy for both new and existing users, using a unique online configuration tool with options for additional customisation. They therefore offer a timesaving way for cylinder manufacturers, OEMS and end-users to access a reliable source of supply.

The DAX encoder family has industryappropriate measuring ranges for countless applications as diverse as packaging machines, wind, hydro and solar plants, wood processing machinery, or medical technology. The encoders offer space-saving benefits for new machinery, as well as backwards compatibility with existing installations, and can be customised to work with all common magnet types.

“The DAX encoder represents an important milestone in the development of SICK’s encoder portfolio,” explains Darren Pratt, SICK UK’s Market Product Manager for Measurement and Instrumentation. “The encoders open up the availability of our magnetostrictive technology to industrial users for the first time.

“In just a few steps, SICK’s Online Configurator guides the user through the specification process to generate a part number and create an online order. Thanks to the platform concept of the DAX, application-specific versions can be generated quickly. There is also the flexibility of further customisation for new machine designs, or to enable adaptation to existing machines, including where proprietary magnets are already in situ.”

The DAX is being launched with three housing designs: one for integration

into industrial hydraulic cylinders; a low-profile type with block magnets for mounting in tight installation situations; and a version with an integrated slider that guides the position magnet, easing the requirements on alignment during mounting.

Integration into existing or new machinery is straightforward using standard mechanical interfaces. For electrical installation, the DAX® product family offers a CANopen as well as an analog output for either 0-10 VDC or 4-20 mA.

Via the CANopen variant, operators have access to diagnostic capabilities to monitor both sensor parameters and environmental conditions, including the magnet signal, temperature, piston cycles/travel distance, power supply and operating hours. Diagnostics can also output speed and time profiles to monitor for changes in machine performance over time.

In addition, the DAX encoders offer significant protection to ensure machine reliability in conditions where the power supply is vulnerable to fluctuations. The DAX offers integrated over-voltage protection to enable continued operation despite power spikes, while under-voltage conditions are alerted to the machine operator.

Machine designers are afforded significant flexibility to install the encoders in the tightest machine spaces, thanks to a minimal damping zone and an available measuring range between 50mm and 2,500mm, individually configurable in 1mm increments.

Specific variants of DAX can also use multiple magnets to provide differential values between positions along the measurement range, e.g. providing an output directly proportional to the amount of separation on a press. This feature can also be useful for example, to enable machine adjustments for format changes.

The SICK DAX encoders offer all the advantages of non-contact, wearfree magnetostrictive technology to measure absolute position, so no reference run is required. The linear encoders have an enclosure rating of IP65 and IP67, as well as a temperature range between -40 °C and +85 °C. Their rugged design and high shock and vibration resistance ensures longterm machine availability even under harsh application conditions.

For more information please contact Andrea Hornby on 01727 831121 or email andrea.hornby@sick.co.uk. www.sick.co.uk

• Registration is free

• 75% of stand space already sold

• Headline sponsors: Wurth Elektronik and Solid State Supplies

• Powered by Eureka, New Electronics and The Engineer

The Engineering Design Show (EDS) returns to The Coventry Building Society Arena on the 11th – 12th of October 2023. This two day exhibition has been curated specifically for design engineers and will bring together over 200 suppliers, thousands of products and all the latest industry innovations. There will also be 30+ hours of free conference sessions and workshops pulling together a highcalibre agenda. Previous speaking companies have included: Dassault Systemes, Wireless Logic, Small Robot Company and 42 Technology.

EDS has everything to support UK design engineers in 2023. Register your interest here to be the first to find out when registration opens and to keep abreast of all the latest show news: www.engineeringdesignshow.co.uk/register-interest

Exhibiting at EDS is a fantastic way to maximise your organisation’s exposure to the UK’s design engineering community. For more information, get in touch with simon.bonell@markallengroup.com and find out how we can tailer your package to meet your exact requirements.

- Previous exhibitor, Adam Miller, Field Sales Engineer from Ineltek on last year’s show.

“The resurgent Engineering Design Show exceeded expectations. Ineltek’s stand had a steady stream of relevant visitors from a variety of technology businesses. The two days flew by; we never reached the point where we had to kill time visiting other stands. EDS is back with a bang!”

Sponsors and Partners: Hosted by:

LiftEx 2023 , the free-to-attend flagship event of the Lifting Equipment Engineers Association (LEEA), will be held on 21-22 November 2023 at the state-of the-art Exhibition Centre in Liverpool, which is located on the banks of the city’s world heritage waterfront, gateway to one of the world’s most famous ports.

The leading networking event for the lifting industry is set to be better than ever and is proud to have the support of sponsors Rope and Sling Specialists (RSS), Delta Hoisting, Royal Van Beest and LHI Magazine.

An exhibition floor packed with major lifting suppliers offers the perfect opportunity for attendees from multiple markets, to gain vital lifting related knowledge and insights, as well as an opportunity to meet LEEA members and discuss ways they can help achieve best lifting practice.

Lifting is an essential function in many supply chains including Oil & Gas, Construction, Ports & Maritime, Logistics, Offshore, Manufacturing, Automotive, Utilities and Entertainment. All of these sectors

rely on a broad variety of cranes, hoists, platforms, cradles and their associated chains, ropes, slings and other lifting equipment – and not forgetting services such as inspection, maintenance and training.

The Lifting Equipment industry is constantly evolving with the onset of new materials, innovative ideas, better ways of doing things and the inclusion of modern technologies. A comprehensive portfolio of solutions to improve productiveness and efficiency while also ensuring safety for end users in all sectors will be on show.

It is vital that leaders responsible for procuring lifting equipment and services in any of these markets fully understand the risks, consequences and legal obligations, as well as being able to filter good practice from the bad. A series of informative speaker sessions at LiftEx, delivered by the LEEA team and industry experts, will discuss topics of recent interest, issues, trends, and recruitment strategies. There will also be learning and development as well as hands-on training sessions to give visitors the chance to top up their knowledge.

All of this makes a visit to LiftEx 2023 essential to catch up with suppliers, view demonstrations and explore the latest solutions from the industry’s top vendors.

And, of course, on the evening of 21 November 2023 – Day One of LiftEx – the fifth annual LEEA Awards ceremony will be held at the Rum Warehouse in Liverpool, which promises to be the Lifting Industry’s party of the year.

See the many exhibitors already confirmed at the exhibition website liftex.org, which also features a film of highlights from the 2022 show and there are news bulletins on what’s coming up in 2023. A floor plan is also featured for interested exhibitors. Requests will be dealt with on a first-come, first-served basis, so please contact Leah Phelps on +44 20 3488 2865 or at enquiries@L2Events.com to secure a sponsorship package or a prime position at the exhibition.

For more information, visit https://liftex.org/liftex-liverpool-2023.

For data protocols that are difficult to connect, the DataHub Tunnel/Mirror provides easy-to-configure, secure and robust networking. Eliminate the hassles of DCOM, detect network breaks quickly and recover from them smoothly. Access your remote data, not your plant systems. Connect and share data among locations with no DCOM or Windows security issues.

The DataHub Tunnel/Mirror goes beyond the basics, letting you integrate your data without exposing your network. Simply better networking.

You can take a big step towards compliance with the NIS 2 Directive by securing access to your process data.

You may have heard about the NIS 2 Directive. With the growth of Industry 4.0 and digital transformation, more companies need access to their process data. At the same time, cyber attacks on industrial systems are at an all-time high. So the EU has issued a tough new policy--the NIS 2 Directive-which takes effect next year.

Among the mandates, NIS 2 requires “a level of security of network and information systems appropriate to the risks posed.” In practical terms this translates into securing access to process data from corporate systems by segregating OT (operations) and IT networks, using a DMZ.

Skkynet provides a way to do this. DataHub tunnel/mirroring seamlessly passes OT data across a DMZ-enabled connection to an IT network. Most industrial protocols require opening a firewall to access the data, but the patented DataHub architecture keeps all inbound firewall ports closed on both the control and corporate sides, while still allowing real-time, two-way data communication through the DMZ.

Unlike MQTT, which cannot reliably daisy-chain connections across a DMZ, DataHub tunnel/ mirroring maintains a complete copy of the data and connection status from the source to final destination. It provides accurate indicators of data reliability at each point in the path.

And unlike OPC UA, DataHub tunnel/mirroring keeps all inbound firewall ports closed on the OT side, while still accessing the data. It faithfully replicates any or all of the full data set from source to user, maintaining the namespace.

NIS 2 takes effect next year, but you can secure your system now. Keep your OT and IT networks segregated with a DMZ, and pass the data securely between them using DataHub tunnel/mirroring

Although now supplying OEM’s in most market sectors, ODU were originally best known in the UK for their miniature military push-pull connectors.

The ODU-AMC® [Advanced Military Connector] series was developed to equip the ground-based combat soldier with an integrated set of high-technology equipment, linked to an array of battlefield information resources.

This range of rugged connectors offers high performance data-transmission, high band-width, high reliability and easy handling in harsh environments.

Whilst ODU undoubtedly established its pedigree in the military market, it has not been slow to transfer technology and lessons-learned and now supplies connector solutions to many other markets, such as medical equipment, instrumentation, factory automation & robotics etc.

In addition to their push-pull connectors, a range of modular, rectangular industrial connectors, the ODU-MAC® is available in several formats, incorporating signal, data, coax, power, fibre-optic & fluidic contacts, as standard connectors or as complex custom sub-assemblies.

ODU have used their experience to develop into a true ‘problem-solving’ connector manufacturer, working closely with their OEM customers to develop both connectors and packaging, so as to provide cost-effective solutions to the problems of modern-day electronics.

As suppliers, given the complete picture, they can usually come up with innovative proposals.

Let’s look at a couple of examples.

A medical equipment manufacturer needed a connector, in fairly large quantities, that was sealed and had ‘snatch’ capability. Of course, it also needed to be both smaller and more economical than anything else that they had come across!

They were originally looking at standard push-pull medical connectors, such as the ODU MEDISNAP®, which allows for various insulators and has 2 to 14 contacts.

But even this very small push-pull medical connector was seen as too large and too expensive – so it

quickly became clear that the answer was to develop a customized connector.

A major test equipment manufacturer had encountered technical and quality problems whilst trying to take substantial costs out of a new design, which needed mixed-signal bulk-head connectors.The solution was for ODU to provide two sub-assemblies, each incorporating a custom insert for a standard push-pull connector.

This insert has two central coax contacts, with flying leads, to handle high-frequency signals and a further 16 signal contacts mounted onto a small PCB, with a section of flex-foil ending in an SMT connector to the main PCB.

In both of these examples, it was the experience and expertise of ODU design engineers which produced a cost-effective solution for the customer.

However, ideas like these can only come about when we work together as equal partners. Suppliers such as ourselves are experts in what we do, as such we are a resource that should be more fully utilised in these lean times – so get in touch.

Classroom based “Live” webinars

On-site courses

Tailored options

For more information call 0121 601 6691 scan code for the training guide or email: training@bpma.org.uk

Fluid transfer products for upstream, downstream and refining

• Global inventory and locations

• Sales and technical support worldwide

• In-house engineering & design

• ISO 9001 accredited

• Pressure Equipment Directive

Products:

• Hoses and hose assemblies

• Hose & pipe fittings

• No-spill couplings

• Safety breakaway fittings

• Blow-Out prevention couplings

• Hydraulic Fracturing: Low Pressure Systems

• Loading arms

• Liquid level sensing

• Zero emission valves

T&D’s RTR500B series offers the broadest spectrum of functionalities: The battery powered wireless data logging systems can be housed in any location and combined with a broad variety of different data collectors to obtain information on temperature (-199 to 1700°C), humidity (0 - 99% RH), voltage, 4-20 mA, pulse, illuminance, UV and CO2 concentration.

The versatile loggers of the RTR500B series can be used to monitor operating parameters of refrigerators and freezers, as well as environmental conditions in museums and public spaces. Mobile solutions for outdoor use, in vehicles or during transportation complete the range of applications.

An ideal match is the RTR500B series of wireless data collectors for measuring, recording, monitoring, storing and downloading a wide variety of physical parameters. The loggers can be used in any location with four different types of base unit:

• RTR500BC for monitoring and downloading data via USB connection. It can also be used as a repeater for RTR500BW and RTR500BM

• RTR500BW monitors and downloads data via WLAN/LAN.

• RTR500BM connects for data transmission over a 4G mobile network.

• RTR500DC is a handheld data collector for areas where no network connection is available.

T&D offers the most extensive line of wireless loggers in the industry and the broadest choice of data collection options. All wireless data acquisition systems have been enhanced with Bluetooth communication for easy set-up of the RTR500B series in various environments. Inputs are automatically collected, monitored and all alert events are transmitted via cloud services.

T&D also provides a comprehensive suite of free software and apps for viewing, downloading, archiving and exporting collected data. It allows users to access data and configure their devices from everywhere:

• Data stored with T&D WebStorage Service can be accessed from anywhere and at any time.

• The T&D WebStorage Viewer is a useful web application for mobile devices such as smartphones and tablets. It allows easy access and vision of current readings data sent to the T&D WebStorage Service.

• With the T&D 500B Utility App for iOS and (Android will be compatible soon), all adjustments to basic and remote devices can be done via Bluetooth.

• The T&D software and internet services also allow users to remotely configure their base units and loggers, as well as set value thresholds for warning emails.

• Base units and loggers are configured, and value thresholds for warning emails (and SMS via RTR500BM) may be set remotely.

• A range of useful free tools support users in their everyday work with T&D data loggers, such as T&D Graph – an intelligent graphical tool for analyzing recorded data, utilities for carrying out settings and adjustments, a radio signal check tool, a data server application and much more.

For further information, please visit: www.tandd.com

Power supply component failures are perhaps the most common malfunctions affecting electronic devices. This is due to several reasons. First of all, the systems supplying current to the rest of the circuit are directly exposed to all kinds of input interferences – voltage surges, power shortage, etc. Another reason is the use of poor quality components in stabilizers and converters – especially electrolytic capacitors that are prone to the degradation process. The third reason is the lack of appropriate safety devices that could protect the components of the power unit from malfunction . Overheating, overload, and especially a short-circuit can be “lethal” for an overly simplified system. Unfortunately, the consequence of a power supply or converter malfunction leads to an adverse increase of voltage in the power supply circuit – in other words, one failure causes a chain of reaction and damage to not one, but several elements of the device. Such situations not only frustrate consumers but also cause losses brought by outages in industrial conditions – they increase repair costs and hinder the maintenance of machines and devices operating in complex automation systems, too.

Therefore, additional attention is required when selecting the power supply elements. Not only do they have to match the circuit parameters (with reasonable tolerance), but also need to be characterized with high quality and durability. That is why at TME we offer a wide range of good quality power supplies, power sources, as well as smaller components, such as AC/DC converters. In the latter group, today we

would like to introduce our customers to the AMEM-HAVZ and AMEL-HAVZ series from Aimtec

AMEM-HAVZ and AMEL-HAVZ –series converters

The AMEM-HAVZ and AMEL-HAVZ series are a group of compact AC/DC converters. They are designed to be powered directly from the power grid (from 85V to 305V AC), although they can also be used with direct current (100-430V DC). These components are enclosed in housings intended for through-hole mounting (THT). All products from this group have three basic safety devices: overload, shortcircuit protection, and the safety system preventing excessively high voltage at the output. It should be emphasized here that the manufacturer estimates MTBF (mean time between failures) at 3,200,000 hours – which proves the exceptional durability of the series elements.

The table below shows the basic, nominal parameters of each series. The products are categorized according to the output power that they can supply. Without electric load, most converters consume less than 100mW.

Characteristics of the AMEM-HAVZ and AMEL-HAVZ converters

Aimtec makes sure that its products meet the requirements set by a number of standards – thanks to which converters can be used in a wide range of applications. These standards include IEC62368, EN/UL62368-1 and EN60335, which, among others, define standards of power supply systems for RTV and household appliances, as well as IEC/EN60601 (medical equipment) and IEC/EN61558-2-16 (elements of switched-mode power supplies with an output voltage of up to 100V). The output voltage of all series is stabilized and the maximum amplitude of the output disturbances does not exceed 100mV, while the nominal voltage of the converters is maintained with an accuracy of +/-2%. Most of the presented products can work at temperatures ranging from -40°C up to 85°C, so they can be used in industrial conditions and outdoor devices, too, e.g. in energy, telecommunication or measuring devices.

Comau, a company specialising in the research and production of technological solutions for industry, based in Rugby, Warwickshire in the UK, is presenting four profiles of women who have chosen a STEM education and career path with the aim of inspiring other young women to take similar paths.

According to a survey by Tech Nation, funded by the UK government, almost three million people, or 9% of the UK workforce, are employed in the UK technology industry. Only 26% of these workers are women. But the gender gap, which is reflected in the world of work, is obviously something that starts before, that is formed upstream, starting with the choice of study path, which sees, for example, the STEM area clearly dominated by men.

Recently, the UNESCO Institute for Statistics (UIS) presented the report Women and Science, which showed that women make up around 30% of the world’s researchers and that less than a third of female students choose to study subjects such as mathematics and engineering at university. This gap represents a major limitation that has repercussions on the world of work and society as a whole.

It is for this reason that some of the ‘women of Comau’ have agreed to make themselves available through their story and account of their work in the field of technology for industry, as an example for all the girls of the new generations who may have doubts or be undecided but feel that STEM could be their life path.

In addition to Leah Wilson’s profile, here follows the short bios of three other women who work at Comau and whose stories can inspire other young women: Fariba Madhooshi, Lucrezia Morabito and Chiara De Ferrari.

Fariba Madhooshi, Product Manager / MATE-XT - from Iran to Italy, says its passion for what you do that counts even in male-dominated industries, regardless of gender or nationality

Fariba, holds the position of Product Manager at Comau, where she has worked for nine years. She moved to Turin in Italy after a three-year degree in her country, Iran. Her path was inspired by her father, a factory manager where she grew up developing

Leah Wilson is 22 years old and in Comau she holds the position of Graduate Project Manager, dealing specifically with managing and supporting the team of Project Managers in the internal governance of projects through the management of activities such as the control of compliance with internal P10 procedures, the management of timelines and QAMM milestones on MSPO and the monitoring and control of KPIs.

Leah started her career path during her engineering studies, with an apprenticeship in Comau that gave her the skills necessary to manage, assess and monitor projects and their performance and ensure alignment between projects and strategic objectives.

In addition to working at Comau in the project management team, Leah is currently studying for a bachelor’s degree in manufacturing engineering with the aim of improving her skills in project management, CAD and simulation activities, research and design theories, production and process management and materials mechanics.

“What I like most about my job at Comau is being involved in different projects every day that are always very interesting. The most challenging part is definitely managing and prioritising my time between work, university and other commitments. However, I like being busy, I am very organised and I think this has allowed me to give my best and always achieve excellent results in my career and studies”.

a love for this field. At Comau she was then able to grow, specialising in a specific product, the MATE XT, the exoskeleton for which she is now Product Manager. Fariba works every day with the exoskeleton which she sees almost like a son, in fact, thanks to her contribution, it has been transformed from an idea to a solution on the market. “One should not be afraid. There are many opportunities in this sector, regardless of whether you are a man or a woman. Today there are a lot of women around the world working in this sector, even on Linkedin you can find a lot of female professionals and be inspired by following their path”.

Lucrezia Morabito, - R&D Data Scientist and Product Marketing for Comau - her passion for mathematics made her discover how STEM can have concrete applications for everyday life

Lucrezia, R&D Data Scientist and Product Marketing for Comau now deals with the marketing aspects of mobile robotics and automation solutions in the renewable energy sector, analysing how technology can make a difference in the market to meet customers’ concrete needs and requirements. This aspect, the practical spin-offs of the theories learnt during her studies and professional career, is one of the elements Lucrezia loves about her work and her passion for practical things where creativity is not lacking. “Challenges are present in any work environment. However, it is crucial not to be labelled either by gender or by skills. STEM disciplines are disciplines that allow for multiple real-world applications that go beyond research exercises to provide benefits to the community, this goal

Inspiring Leah in her choice of study path was her family: “My grandfather worked as an engineer in the automation industry, my father as an electrical engineer and my older brother works in construction and engineering. The male figures in my family have definitely influenced me in my choice of studies and career path and I also want to be a role model for the younger women in my family”. Having role models to look up to is often decisive when choosing one’s career path. It is even more so when it comes to STEM subjects and in particular engineering, which is often prejudicially regarded as a typically male path: “The first time I went to a client I felt rather discouraged. I remember I was one of the few women wearing a hard hat, mask and safety boots and I felt a bit out of place. Even at university there were only two women in a class of 20. Fortunately,

should be the common thread that drives the entire scientific community, men, and women together”.

Chiara de Ferrari - Technical Project Leader Comau Germany - passionate about cars, mechanical engineering and rowing has followed her aptitudes without regard to prejudice.

Chiara de Ferrari is a mechanical engineer and Technical Project Leader at Comau Germany. For Comau, she is responsible for presenting customers with the most suitable solutions, also from a technical and mechanical point of view. Chiara is passionate about cars and loves science subjects, which is why she chose to pursue a degree in Mechanical Engineering. Today she is mainly involved in Powertrain and therefore in projects related to the welding line for engine support axles. His passions and his work are united by a love of challenges, perseverance, and commitment to achieve goals. But not only that, but they are also considered ‘manly’ activities. For Chiara, however, this has never been an obstacle because she has always had very clear ideas about what she wanted to do. “When I chose my course of study as well as the sport to do, I never thought that they were not suitable for me as a woman. For me it was normal, I had aptitudes and I followed them. Of course, I also noticed the gap between men and women. At university I was often the only woman in the lecture room and even today I still only have male interlocutors. What is lacking to overcome this cultural heritage is certainly greater exposure of young people to STEM subjects, starting at school”.

over the years I have seen more and more women on the worksites and in the corridors of the university and this has made me realise that fortunately things are changing. Today I find myself at Comau where I work with a very supportive and friendly team and where I am never treated differently just because I am young and a woman”.

Gaining work experience or an apprenticeship even while studying, according to Leah, is a great way for people who want to take up this job because it allows them to get an idea, quickly, of what this field can offer. Identifying role models and talking to as many people as possible about their career and experience is also a way to get passionate about STEM subjects. “Women especially need to be inspired from an early age about the engineering profession and where this profession could take

them. When I left school, I was the only woman in my year to enter an engineering industry. It is necessary to influence the younger generation more. I advise women not to be afraid to challenge themselves and step out of their comfort zone, because this job offers many opportunities. Don’t be discouraged and believe in yourself.” Recently, she has been following a new project which is a SE study intended to provide the necessary information required to define the future battery assembly strategy. She is responsible for assisting with the project management tasks during this project lifecycle, which include timing and resource planning/ tracking, MSPO controlling, milestone preparation, KPI’s and project review preparation. She will work closely with the project management team to follow the project from start to finish.

Vapour degreasing is the simplest but most effective industrial solvent cleaning process which, until recently, has been subject to little change since it was first invented in the early part of the 20th century. This is a very mature chemical technology, but legislation changes in recent years has impacted the industry significantly.

Chlorinated hydrocarbons have historically been the solvents of choice for vapour degreasingcompatible with most materials, stable in use, producing a non-flammable saturated vapour heavier than air at a temperature greater than ambient. Traditional solvents such as trichloroethylene exhibited all these characteristics but concerns about its carcinogenic properties and the danger to operators by exposure, led to a continuing search for a safer alternative. 1,1,1 trichloroethane based formulations became popular in the last century as a safer replacement. Although safer for users, it proved to be depleting the Ozone Layer and was subsequently banned. N-Propyl bromide (nPB) based formulations became popular in the last part of the century as a safer replacement, but this was later put in Annex 14 of REACH by the EU and can no longer be used as a vapour degreasing solvent in Europe. Countries around the world are now setting increasingly stringent environmental legislation to control emissions of Ozone Depleting and Global Warming industrial cleaning solvents. This has led to new chemical formulations being developed for industry.

EnviroTech Europe Ltd have been supplying vapour degreasing solvent formulations for over 20 years, constantly responding to regulatory requirements for environmental and safety laws and the need for improved standards. Staff and distributors are highly trained to work with customers to advise on the use of industrial cleaning solvents, helping them to navigate through legislative changes and ensure their vapour degreasing and cleaning solutions remain within regulatory boundaries.

Customers may have recently read in the industry press about another major industrial supplier ceasing production of their range of fluorocarbon containing metal degreasing and vapour degreasing solvents. They may be concerned that other major suppliers will follow suit.

Envirotech Europe would like to assure the industry of its intention to continue the manufacture of its ProSolv® range of metal cleaning and vapour degreasing solvents for the foreseeable future.

Zero Ozone Depletion Potential (ODP) and very low Global Warming Potential (GWP) solvent blend for high performance vapour degreasing

ProSolv®5408e ticks all the boxes with the perfect profile for a vapour degreasing solvent, developed by EnviroTech Europe Ltd for precision parts cleaning or cleaning automated machinery at strip down.

ProSolv®5408e offers improved cleaning at a lower cost, without compromising quality. Substitution is simple with little or no changes to equipment or control settings needed. A non-flammable stable azeotrope needing no testing for acid acceptance or stabilising additives, easy to use and maintain and safer for the workplace.

ProSolv®5408e is extremely effective for precision cleaning in high-tech industries such as aerospace, aviation, electronics and medical device cleaning. It can be used in most solvent cleaning systems, one tank vapour degreasing or multi tank immersion / vapour tank systems using ultrasonics or flush cleaning for complex mechanical and electronic components with blind holes and channels and close mounted electronics or for removing grinding and buffing soils on surfaces. Exceptionally low surface tension to penetrate micron sized holes and close contact surfaces.

ProSolv®5408e is highly effective when used with ultrasonics and can usually be used in existing degreasers or dip tanks. Ideal for precision cleaning and degreasing of electronics, metals and glass. It can be used to remove adhesives, fluxes, pastes, buffing compounds, greases, silicone oils, particulates, resins, waxes and other oils and soils. Soft on the environment, low solvent losses, reduced costs, sustainable and secure for the future.

• Fast precision cleaning, short cycle times. Stable with no additives, no testing required

• Alternative to Methylene Chloride, Perchloroethylene and High ODP/GWP Fluorocarbons

• Excellent choice to replace flammable solvents such as MEK, Acetone, Isopropyl Alcohol (IPA) or Hydrocarbons

• Established replacement for Trichloroethylene, n-Propyl Bromide (nPB) and other now banned solvents

• Can be used in any vapour degreasing equipment, lower energy consumption and lower maintenance. Compatible with a broad range of substrates

• Improved productivity, parts exit the machine cool, dry, spot-free with no drying required

• High density solution, excellent for ultrasonic cleaning

• Mid-range temperature operation, easier handling, mid-range boiling point, processed components easily handled (48°C)

• Very low surface tension for penetration into the micron level crevices and holes, efficient cleaning in tight to reach places and complex geometries

• Easy process monitoring with minimal effort and minimal waste generation, easy reclamation for reuse

• Minimal non-volatile residue

• High Solvency (KB Value 98) for a variety of contaminants

• Safe for the environment, zero Ozone Depletion Potential (ODP)

• Very low impact on Global Warming (GWP)

• Non-hazardous for transportation

• Non-flammable (No Flash Point)

• Not classified as a carcinogen

ProSolv®5408e vapour degreasing solvent is manufactured in the United Kingdom and available on short delivery times through our dedicated team of distributors worldwide. Please visit our website www.envirotech-europe.com for information about all our products and further information on ProSolv®5408e

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form