Based in Alton, Hampshire, Testo have been operating for over 30 years as the UK subsidiary of Testo AG, selling products throughout the UK and Ireland. Testo Limited also offers instrument service and calibration from our independently accredited ISO 9001:2008 and ISO17025 laboratory. The requirements for practical measurement solutions are becoming increasingly more complex and customised.

Testo is a leading manufacturer of high quality measuring instruments for many applications and sectors, such as the Industrial Production & Manufacturing sector. Innovative measurement technology from Testo supports production processes in every phase, from development to the finished product. Such as, Thermal imaging to monitor electrical boards and identify worn parts in machinery through to Welfare Kits to ensure the environment in which employees work is comfortable, safe & Legal.

We heavily invest in product research and development to guarantee we offer instruments that deliver durability, functionality and ease of use. For the purposes of lowering costs in production, and in the final product, the industrial sector is reliant on resource efficient machinery whose mechanical, electrical or pneumatic drives consume as little energy as possible.

Manufacturing to consistently high standard of technology by investing in the most modern equipment, solid background knowledge and years of experience are the basis for you being able to safely reproduce high quality results. Testo’s reliable measurement systems can consistently monitor and regulate the production and the optimum adjustment of your environment, thus reducing energy consumption.

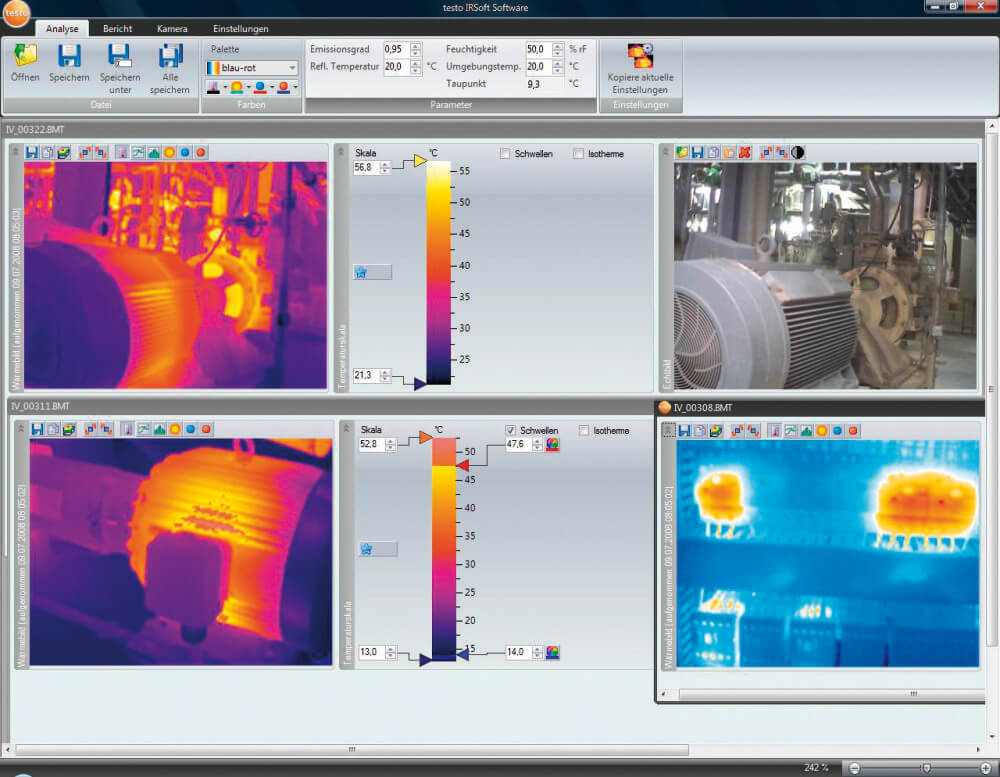

The use of thermography cameras has caused a quantum leap in the progress of predictive maintenance and inspection programs, across industrial domains. It has also revolutionised the industry by contributing to substantial cost savings for manufacturers, while enhancing the quality of inspections for service providers. Use on a daily basis to help save time, reduce costs and ensure all relevant systems are operating properly and safely. In mechanical systems Infrared Cameras are useful for detecting irregularities usually caused by friction due to improper lubrication, misalignment, worn components or mechanical loading anomalies. Thermal Imagers are one of the fastest rising preventive maintenance tools in industrial inspections for monitoring mechanical and electrical systems within the production processes.

The key benefit of utilising Thermal Imaging as a maintenance tool is that, it allows inspections to take place during live operations. Imagine being able to inspect bearing housings on the production line, without having to cease production or disassemble the machinery. With thermal imaging, heat profiles of important components can highlight abnormalities allowing further focused inspection and effective maintenance on any machinery.

If you would like to find out more, either visit www.testolimited.com or call 01420 544433 to speak someone in Technical Sales.

Leave a Reply