LB Foster Materials Handling has begun work on an automated engine transfer contract for the engine manufacturing plant of Cummins in Daventry.

Cummins is a global power leader that designs, manufactures, sells and services diesel engines and related technology around the world. The company serves its customer through its network of 500 company-owned and independent distributor facilities and more than 5,200 dealer locations in over 190 countries.

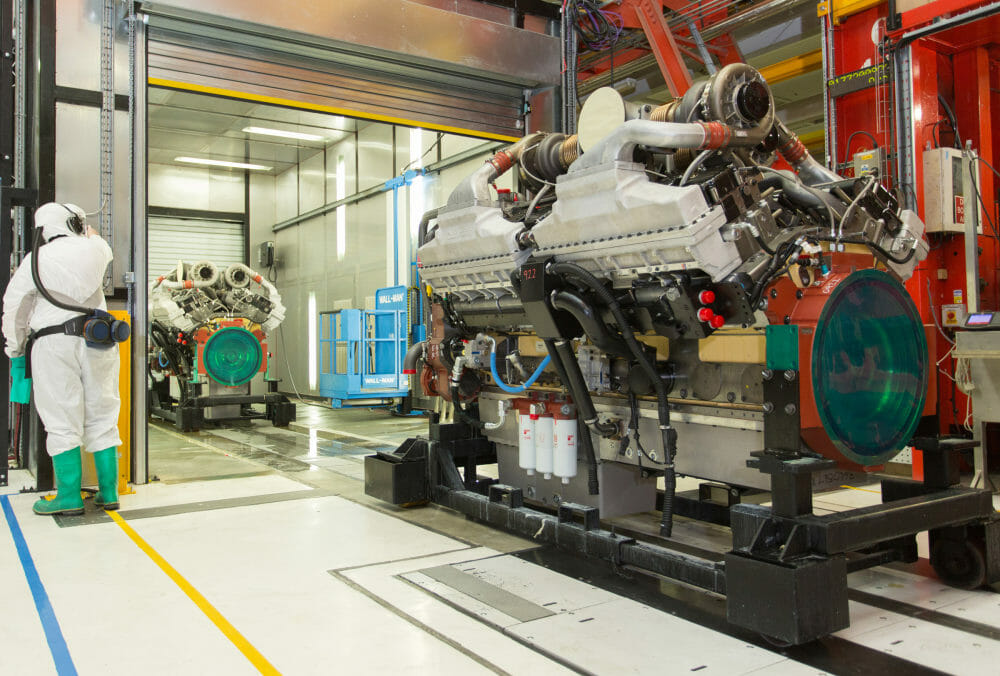

Approximately 1,000 people work at the Daventry plant, manufacturing high horsepower diesel and gas engines which range from 38 to 91 litres. The engines are made primarily for the international market; they are exported all over the world to be used in a variety of industries from marine to mining.

Every engine is spray painted in the specific colour requested by the customer. The prestigious contract awarded to LB Foster is for two automated systems to transport the engines through two new paint processing lines. Both lines have been designed to process a maximum of 10 engines at a time, each weighing up to

12 tonnes. One line has already been finished with the second due for completion later this year.

Cummins have had previous experience of working with LB Foster as the company has manufactured conveyor systems for several assembly lines in Daventry. As a result the equipment is known to be well engineered, robust and very reliable.

Ian Bennion is the manufacturing engineering leader for Cummins, he explains why LB Foster was selected for this important project, “Automation in manufacturing is quite a niche market however it was a still a competitive tender.

“Confidence in LB Foster’s ability to complete the task was the deciding factor.

Leave a Reply