It is rare that pipe systems solely have one inlet and one outlet. The diversity of process applications means that piping is forever splitting, diverting, separating and rejoining. Whether it is a fluid that is the common feed to different outlet processes, or whether it is cleaning fluids or gases that need to be allowed into pipe systems to clean, flush or sterilise the internals; groups of tees, pipes sections, elbows and connectors are often mated together as a manifold usually spread out in 2d and created entirely from a 2d P&ID drawing.

The usual view of manifolds is simple. Inlets, cross connections & outlets often mounted across a backboard, wall or cabinet.

However, the latest development in 2d manifolds is to make them in 3d and in one piece!

At the forefront of this unique way of assessing plastic manifolds is GEMU. They have literally pioneered the concept of machining manifolds and valves into a single piece of plastic block material.

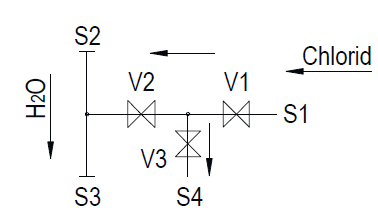

Example: Chlorides injection into water with double block and  bleed.

bleed.

Normal layout includes 2 Tees, several pipe pieces, 3 valves, cutting, layout, jointing and testing. It also means more time, potential leaking joints and careful measuring of piping to make the correct dimensions.

The GEMU solution

One block – 3 valves – fixed dimensions and less joints to leak!

Another example: Distribution Manifold

Time consuming fabrication removed using one block. Quick installation, less leak paths, simple ordering, stocking and less space!

Advantages of multi-port valves

Advantages of multi-port valves

- Individual, customised layouts and very flexible design

- Very compact

- Fewer fittings, welds or cemented joints → fewer potential leakage points

- Lower assembly and installation costs

- Low hold-up volume, smaller wetted area

- Operators and diaphragms/seals from the proven GEMÜ modular system

- Produced from a single block of material (standard materials PVC-U, PP, PP natural, PVDF and PEEK); further materials on request

- Standard connections: threaded sockets, solvent or welded unions

Solutions are developed together with the customer

GEMÜ supports its customers at the planning phase with ideas and initial drafts. The drafts are laid out for design purposes into the GEMU 3D CAD system, agreed in close cooperation with the customer and finally processed in a state of the art efficient machining centre. Every day, the GEMU Design Centre turns out new customised block designs.

Time and cost optimized

The bodies of plastic multi-port valves are made as standard of PVC-U, PP, PP natural, PVDF, PEEK or PTFE but designs are also possible using other materials.

Multi-port valve blocks are generally produced by machining from a solid block of plastic material. In the case of larger quantities, GEMÜ can develop individual solutions together with the customer based on an injection moulding process. This leads to substantially lower unit costs. Of course they also develop and manufacture the moulding tools for themselves. GEMU therefore have control over the whole process, which is fast, flexible and in line with high quality requirements.

Or why not use extendable blocks to mix and match a manifold!

Extendable plastic multi-port valves are made in sections so they can be clamped together. This makes for “a la carte” valve manifolds whereby the assembly might use components to produce 1, 2, 3, 4, 5, 6 or more inlets and outlets. Typical application is in skid building for chemical mixing or dosing where the outlets from the skid may be single or multiple pipelines.

To view more details about GEMU plastic blocks see the

GEMU GROUP YouTube links below.

GEMU Plastic Valve Manifolds – Explain It Video

Or see Gemu on the internet

Or email us direct

Leave a Reply