Edge card connectors are embedded devices that mate with the edges of single-sided or double-sided printed circuit boards (PCBs) in order to provide an external electrical connection. Industry standards define power specifications such as voltage levels, power pin placements, and power requirements. For example, PICMG 1.0/1.2 standards define the power specifications for peripheral component interconnect (PCI) and industry standard architecture (ISA) buses. The contacts of edge card connectors are made of metal and are plated with a thin, metallic coating that improves conductivity and prevents rust and corrosion. Plating materials include gold, copper, nickel, and silver. Contacts are housed in a termination assembly that is usually made of plastic. Edge card connectors are used widely in personal computers and, depending on their components, are suitable for lead-free applications.

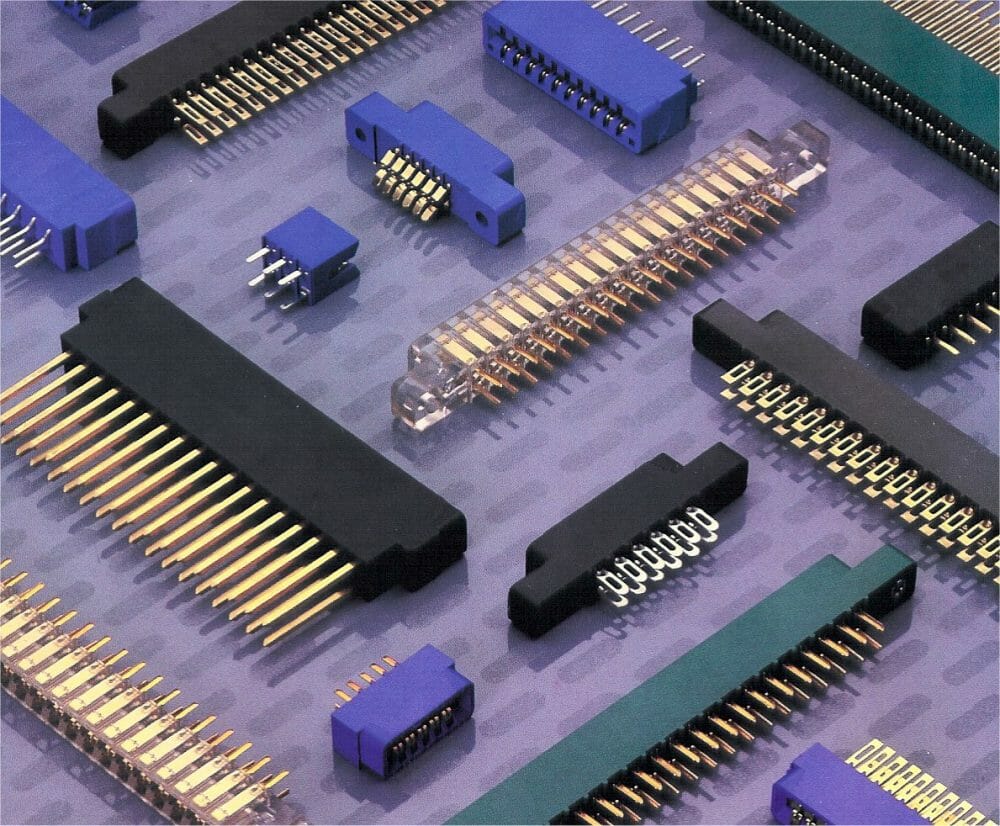

We offer a complete line of Sullins and Micro Plastics Edgecard Connectors ranging from .050″, .100″, .125″, .150″ and .156″ contact spacing with Wire Wrap, Dip Solder, Right Angle and Extender Card termination styles. These connectors are available in a wide range of sizes from 2 to 120/240 positions depending on contact pitch and include a variety of mounting configurations.

In2Connect are specialists in 200/250 C High temperature, long life connectors specifically designed for burn-in oven and automatic temperature testing applications; sockets for Test & Burn-in of wafers and IC packages, sockets for Test & Burn-in of LCD modules, sockets for Test & Burn-in of SIMM and DIMM modules and customer specific test socket contactor solutions. Each Burn-in chamber will represent a precisely controlled test environment over a range of time and temperature settings. System electronics are able to heat to the chamber and to apply high voltages to fully exercise the devices on the burn-in board.

Burn-in boards interface between the burn in system and the socket. Each burn-in board connects directly to the system architecture through a backplane at the rear of the chamber. Burn-in boards are often complex, multi-layer boards designed to handle extreme temperatures and are designed according to the customer’s specific application.

Burn-in sockets and connectors are the interface between the semiconductor device and the burn-in board.

These often provide a challenge in the burn in process because all pins need to be making good contact for a valid burn-in outcome ~ not a problem when you choose a Sullins interconnect.

With our long established supply chain, In2Connect has access to the largest selection of 100% RoHS, UL/CUL approved edgecards and headers in the industry, including the McMurdo 0.100″ Modular edgecard range with its very flexible contact count.

With established manufacturers like CINCH and TE Connectivity (Tyco) reducing their legacy edgecard ranges we’ve taken on new, cost effective products, with 2 to 188 contacts depending on the series, built in China by EDAC.

We design, engineer, manufacture and distribute a wide variety of standard, semi-custom and fully custom edgecards and headers; which have been used, amongst others, in applications ranging from Aerospace through, Medical, Wireless, Communications and Semiconductor. If you need a customized connector for your unique application, our team of experts will help you design and develop the best solution at competitive prices. We can accommodate all types of edgecard connector orders; large or small. We supply leading OEM’s with volume solutions, but we’ll even accept orders as small as 10 connectors.

Leave a Reply