Ricardo’s £10 million Vehicle Emissions Research Centre (VERC) sets a new standard in vehicle testing technology, providing a world-class facility that will enable the development of next-generation of clean, low carbon vehicles.

One of the international automotive industries most advanced emissions test facilities to date, Ricardo’s new VERC has been designed from the outset to accommodate the development requirements of the next generation of more environmentally friendly and fuel-efficient road-going vehicles. It also provides not just one of the world’s most rigorous vehicle test environments, but also amongst the most operationally efficient.

Meeting the development challenge of future clean vehicles

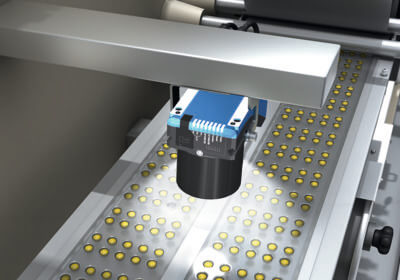

The VERC is capable of carrying out climate controlled vehicle tests with a temperature range of -30 to +55 degrees Celcius and with humidity regulation. Configured for 4WD powertrains of up to 300 kW and capable of simulated road speeds up to 250 km/hr, it is capable of testing anything from the smallest passenger cars to light trucks of up to 3 tonnes, including advanced technology hybrid electric vehicles and their associated energy regeneration systems and stop/start operation. For such electrified powertrain applications the VERC is also able to measure battery state of charge in addition to vehicle emissions – an important consideration for increasingly popular plug-in hybrid vehicles.

The VERC’s exhaust emissions measurement systems are capable of supporting engineering projects to the regulatory standards applied in all parts of the world, up to and including the very highest Euro 6/7 and US SULEV standards. A novel feature in this respect is the triple Constant Volume Sampler (CVS) tunnels; typically facilities of this type have separate CVS tunnels for gasoline and diesel projects, but the VERC additionally has a third tunnel exclusively for the very lowest SULEV emissions.

The facility has been designed to meet all the demanding requirements for the measurement of regulated emissions and the development of advanced after treatment. State-of-the-art-gas analysers enable the real-time measurement of CO, HC, O2 and NOx plus both EGR and exhaust CO2, whilst specialist approaches for NOx speciation (FTIR) and detailed particle properties (mass, number, size) are included in the fully integrated emissions measurement capability. The vehicle soak space has been constructed as a series of independent climatic zones to ensure sub-zero soaked vehicles are maintained at their target temperature throughout their transition to the test cell and it also includes two integrated cold boxes with separate climate control.

Future proofed design

The design of the VERC has been future-proofed both in terms of its ability to be configured for anticipated future regulatory needs, as well as being extendable to provide further additional capacity. All of the civil engineering works necessary to provide a second test chamber have already been completed as part of the initial development, so that fit-out could be completed rapidly if Ricardo requires this additional capacity. Similarly the design of all the plant installation is such that a generous amount of space is provided such that additional systems can be installed or equipment replaced, with minimal disruption to the ongoing work of the centre.

With the scalability and future proofing incorporated into its design, the new facility will be an extremely valuable testing environment enabling Ricardo and its clients to engineer vehicles to future emissions regulations.