A growing number of global regulations are affecting temperature related processes and quality procedures, driving the need for more accurate measurement, precise control, and secure recording of validation data. For example, heat treaters making metal parts for aerospace and automotive industries need to comply to strict standards such as Nadcap, AMS2750, CQI-9 and TS16949, while pharmaceutical manufacturers need to meet FDA 21 CFR Part 11 in terms of electronic records and signatures. Food and beverage industries need to follow GMP and HACCP guidelines and if wanting to export certain food types, also need to comply with regional FDA regulations for thermal processes. Engineers and quality personnel have many levels of control and data acquisition products, solutions and methodologies to choose from to help meet these standards, but which methods are best and what features should you look out for?

Eurotherm™ by Schneider Electric™ have over 50 years’ experience in the design and manufacture of control and recorder products and solutions, specifically designed to help manufacturers comply with the requirements of industrial processing standards. Here are a few aspects to consider.

Measurement Accuracy

Look for I/O (Inputs and Outputs) that are isolated from other channels and circuits, with specifications that quote the noise rejection and long term drift. A high noise rejection ratio and low ppm (parts per million) drift/year will help aid compliance with temperature related standards by easily maintaining stability and accuracy within the specified calibration periods.

The nanodac™ recorder/controller offers accurate I/O, precision PID control and secure recording in a ¼ DIN box

Eurotherm controllers and recorders offer protection from these kinds of issues thanks to high quality components and good analogue circuit design.

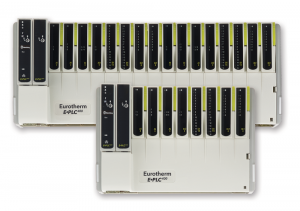

Precision Control Strategies

Look for controllers that use PID (Proportional, Integral, Derivative) control in combination with additional algorithms specifically designed to maintain control in your applications.

For example in Eurotherm controllers and PLCs, the temperature overshoot, lag and instability commonly seen in thermal processes can be better controlled using PID with specialist features like Cutback (overshoot inhibition) Cascade (fast response to setpoint change to reduce temperature lag in the load), Gain Scheduling (multiple PID sets for extra heat or cool gain, that help achieve difficult to reach set points) and Autotune (automatically sets the best parameters for your process).

E+PLC400 combines precision PID control, secure recording and PLC functionality in a scalable solution

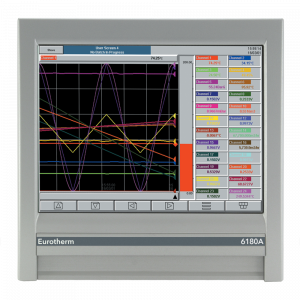

Secure Digital Data Recording

Look for products that record data at the point of measurement so data is not lost if the communications fail. A secure file format is also a neccessity, rather than commonly used editable .csv files.

Eurotherm recorder products store data in internal memory so it’s still available for archiving if communications are temporarily broken. The self-healing Store and Forward™” strategy then backfills data to the archive servers once communications are restored. A secure tamper resistant file fomat is used, only viewable using specific software and full featured recording products have batch, and security management options that provide a tamper resistant audit trail for recording User Names, Passwords and Access Permissions.

For more information on how Eurotherm control and recording can help you meet your manufacturing and processing regulations visit www.eurotherm.co.uk