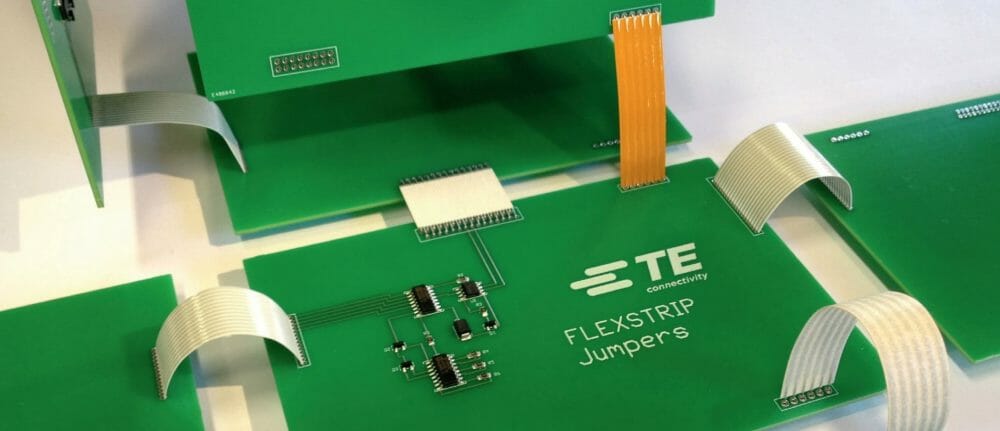

DARMSTADT, Germany – February 21, 2017 – TE Connectivity (TE), a world leader in connectivity and sensors, is offering Flexstrip jumpers to provide multi-conductor board-to-board connections that can be flexed repeatedly without failure. They provide a high-performance alternative to conventional point-to-point wiring.

Flexstrip jumpers are suitable for a wide range of applications, including computers, handheld terminals, barcode readers, printers, consumer electronics, automotive, industrial machinery, and household appliances.

The Flexstrip family comprises several different types for diverse applications and operating conditions. They all have a flat conductor construction that provides unrivalled flexibility and resistance against vibration and high flexing cycles. The jumpers suit all standard printed circuit boards (PCBs) and do not require any crimping or cutting, ensuring an easy assembly and soldering process as well as low installation costs.

The construction of the flat conductors is achieved by a special manufacturing process involving the rolling flat of round conductors. This is what gives the Flexstrip its high flexibility. Conventional round pins at each end ensure simplified assembly and soldering. The smooth notchless transition from the flat conductor to the round contact pin guarantees a termination area that is break-proof and free of stress.

When electronic devices are subject to strong vibrations, resonant frequencies can occur in the structure of equipment and the PCB. When PCBs are connected by point-to-point wiring, this can lead to high levels of stress and ultimately wire fracture, especially at the termination points—typically the weakest links in the system. With their flat conductor construction, TE’s Flexstrip jumpers are much more capable of absorbing such stresses, since stress is transferred uniformly along their entire length. In addition, Flexstrip jumpers act as a vibration absorber, ensuring that any vibration is quickly dissipated and not transferred to other areas of the equipment where additional problems may occur.

TE’s Flexstrip jumpers are also simple to use, providing connections between PCBs without the need for any wire stripping or preparation. No crimping or cutting is required. They are available with various insulation materials—Nomex, Teflon, polyester and Kapton—for industrial, automotive and military/aerospace applications.

Nomex aramid insulation is offered as an economic material for general purpose applications where a change in direct current resistance due to humidity is not critical. Polyester has less high temperature resistance, but excellent electrical and mechanical properties, and is suitable for use in high humidity applications. Kapton polyimide has excellent mechanical properties, especially at very high temperatures. Teflon fluoropolymer has superior electrical, mechanical and chemical properties for demanding situations and is particularly suitable for applications where there is moisture or changing climatic conditions.

The jumpers can be supplied with between two and 65 conductors, in nine different pitches. Jumper lengths are up to 30 inches, and various pin lengths are available. There is a choice of 15 different terminations on either end. The copper conductors are tin-plated for easy soldering.

Flexstrip, TE, TE Connectivity and the TE connectivity (logo) are trademarks of the TE Connectivity Ltd. family of companies