Panasonic presents the world’s smallest optical sensor for automation technology!

Panasonic have been world leaders in the design and manufacture of small, compact photoelectric sensors for use in factory automation and industrial machine control for over 15 years. Now the latest technologies in electronics and product packaging have resulted in the introduction of the EX-Z Series of Ultra Miniature photoelectric sensors offering a reduction in packaging size of up to 50% on previous generation products.

Innovators of product miniaturisation, Panasonic are world leaders in the area of optics with expertise gained from AV flat screen technology and award winning Lumix camera design. This knowledge and know-how is seamlessly transferred to a portfolio of state of the art factory automation products including an extensive range of sensing products that complement a compact range of PLC/HMI products and world leading Servo Drive and Robot control. The philosophy behind the miniaturisation of these products ties in with the efficiency of smaller machines allowing increase in production capacity whilst reducing costs.

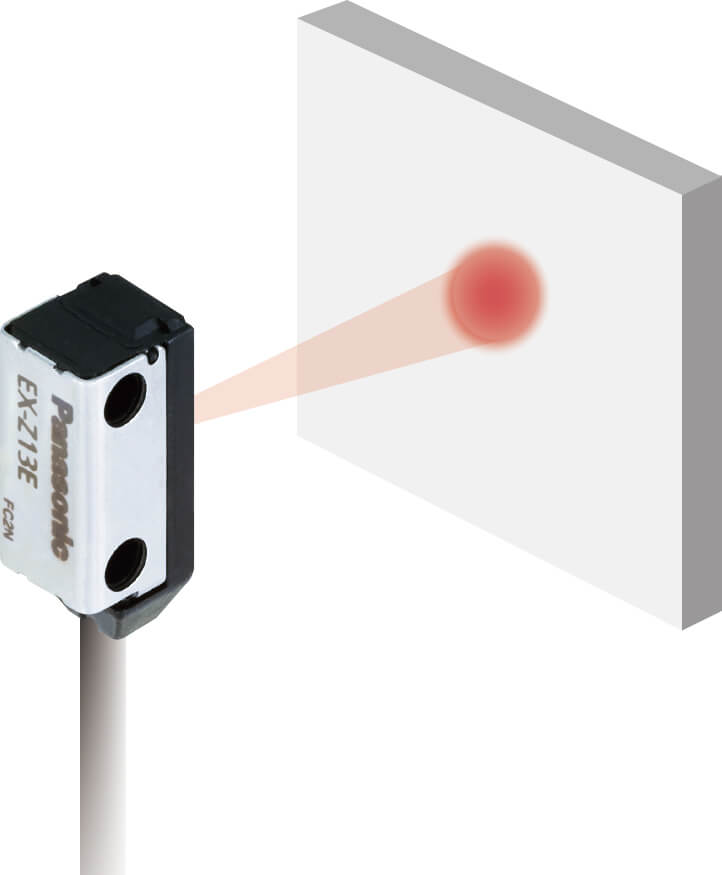

The brief behind the development of the EX-Z Series photoelectric sensor was to build the most compact fully integrated sensor for the target markets of Medical Technology manufacturing, Electronic manufacturing and Assembly/Small Parts manufacturing. Integration of optics, electronics, LED indication and output circuitry in a single housing with a physical thickness of only 3mm is the result and offers exceptional performance from such a package with a resulting detection range of up to 500mm which is ideally suited to its target markets.

The WL-CSP (Wafer Level Chip Scale Package) technology enables the miniaturisation of the EX-Z series and is a micro-SMD technique allowing the size of the semiconductor to occupy more than 80% of the total volume of the complete housing. The process means the “Die” is bonded face down on the circuit board and lacquered before the final mounting of the optical elements, which are integrated into the chip housing and are adjusted for optimal beam alignment during the process. The whole process is fully automated and the WL-CSP technology is a development of the processes used in medical technology in particular endoscopy.

The high performance characteristics of the EX-Z series are aided by the integration of a powerful LED (peak wavelength 650nm, modulated) into the transmitter element of the sensor. This together with the small diameter transmission port results in an extremely concentrated beam source that is normally only associated with laser based technology.

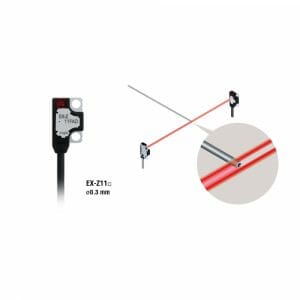

A traditional thru-beam sensing solution for pin presence on an LED or an Integrated Circuit during manufacture would typically be solved with fibre optic based sensing technology, where the compact fibre sensor optics are mounted separately from the amplifier as space is normally at a premium. However the technology requires adjustment during installation and commissioning and is also liable to possible inadvertent operator intervention during the machines operation. The EX-Z Series eliminates such possibilities as there is no adjustment required and due to their compact nature they can easily be embedded into the structure of the machine minimising operator intervention.

The size and manufacturing process involved in the production of the EX-Z Series ensures highly reliable operation which is ideal for the laboratory automation industry where such performance is demanded. In addition to the IP67 protection rating of the sensors there are additional models available with high flex cables that are ideally suited to repeated movement in machines where linear and robotic stages are used. Additionally these features are equally applicable to the areas of electronic manufacture and assembly where the industry demands fast, reliable and accurate sensing. With the trend of electronic components continually reducing in size it makes sense that the products used to create them are of the same technology and size.

The EX-Z Series sensor offers a wide range of options for thru-beam sensing with two distinct packages offering front and side sensing meaning a flexible choice on mounting options. In addition three sensing ranges, 50mm, 200mm and 500mm ensure accurate and reliable detection in numerous applications where accuracy and flexibility can be traded off against each other. The already mentioned standard and high flex cable solutions, together with a choice of PNP or NPN transistor outputs ensure that the sensors are designed for a global market which is synonymous with Panasonic and their vision to continue to drive the boundaries of innovation in the field of automation.