Modern techniques have made the process of commissioning a manufacturing tool easier and more cost-effective. Jeff Kiernan, Commercial Director at Dawson Shanahan, explains.

Efficient manufacturing relies on high quality tooling. The tooling determines everything, from the speed at which parts are made to the repeatability of manufacture in high volume production – and, ultimately, the quality of the finished part.

Effective tooling design requires a deep understanding of the conditions that a tool will encounter during machining or cold forming. This informs the way the tool is built and the materials used, as well as potential modifications to process criteria.

The designer must consider many factors, including: tolerances in the finished part; mechanical strength and rigidity; cutting tool strength; sacrificial or weak links; machine tool speed, feed and size; and disposal of swarf or other waste.

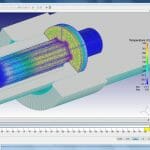

Powerful computer-aided design and modelling software has helped to streamline this process in recent years, while other software has helped to reduce tooling costs.

Managing misconception

Tooling is usually considered an expensive process, but this is a misconception. Modern techniques have cut the cost of conventional tooling for CNC machining and precision cold forming. In the past, cost and time delays often occurred because tooling development was largely an iterative process – with improvements made through a series of prototype stages. While this methodology remains, software tools – such as SolidWorks and DEFORM – allow tool design, analysis and testing to be done on-screen rather than in the tool room, so the ‘correct’ tooling can be engineered first time. For example, DEFORM simulates deformation and die stress analysis – banishing iterative processes, and ensuring that a die is ‘right first time’ when it is cut.

Cost confusion

Software has also made it easier for engineers to assess the time, labour and materials required to produce individual tool sets. Historically, there has been confusion over tooling cost, and how it is charged to each customer. Because there were no standard definitions to guide cost calculations, suppliers adopted a variety of practices to calculate the cost of developing tooling.

Dawson Shanahan’s approach is to work with each customer, explaining how costs are calculated and then finding the solution that works best for both parties. This might be a one-off charge, or an agreement to amortise the cost of tooling across the lifetime of the project. A critical step is always to consider how the cost of both tooling and the overall project can best be reduced, while ensuring that part quality and delivery deadlines are unaffected. It is usually better to invest slightly more in the tooling if this significantly reduces part costs. This is especially relevant in high volume projects.

For instance, although tooling for precision cold forming is more costly than that for conventional CNC machining, cold forming is usually more cost-effective: it is faster, uses less material, and produces a higher quality component that needs minimal post-processing. As a result, part costs are lower, while less waste is generated and less energy used.

Tooling may seem just one part of the manufacturing process, but approaching it in a measured, scientific way can reap huge benefits.