AutoCoding Systems has recognised that there is a growing requirement to communicate with and collect data from a wide range of devices, as well as interface to various business information systems to enable factories to work smarter.

As a global provider of automation solutions to factory production and packaging areas, AutoCoding Systems has developed a suite of modular software products to facilitate processes such as device integration, data collection and integrity, code deployment and packaging verification.

The entry level web-based AutoCoding product can be used to set-up and control packaging line devices, such as coders, barcode scanners and inspection equipment, irrespective of brand. The centralised application automatically deploys secure set-up and message data to one or more packaging line devices, thereby reducing downtime, as well as eliminating the risk of coding and packaging errors. The resulting business benefits include increased speed and reliability of line set-up, reduced job changeover time, reduced risk of human error and the ability to manage complex packaging formats.

The AutoCoding suite of modules gives additional functionality and greater scope for the collection of data. For example, the Paperless Quality module automates both in-line and off-line routine quality checks. The AutoCoding line terminal can be configured to individual requirements creating various methods for capturing data which can then be used for reporting purposes.

Details of all QA checks are consolidated into the AutoCoding audit log resulting in a reduction in the amount of physical paper records that must be retained and subsequently stored.

Other modules include Inspection Reporting to monitor the performance of, and collect data from, multiple checkweighers, metal detectors and x-ray equipment. Real-time data can be collected relating to contaminant detection rates, weight and overfill allowing corrective action to be taken, as required. Easy

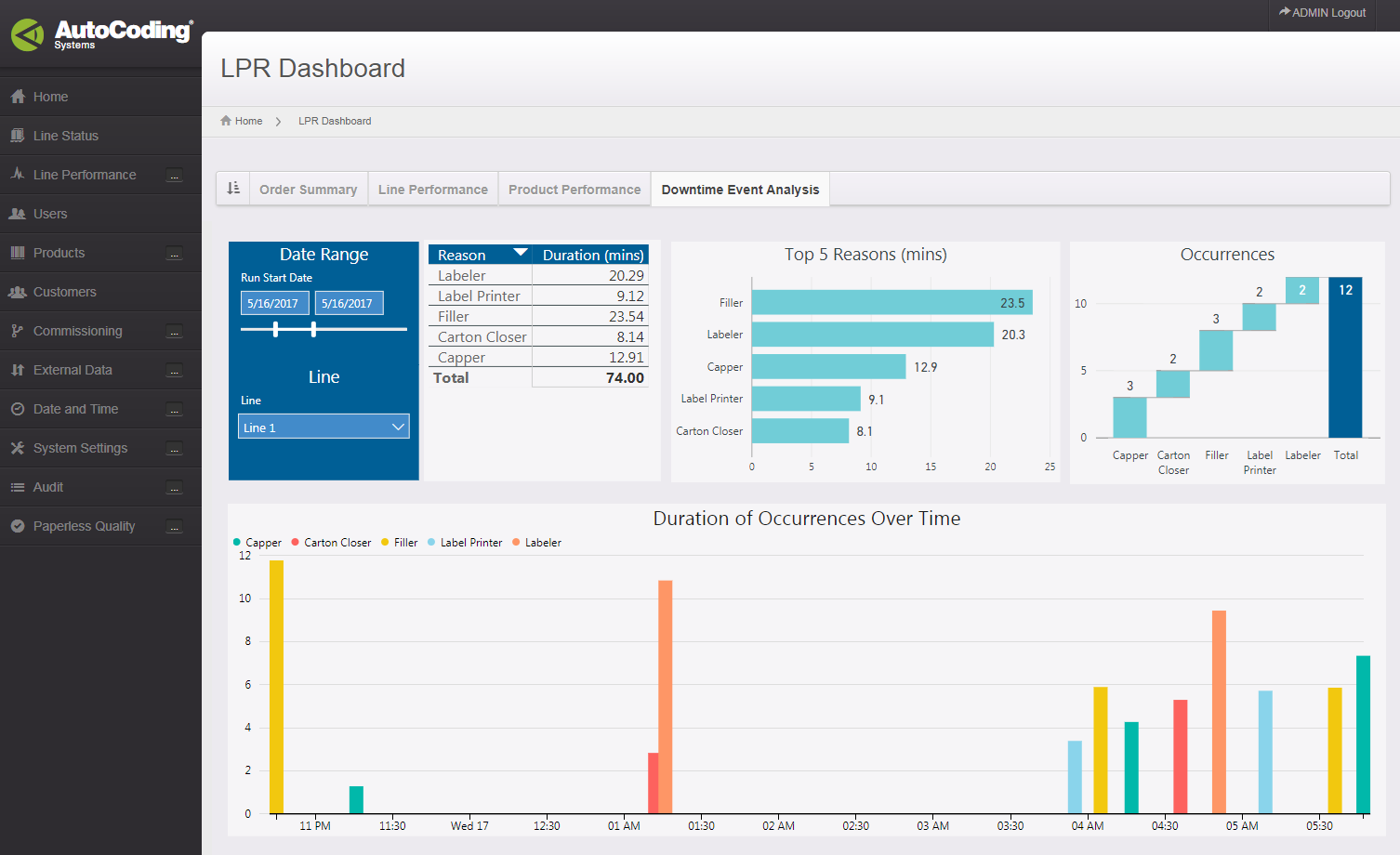

The Line Performance Reporting module captures real-time manufacturing data which can then visualised in customisable reports to display accurate packaging line / device / product performance data.

The latest concept developed using the latest software engineering technologies is the AutoCoding IIoT Gateway. IIoT technology provides consistent mechanisms for cross-application and cross-device communication. This enables the collection of rich data and statistics from production line devices which previously could not easily participate in the movement towards a connected factory floor. The AutoCoding IIoT Gateway aims to reduce the cost and increase the effectiveness of integrating users, data and applications with data and equipment on the plant floor.