Special filters allow for accurate temperature measurement in high temperature furnaces

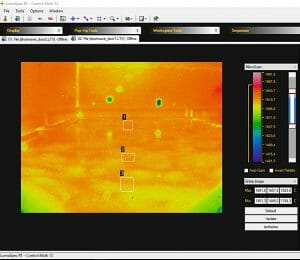

This FurnaceSpection™ thermal imaging system by LumaSense Technologies is designed and developed for continuous temperature measurement inside high temperature furnaces in refining, metals, and glass production.

The FurnaceSpection™ system provides users with a real-time tool for quickly and accurately identifying process abnormalities before they develop into problems that can lead to unplanned outages. This radiometrically calibrated imager accurately measures the temperature of product, refractory, and heat transfer surfaces inside natural gas fired furnaces.

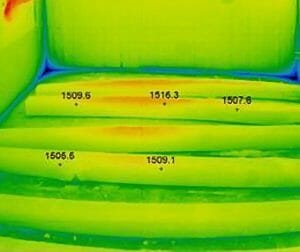

The new generation of this high-grade imaging system is equipped with a special borescope optics, which enables monitoring of the temperature distribution inside e.g. melting furnaces through the furnace wall. By utilizing high quality optics, a resolution of more than 300,000 pixels can be achieved, and the borescope lens system is available in a number of different lengths to suit virtually any application and need.

FurnaceSpection™ helps operators monitor and control process temperature uniformity through streaming images documented by a powerful software for analysis and historical trending, outputs to automation and DCS, and a real-time web server to broadcast images on the plant’s local network.

The radiometrically calibrated imager accurately measures the temperature of product and refractory, inside natural gas fired furnaces. The user is also able to monitor flame condition, thereby reducing the production of NOX pollution, resulting in less environmental impact, whilst maximizing the lifetime of the furnace.

At a cost of several thousands of dollars per furnace and re-tubing costs in the millions, a significant amount of capital can be lost, if a furnace failure goes unnoticed or if the refractory linings are retired too early or too late.

With the addition of special spectral filters the negative influences caused by burner firing can be avoided. Alternatively, a different setup of the camera with another spectral filter can be implemented, whereby the flame image is visible.

Dedicated Market Applications

For glass melting tanks, this is a critical tool to ensure that refectories remain intact and that the melting process is working at its optimum efficiency.

For petrochemical reformers, this is a critical tool to ensure tubes perform optimally for their longest possible life cycle.

In metal annealing applications, FurnaceSpection™ cameras have allowed users to significantly reduce cycle times while at the same time improving quality and process repeatability.

LumaSense Technologies has been developing industrial grade thermal imaging solutions for over 20 years, and have deployed custom systems around the globe to monitor critical processes and assets in power generation, refineries, steel, paper, and glass plants.