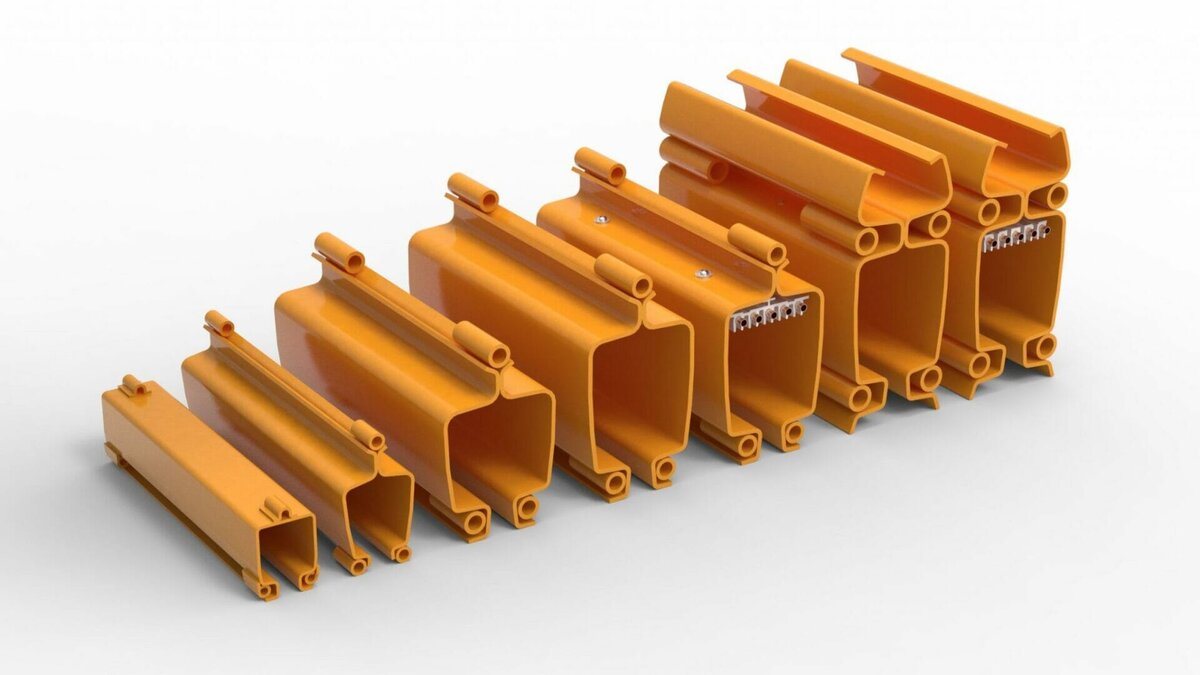

Verlinde announces the widening of its EUROSYSTEM overhead handling system range with new steel (STD) and aluminium (ALD) hollow profiles

EUROSYSTEM STD and ALD

VERLINDE EUROSYTEM STD (steel) and ALD (aluminium) profiles systems are now available thanks to the widening of the present range of EUROSYSTEM ST and AL hollow profiles. This new family of steel and aluminium profiles enables the design and manufacture of modular lifting systems such as runways, single-beam or double-beam overhead cranes to operate with Verlinde’s range of powered or manual chain hoists.

Verlinde’s EUROSYSTEM overhead handling system is designed to handle light loads of up to 2000 kg. Travel is effortless thanks to an excellent rolling coefficient and minimized strain on the bearing structure due to its pendulum type design. The system is modular and numerous configurations can be arranged to include monorails, runways, single-beam or double-beam suspended or encastred overhead cranes, telescopic beams and single or complete circuit systems, with points for changing the direction of travel or with a multi-direction turntable. All these combinations enable EUROSYSTEM to fully adapt to any site’s development or production process needs.

Reduced approach distances and the compactness of EUROSYSTEM STD and ALD components enable optimization of working space. This characteristic enables access for handling to non-rectangular spaces and to areas inaccessible to conventional systems. This great flexibility is enhanced even more by numerous types of mounting hardware that can be used across the whole structure.

New steel and aluminium profiles The basic component of the EUROSYSTEM STD steel overhead handling system is a special cold-formed hollow profile made from metal plates providing an extremely uniform surface. The rolling track surface evenness results in almost silent operations. 5 sizes are available in this range 2 of which have an integrated power supply.

EUROSYSTEM STD

EUROSYSTEM ALD in aluminium represents the new generation of handling systems using hollow profiles. This profile was made possible by the latest cold extrusion engineering innovations and optimisation of structures. The closed structure of the profile makes it possible to keep the inside of the runway clean. 4 sizes are available in this range, 2 of which have an integrated power supply.

EUROSYSTEM ALD

The two EUROSYSTEMS STD and ALD systems, whether they are assembled with steel or aluminium profiles, present similar advantages with benefits specific to their respective material as, for instance, the anticorrosive quality of anodized aluminium coupled with its amazing wear resistance.

As for STD and ALD, the selection of the model will depend on the load capacity and the distance between the suspension points. The ergonomics of the system and the lightness of the rails provide easy, effortless and highly precise manipulation by the user even with heavy and unwieldy loads. The closed structure of profiles keeps the inside of the roller path clean but also prevents any torsion of the hollow profiles and ensures manual or powered trolleys remain on the runway at the end of the roller path. Hollow rail assemby is achieved with connecting bolts and special guide connection pieces; profiles are furthermore guaranteed to be weld-free for maximum safety. The systems are economical thanks to the reduced volume and simplification of bearing structures combined with fast assembly.

VERLINDE: > Company born in 1858 > The leading French manufacturer and exporter of lifting and handling equipment. > A constantly-upgraded range of 30 groups of lifting equipment, designed for loads from 60 to 250,000 kg. ISO 9001 quality assurance certified and ISO 14001 EMS certified (environment management system).

In France: EUROPONT travelling crane construction plants, a sales network, a distributor network and after sales facilities.

Abroad: > An advisory service in more than 92 countries.

For more information, visit www.verlinde.com.

VERLINDE SAS 2, Bd de l’Industrie BP59 28501 Vernouillet Cedex Jean-Yves BEAUSSART Phone: +33 2 37 38 96 26 /06 07 53 10 43