The mechanical engineering industry needs to consistently meet the growing need for special tools and solutions. However, the industry is also faced with increasing competitive pressure, which is causing manufacturers to permanently examine and optimise their production processes in order to hold their ground in today’s competitive market.

What about Tool storage with automated shuttle systems?

Machine tools are used across a wide range of industries processing materials of all kinds. They are primarily used by companies in the metalworking sector or businesses involved in toolmaking and the automotive industry.

Regardless of whether forming machines are used to process steel, aluminium, or plastics, cutting machines are used for processing materials such as wood and special high-performance tools are constantly required during the manufacturing process. When not in use, these tools have to be stored in a number of different ways. Storing the parts in special tool cabinets is certainly the most common way. The tools are frequently stored in several tool cabinets and boxes of various sizes distributed throughout the entire production area. This inconvenient arrangement takes up valuable space, not to mention the fact that the parts are difficult to access.

Yet as the challenges associated with a changing market steadily grow, so do the demands in relation to efficiency and costs in the area of internal tool storage. The use of modern manufacturing structures in production goes hand in hand with rising intralogistic market demands for

All of this means that the pressure in relation to increased efficiency also grows on conventional storage methods. After all, apart from the relatively convenient form of storage in static tool cabinets, this form of storage can only make a small contribution to improving productivity.

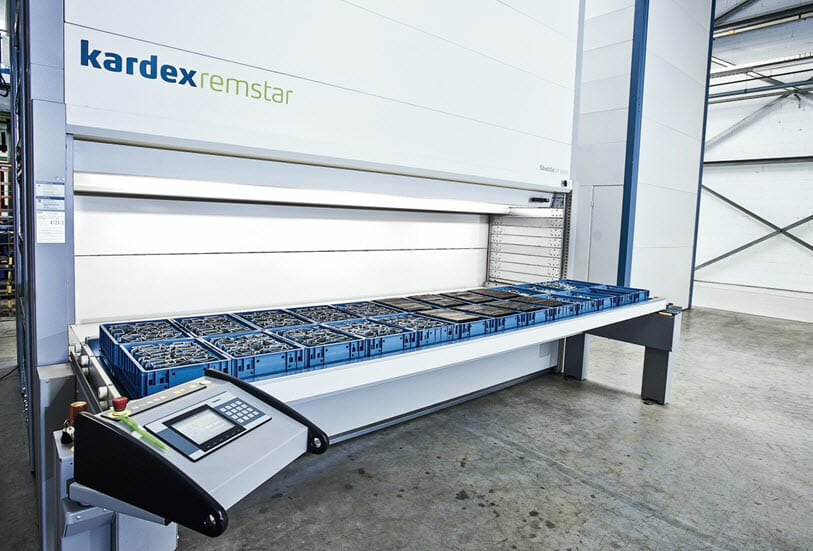

Significant improvements can be made in this area simply by introducing a central tool store with the help of an automated storage lift such as a shuttle. The accommodation of various tools in a few different types of boxes or tool holders with precisely tailored dimensions brings further advantages, because optimal use can be made of the depth and height within the storage space.

In addition, it is often the case that the instruments and tools used are extremely sensitive. Accordingly, besides ensuring fast and accurate access to the stored tools, there is a focus above all else on safe and clean storage. Modern storage lift systems also have an advantage here, because the parts can be placed in compartments precisely adapted to their specific dimensions on the trays, thereby limiting the contact these sensitive parts have with their surroundings from the outset. In addition, there are special devices in the shuttles which guarantee dust-free and especially dry storage. Storing the tools at a certain temperature or drying them with warm air is also no problem. These are all options that conventional shelf-based storage cannot offer.

Furthermore, dynamic systems such as automated storage lifts give the user many more opportunities to optimise the efficiency of their intralogistics processes. Faster and more accurate access to the stored parts is but one example that speak in favour of this modern storage method.

Further advantages include:

- significantly less walking around for employees thanks to the goods-to-person principle

- fast and accurate access to stored goods, controlled by warehouse management software, avoids unproductive search times and increases picking accuracy to over 99 percent

- the use of warehouse management software also permits accurate monitoring and management of the entire storage process

- optimal use is made of the room height and space in the building

- the ergonomically designed workspaces, which work according to the goods-to-person principle, cut the amount of time that employees are absent from work

It is therefore no wonder that ever more companies involved in tool storage are now switching to automated storage lift systems to manage their intralogistics processes even more efficiently.

You can find out more about the various storage options afforded by modern shuttle solutions here. Or contact Kardex direct on 0844 9390800 or email us at: [email protected]