Two key factors are demanded of bearings used in wind energy systems: high performance and high service life under harsh conditions. This observation is especially the case in the offshore segment, where the capacities of wind turbines are still increasing. As a result, NSK recently commenced the manufacture of bearings for 9.5 MW turbines and is already developing bearings for offshore turbines in the 12 MW class.

However, it is not just the performance capabilities that place high demands on wind turbine bearings. At sea, because of high wind speeds, even stronger static and dynamic loads act on the rotors and, consequently, the whole drive train. In onshore wind turbines, the main bearings undergo loads of up to 1 MN; in the case of offshore turbines, it is even more.

Service life expectations rise

Increasing demands are being placed on the operating lifespan of bearings for wind turbines. For onshore turbines, manufacturers traditionally specified that bearings must be designed for a service life of 175,000 hours, which is equivalent to 20 years. However, as a result of the high investment costs and difficulty in accessing offshore wind energy systems, a service life of 25 years is specified, which is a major challenge considering the extremely high dynamic loads.

Main bearings

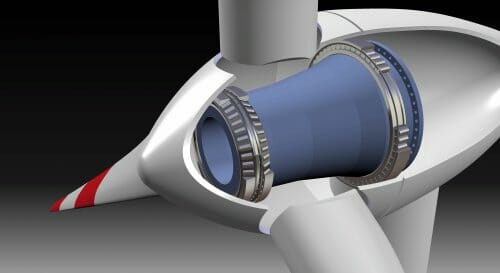

These loads clearly have an influence on the choice of bearings. In direct-drive wind turbines, double-row tapered roller bearings are increasingly being chosen as the main bearing. Compared with cylindrical roller bearings, which were commonly specified in the past, tapered roller bearings offer the advantage of adjustable pre-load, which makes it possible to achieve higher system rigidity. Such bearings have inner diameters of up to 2.7 m, which challenges even state-of-the-art design and manufacturing concepts.

In the case of geared systems, the weight of the additional drive components is compensated by the fact that the generator can have a smaller design. There are different design concepts for the main rotor bearing in each power capacity class. Systems up to 5 MW usually employ spherical roller bearings, while for 6 MW and higher, the preference is for arrangements with two tapered roller bearings, or double-row tapered roller bearings combined with a cylindrical roller bearing.

Integrated bearings

In geared drive trains, gearboxes with two or three-stage planetary stages are common nowadays. Often these planetary stages are combined with a helical gear stage. For several years, the trend has been towards using so-called integrated planetary gears. For this application, NSK has developed (in close co-operation with the gear manufacturer) multi-row tapered and cylinder roller bearings without an outer ring. Thus, the bore of the planet wheels is used as the outer raceway of the bearing.

In some applications, four-row integrated cylindrical roller bearings are used. In combination with four planets per stage, one set of bearings includes a total of 16 rows. To obtain an even load on all bearings, the bore and circumscribed diameters for the whole set have very tight tolerances.

Another trend is to source all the bearings for a turbine from a single supplier. This market tendency was one of the specific reasons why NSK decided to expand the product portfolio of its Wind Business Unit, although the company has already been developing and manufacturing various types of bearings for gearboxes and generators for 20 years.

Researching WEC (white etching cracks)

Due to the size of the bearings required for offshore wind turbines and difficult accessibility, the wind industry is obviously very sensitive to bearing damage. Technical expertise makes it possible to overcome almost all typical forms of damage to bearings. For example, advanced design methods in combination with high levels of steel purity ensure that classical bearing fatigue failures have been practically eliminated in wind turbine bearings.

One area that the bearing industry is still researching, however, is WEC (white etching cracks). These cracks are signs of bearing damage that appear relatively early in the bearing’s service life. Typical damage symptoms are white structures beneath the raceway (hence the name) that lead to the formation of cracks and, ultimately, bearing failure.

The precise cause of WEC was unknown for a long time, and although a series of experiments has since shown that this defect is most likely caused by hydrogen penetration, the origin of the hydrogen has still not been fully explained.

Further research works hint that hydrogen generation occurs during operation. The initial supposition was that the hydrogen was coming from the hydrocarbon chains of lubricants and their additives; a theory that was substantiated after typical damage symptoms were able to be reproduced in a laboratory with certain types of oils and greases.

As a consequence, NSK developed a new material that demonstrates higher resistance to hydrogen penetration and the formation of cracks caused by hydrogen embrittlement. While laboratory tests have been successfully completed, bearings made of this material are currently undergoing field trials.

Applying condition monitoring

As a result of the fail-safe characteristics and long service life requirements, the bearings in wind energy systems are ideal candidates for condition monitoring systems (CMS), which use externally mounted or integrated sensors to continuously monitor the state of the bearing. Anomalies that indicate damage to the bearings can be detected and reported in a timely manner.

Modern-day CMS are deployed by offshore wind farms to detect abnormalities sufficiently early to allow the maintenance cycle of the system to be planned accordingly. NSK anticipates significant market potential for this type of system.

B092018-N-Image2.jpeg – A major trend in the wind turbine industry is the integration of planetary gear stages and multi-row bearings

B092018-N-Image3.jpeg – NSK has offered an extensive portfolio of wind turbine bearings for over 20 years

B092018-N-Image5.jpeg – Bearings can be equipped with externally mounted or integrated sensors and linked to CMS (condition monitoring systems)

About NSK

Established 100 years ago, NSK (Nippon Seiko Kabushiki Kaisha) is a Japanese-listed company that has evolved from a regional ball bearing supplier to a roller bearing specialist and automotive supplier with a global market presence. Today, NSK employs more than 31,860 employees in 30 countries. As per March 2018 NSK achieved a turnover of 1020 billion Yen. This result has been driven by ever-increasing investment in research & development, enabling the company to continuously improve the quality of its products and services. This investment supports NSK’s objective of “No. 1 in Total Quality”. In addition to a complete rolling bearing portfolio, NSK develops and manufactures precision components and mechatronic products, as well as systems and components for the automotive industry, including wheel bearing units and electric power-steering systems.

In 1963, NSK’s first European subsidiary, Düsseldorf, Germany, was opened and in 1976, the first European production facility in Peterlee, England. Today, NSK Europe supports pan-European sales with production locations in England, Poland and Germany, logistics centres in the Netherlands, Germany and England and technology centres in Germany, England and Poland. In 1990, NSK purchased the UPI Group including the renowned European bearing manufacturer RHP, with its factory in Newark (UK). Additionally, NSK has developed a comprehensive network of authorised sales distributors. NSK Europe is divided into application-based business divisions: Industry rolling bearing technologies & linear and precision technology (EIBU) as well as bearing modules and steering systems for the automotive industry (EABU & ESBU). In this organisation, NSK Europe\’s 3,900 employees achieved a turnover of over 1,056 million Euros as per March 2018.

For more information, visit www.nskeurope.com

NSK Deutschland GmbH

Harkortstrasse 15

40880 Ratingen

Germany

PILATH Marie-Dominique

Phone : +49 2102 4810

Fax : +49 2102 4812290

pilath-m@nsk.com