The drastic change in water levels that characterise dams requires ship lifts (or lift locks) to transport boats and ships between the different elevations in a short time. These advanced engineering solutions need high-quality, durable and reliable brakes to support the ship chamber at any height and prevent machinery overloading. One of the largest ship lifting facilities worldwide is able to ensure optimal performance by applying state-of-the-art braking equipment from Stromag.

The Goupitan reservoir dam, located on the Wujiang River in southwest China’s Guizhou province, is among the tallest in the world at 232.5 m in height. It hosts one of the largest hydroelectric power stations ever built, featuring a generating capacity of 3,000 MW. This massive construction, operated by Guizhou Wujiang Hydropower Development Company, required a large and efficient lift lock that would allow boats and small ships to move past the dam easily and quickly.

The system, developed by Changjiang Institute of Survey, will lift vessels up to 1,800 tonnes in weight via three lifting stages: each stage lifting the vessel 79 metres. The decision to break the lifting into three stages maximises the boat transportation efficiency, helping to handle the busy boat traffic without causing congestion. The three stages each comprise a gate and separate ship chamber, meaning that three vessels can occupy the lift system at any one time. Each elevator consists of two rows of hoist cable drums and the gearboxes are positioned over both sides of the boat-lifting reservoir. This design provides a hoisting speed of approximately 8 meters per minute, thus can raise or descend a 500-tonne vessel (the estimated average weight of passenger boats) in 10 minutes, slashing the travel time past the dam.

This difficult and complex civil engineering project needed a braking solution able to address a number of challenges. First, the equipment should withstand the unusually heavy weights occurring when hoisting the ship chambers and the boats on them. In addition, the brakes needed to fit into the limited, confined spaces of the lift towers: the components would be pedestal-mounted on the hoist drum brake discs of each elevator.

In order to address these challenges, Changjiang Institute of Survey chose Stromag, one of Altra Industrial Motion Corps. premier brands, as its supplier of braking systems for this ambitious project. Stromag is well known for its innovative power transmission components and has extensive experience in the manufacture and supply of braking solutions for ship lifting applications. In particular, Stromag was involved in the construction of the Strépy-Thieu boat lift in Belgium, the world’s second tallest lift lock, as well as in a number of similar projects across China, including the Silin, Shatuo and Yantan dams.

Michel Donnay, Plant Director of Stromag’s French facility, commented: “China is one of the largest and most challenging market for ship lifting applications, hosting some of the most notable lifting infrastructures. Stromag’s contribution to some of the largest ship elevators worldwide attests to the quality of our braking equipment. Also, we have an in-depth knowledge of the governing guidelines and standards in China, which is why the company has been selected by a number of demanding projects in the country.”

Stromag worked alongside Changjiang Institute of Survey and the end user, Guizhou Wujiang Hydropower Development Company, to analyse the application requirements and the opportunities provided by different braking system. In this way, they were able to select the most suitable alternative: the SH32 hydraulic disc brake.

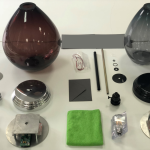

This robust spring applied caliper brake is specifically designed for heavy-duty lifting and is able to provide dynamic braking forces up to 334kN. The brakes also feature a compact design that fits into applications with limited space available. In addition, this solution is easy to operate, and its extensive reliability makes it is economical to maintain.

To further optimise the system, the SH32 brakes needed to be coupled with a number of hydraulic power packs with touch-screen control interfaces, also supplied by Stromag. These would allow the control system to easily adjust and apply a braking force in a controlled, progressive way, providing optimal performance and maximum equipment service life.

An anomaly resulting from the scale of the dam was the number of brakes required for the project: the vertical locking mechanism required more than twice the number of brakes than other ship lifts that Stromag had supplied in China.

In order to supply the large volume of SH series brakes and power packs in a timely manner, and ensure building operations stayed on schedule, Stromag’s engineering teams in China and France worked together to manufacture and perform real-world tests on the products in a short time frame. This close collaboration enabled its engineers to complete the project in only twelve months, despite the extensiveness of the engineering project and the large volume of brakes required.

Michel concluded: “The extensive ship lift project at Goupitan dam was successful thanks to an efficient cross-divisional team work within Stromag. Our global presence, also backed by the broad network of experts within Altra’s family, allows us to combine experts from all over the world in order to complete a project in a timely manner and without jeopardising our manufacturing lines.”

Besides delivering state-of-the-art equipment, Stromag offered a continuous engineering partnership that supports its customer throughout the equipment life cycle. More precisely, ship lift operators have the chance to thoroughly understand the braking system via operation and maintenance training offered by Stromag. Also, specialised teams within Stromag and Altra are available to inspect, conduct maintenance services, repair and renovate the equipment in order to extend the service lives of SH 32 brakes and hydraulic power packs.

The slipway at Goupitan dam was completed in late 2017 and is now the tallest in the world. The busy boat traffic on the Wujiang navigation channel will require the infrastructure to operate seamlessly, as any stopping or delay of the ship lift could cause large traffic congestions and affect the industries across the river. Stromag’s SH 32 brakes, designed for heavy duty lifting, will provide an efficient and reliable solution able to contribute to the optimal performance of the ship elevator at Goupitan dam.

Designed for heavy duty lifting the SH 32 brakes will provide an efficient and reliable solution able to contribute to optimal performance of the ship elevator at Goupitan dam.

To further optimise the system, the SH32 brakes needed to be coupled with a number of hydraulic power packs with touch-screen control interfaces