As part of a re-design project to reduce both costs and the total weight of the vehicle, a well-known crane manufacturer faced the challenge of eliminating a second engine. The original machine was fitted with a main drive engine and a separate crane engine, which powered the lifting mechanisms. With the secondary engine eliminated, the power required for the superstructure would be derived from a power take-off using the distributor gear. The driving torque required would then be transmitted via gear shafts to the hydraulic unit used to lift the superstructure.

However, when the new design configuration was tested, severe vibration was encountered in operation. An innovative coupling solution would be required to remedy this issue, however no space provision had been made in the new design for a coupling. The challenge presented to REICH-KUPPLUNGEN engineers therefore, was to devise a compact customer-specific solution that also exhibited the torsional stiffness required. A challenge indeed, although not impossible to accomplish.

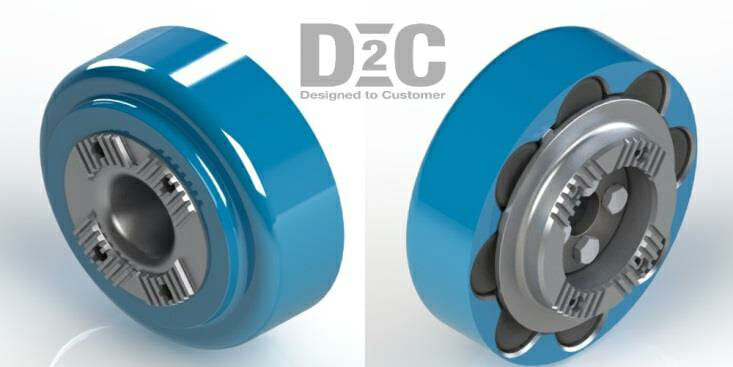

In this instance, the solution would require a compact coupling, capable of dealing with a wide torque band, ranging from the torque generated at idle speeds through to that produced under full power conditions. The solution to the challenging criteria for this application came in the form of REICH’s GUR 45-8 drive coupling. The low stiffness characteristics exhibited by the coupling in the lower load range ensures that torsional vibrations are kept below critical levels at no-load speed.

(The GUR 45-8 is particularly suited for applications where loads tend to increase in line with rotational speeds)

However, thanks to the progressive nature of this coupling type, the stiffness of the coupling rises as torque transmission increases. This is why the GUR 45-8 is particularly suited for applications where loads tend to increase in line with rotational speeds.

Although the perfect solution in this instance, the versatile characteristics of the GUR 45-8’s, design mean it can be used in a variety of applications. A broad range of special rubber qualities ensures that this coupling can also be used at very high ambient temperatures. The GUR 45-8 is a robust rubber roller coupling featuring a fail-safe device. From a maintenance perspective, individual rubber elements can be replaced quickly and easily, without the need for special tools. Just pull the plugged coupling apart and insert the rollers radially from the outside into their specially shaped recesses. The GUR coupling series is available for different power ranges, and, in line with the D2C “Designed to Customer” philosophy, customization to suit specific applications is a matter of course for REICH-KUPPLUNGEN.

The GUR 45-8 and a wide range of other coupling solutions will be on show in hall A4, stand 514, Bauma, the worlds leading construction machinery trade fair from 8 – 14 April 2019 in Munich.

With a history spanning over 70 years, REICH-KUPPLUNGEN has built up unrivalled expertise in the design and manufacture of drive couplings for use across a wide range of industries and applications. The company has earned an enviable reputation not only for the quality and performance of their product range, but also for their ability to provide application and customer specific solutions through the company’s D2C (Design to Customer) philosophy.

For more information please contact:

Mr David Proud

General Manager

Reich Drive Systems UK Limited

Unit 4, Bankside Business Park

Coronation Street

Stockport

Cheshire

SK5 7PG

Telephone +44(0) 161 714 4191

Website – www.reich-uk.com