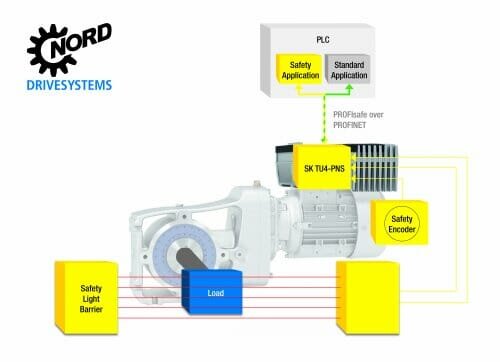

Functional safety of plant and machinery is of vital importance in production. The NORD SK TU4-PNS option module from NORD DRIVESYSTEMS assists the simple implementation of safe responses. In combination with a safety PLC, the drive electronics reliably communicate over the existing PROFINET via PROFIsafe.

Functional Safety is becoming increasingly important as a fundamental component of modern machine and plant design and it is an indispensable aspect of the drive systems from NORD. At present, NORD DRIVESYSTEMS supplies frequency inverters with integrated STO and SS1. The drive specialist provides fail-safe communication and safe movement functions according to IEC 61800-5 with the SK TU4-PNS PROFIsafe module. Functions such as SLS (Safety Limited Speed), SSR (Safe Speed Range), SDI (Safe Direction), SOS (Safe Operation Stop) and SSM (Safe Speed Monitor) can be integrated and expand the drive units’ safe stop functions. With this, the PROFIsafe interface module provides comprehensive safety for the reliable operation of plant and machinery.

Reliable communication of safety-relevant data

PROFIsafe is the world’s leading and generally used technology for safety applications for production and process automation. With SIL3 and PLe (Performance Level e) Category 4, the fail-safe communication protocol fulfils the most stringent safety requirements. The PROFIsafe fail-safe protocol extension for PROFINET enables standard and fail-safe information to be transmitted with integrated functional safety between the higher level machine or the plant control system and the NORD drives in a single network cable. Elimination of conventional hard-wired safety technology reduces the amount of wiring and therefore reduces costs Furthermore, networking via PROFIsafe makes extensive safety-relevant machine data accessible and globally available.

Operate drives safely

The PROFIsafe bus interface SK TU4-PNS monitors safe compliance with the limit values and provides safe inputs and outputs. If a limit value is exceeded or undershot, the bus interface switches to a safe state. The voltage is disconnected from all outputs, input information is reset and transmitted to the higher level fail-safe controller. This is essential for the use of the PROFIsafe module.

Integration of safety functions into the drive unit offers many advantages in comparison with a drive solution with discrete safety technology. Less installation space is required, the number of external safety components is fewer and the system is modularly scalable. The amount of wiring is reduced to a minimum as only a network cable is required. Another advantage is the global availability of the security-related machine data.

NORD: PROFIsafe module for increased safety

Meta description:

The option module SK TU4-PNS fulfils the most stringent safety requirements and ensures secure communication in PROFINET environments. Find out more!

Keywords: NORD DRIVESYSTEMS, intralogistics, drive technology, drive electronics, LogiDrive, geared motor, geared motors, PROFIsafe, PROFINET, functional safety, safe communication, communication protocol, safety, safety functions, frequency inverter, NORDAC, PLC, inverter

Deeplink: https://www.nord.com

Social media

LinkedIn profile: https://www.linkedin.com/company/getriebebau-nord-gmbh-&-co-kg/

LinkedIn links: @Getriebebau NORD GmbH & Co. KG

Twitter: https://twitter.com/NORD_Drive

Twitter links: @NORD_Drive