A new series of linear motion modules from Ewellix has been launched to transform the capabilities of industrial robots, extending their reach and footprint.

Ewellix, formerly SKF Motion Technologies, has launched a new series of linear motion modules designed to increase significantly the capability of small industrial automation robots and cobots. The company’s new LIFTKIT and SLIDEKIT can extend the reach and mobility of standard robots without the need for expensive upgrades or complex accessories and programming. The new modules are supplied ready to install and can typically be fully operational in just 30 minutes.

The LIFTKIT comprises a telescopic pillar, capable of raising and lowering a standard robot or cobot by up to 900 mm; in some applications, this can be extended still further. Three versions of the LIFTKIT are available: the TLT for light loads and long distances; the CPMT for heavier loads; and the CPSM for high speeds and positional accuracy to within ±0.01 mm. These are ideal for all pick and place and palletising applications where additional height is required.

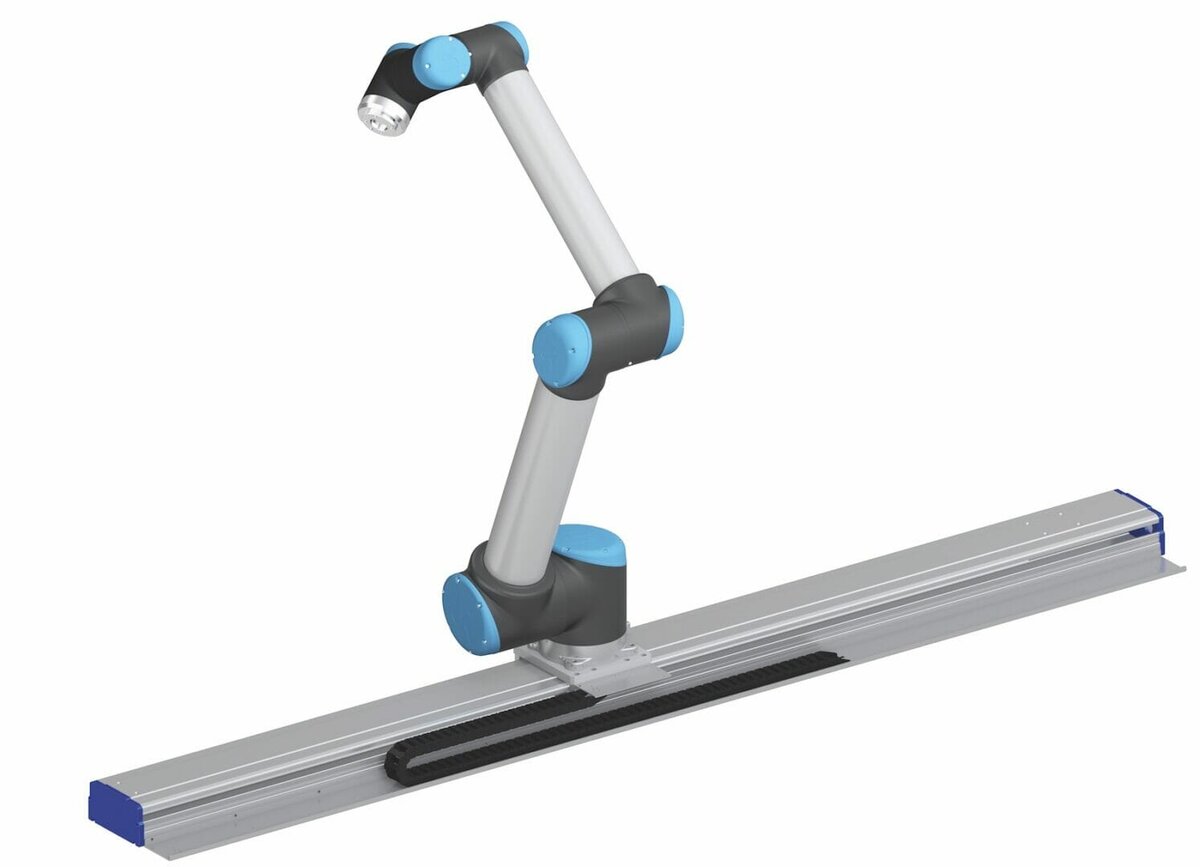

For applications where extended horizontal movement is required, the SLIDEKIT enables the reach of each robot to be increased by up to 1,800 mm. The SLIDEKIT is based on a standard Ewellix’ profile rail guide, combined with an advanced ball screw in a single integrated unit, to ensure extremely accurate positioning and repeatability.

The LIFTKIT and SLIDEKIT are robust and reliable. They can also be combined to create an exceptionally versatile system at extremely competitive cost. Ewellix also offers the option to build customised versions. The KITS are also available as plug-and-play solutions for use with all robots manufactured by Universal Robots (UR). These versions are supplied with all hardware, attachments, control units and interfaces for quick and simple installation.

Damien Ehry, Global Business Support Manager at Ewellix, sees considerable time and cost advantages, especially for OEMs and medium-sized industrial companies. “The LIFTKIT and SLIDEKIT are plug-and-play systems, which include all the necessary mechanical and electrical interfaces to the UR robots, enabling the end customer to use the system immediately. A medium-sized company that sets up two to three robotic cells with collaborative robots can become productive almost immediately without any development effort.”