Turin, November 10, 2019

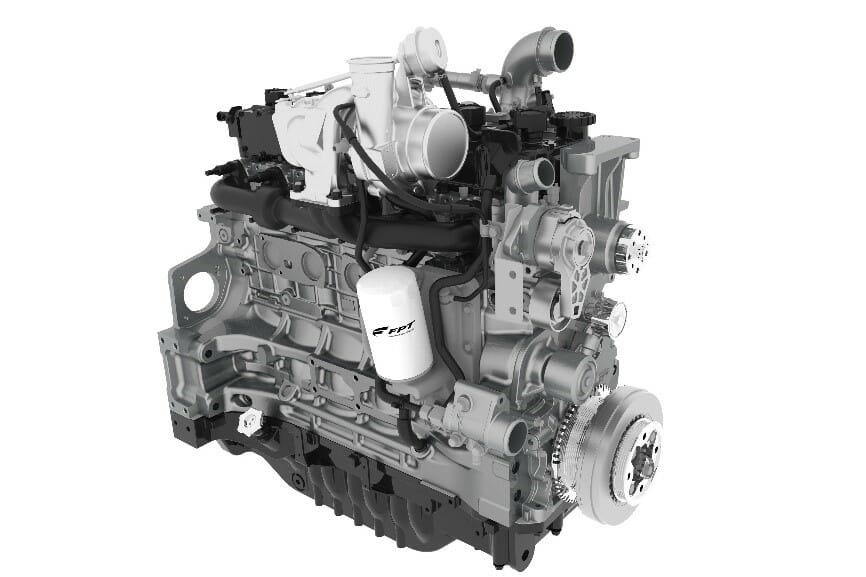

As part of its continuous commitment to sustainable powertrain solutions, FPT

Industrial presents the N67 Natural Gas engine specifically developed for off-road

applications. With this launch, which takes place at Agritechnica, in Hannover,

Germany, the Brand leverages its vast experience in Natural Gas (NG) engines to

lead the introduction of this technology in agricultural and construction machinery. As

a matter of fact, thanks to the launch of the F28 Natural Gas, FPT is the first manufac-

turer to have a series of low and mid-range Natural Gas engines for agriculture.

The N67 Natural Gas is exhibited at stand C34 – Hall 16. With a displacement of 6.7

liters and a six cylinder in-line configuration, the new engine offers Diesel-like

performance in agricultural applications, delivering power of 180 kW at 1,800 rpm and

torque of 1,035 Nm at 1,500 rpm.

Compatible with Compressed Natural Gas (CNG), Liquefied Natural Gas (LNG) and

biomethane, the N67 NG has 10% lower CO2 emissions than Diesel engines in real field

conditions. When running on biomethane, this can reach virtually zero or even become neg-

ative, contributing to a new circular economy free from waste and fuel costs, that can lead to

completely efficient and productive agriculture.

Natural Gas also results up to 98% less Particulate Matter (PM) and 48% less NOx when

compared to Diesel. All these environmentally friendly benefits have been proven by the over

50,000 FPT Industrial Natural Gas units sold to date worldwide, and are the outcome of its

more than 20 years’ experience in this technology. The Brand currently holds 70% European

market share for Natural Gas engines for goods and people transport and is also the

manufacturer with the widest range of gas engines.

The N67 NG engine has a robust off-road-oriented design, with high performance materials

and structural configuration for fitting on tractors, ensuring durability and reliability. Stoichio-

metric combustion and multipoint gas injection ensure stable and clean combustion for high

efficiency and low emissions. Finally, it also has reduced running costs in comparison to

Diesel, service interval of 600 hours and a maintenance-free 3-way catalyst as its after-treat-

ment system to comply with the latest emissions standards.

N67 Natural Gas Stage V

Architecture: In-Line 6-Cylinder Engine

Injection System: Multipoint injection

Air Handling: Wastegate

Valves Per Cylinder (Number): 4

Displacement (l): 6.7

Max Power (kW): 180 kW @ 1,800 rpm

Max Torque (Nm): 1,035 Nm @ 1,500 rpm

Oil Service Interval: 600 hours

ATS: 3-way catalyst