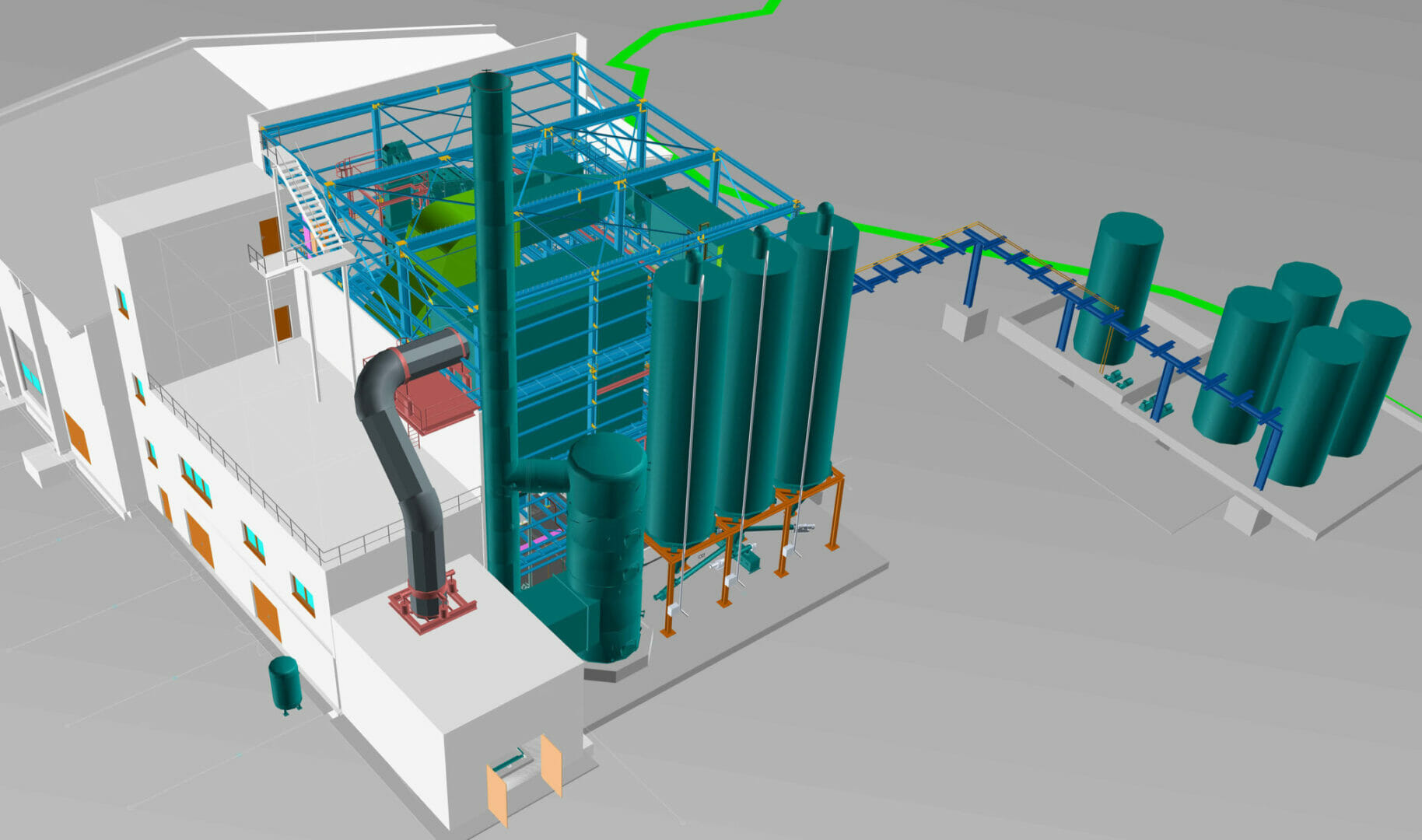

The company collaborated with renowned plant constructor and process expert, Glatt Ingenieurtechnik from Weimar, to jointly develop innovative technology for this unique-in-Germany plant. This involves the recovery of phosphorus from sewage sludge ashes and its residue-free conversion into standard fertilisers according to the Fertiliser Ordinance. Glatt was also in charge of planning and implementation, from raw material supply — via suspension processing and subsequent fluidised bed granulation — to the finished fertilizer.

Seraplant is investing €20 million in this innovative production facility at Haldensleben with support from the state of Saxony-Anhalt and will create more than 20 new jobs. The project will be supported with almost €5 million of finance from the “improvement of the regional economic structure” joint funding programme.

Production is planned to start in the fourth quarter of 2020. The plant is designed for an annual production of 60,000 tonnes of phosphate fertilizer, with end users expected to be conventional and organic agricultural businesses, agricultural and horticultural wholesalers as well as the fertilizer industry.

The entire process is completely waste-free. No dangerous intermediate products, residues or exhaust gases are produced during the process. The project thus makes a significant contribution to the sustainable use of the vital resource: phosphorus. Although Germany has no natural phosphorus deposits, this process is now making indigenous resources available again, avoiding the need to import this coveted nutrient.

Legislation will make the recovery of phosphorus from sewage sludge mandatory in the near future. As such, operators of large sewage treatment plants are looking for alternatives that enable these requirements to be met today.