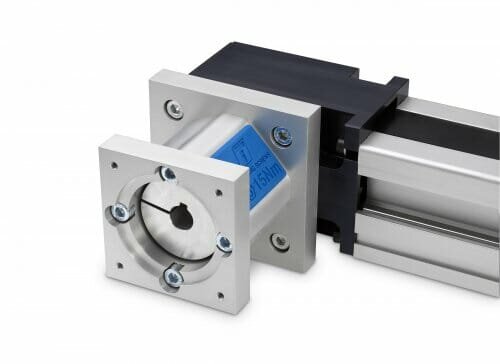

Recently upgraded and now the default assembly solution across Thomson Industries’ wide range of linear motion systems, the simplified RediMount™ adapter system is a key component that enables quick and effortless motor/actuator installation. Widely used by Heason Technology, an automation partner for Thomson and a leading UK-based systems integrator and manufacturer of motion control solutions, the RediMount comprises of a flange and flexible coupling assembly for electric motor driven actuators or gear units and is available for more than 500 servo, stepper and other motor-types from dozens of manufacturers.Selection of the appropriate RediMount adapter is made simple with Thomson’s Linear MOTIONEERING product sizing and selection tool – used to calculate the optimised combination of linear actuator or gear unit with an appropriate motor. Available via Thomson Linear, the tool will generate the dimensional detail for the RediMount adapter as part of the bill of materials for manufacture. The Linear MOTIONEERING tool can optionally include the customer’s preferred motor and will check if its performance will meet the specifications of their application. This way the adapter can be shipped pre-installed with the actuator/gear unit allowing the optimal motor to be used for straightforward assembly without the need for further design effort and cost.

The RediMount adapter system is the default assembly solution across a wide selection of Thomson linear actuators that are available with full support from Heason Technology and have well proven use in custom-designed systems used across applications in aerospace, automotive, defence, robotics, process, packaging, medical technology and more. The innovation helps the West-Sussex based motion systems specialist and its OEM supply chain customers to maintain minimum delivery times and reduce inventory levels.

Precision and performance characteristics for Thomson linear actuators range from transport grade linear units used in packaging and materials handling to ball-guided high precision units with the stiffness and rigidity that suits machine tool and high duty cycle automation. Belt driven units for high speed/high throughput pick and place and packaging systems are also covered. In addition, rod-style precision linear actuators find use in materials handling, machining and factory automation applications where they are an ideal and compelling alternative to hydraulic and pneumatic cylinders.

Heason Technology has its own in-house design and production capability and matches products from distribution partners to provide customised motion control and automated positioning systems solutions. For more information visit www.heason.com or email [email protected].