To support the circular economy of plastics, igus has invested £4 million in Mura Technology Limited that wants to put the first commercial Catalytic Hydrothermal Reactor (Cat-HTR) plant into operation. The technology recycles plastic waste into oil within 20 minutes, which can be reused to make new plastic products.

- Every year, 8 million tons of plastic end up in the oceans.

- This lost resource is estimated to be worth around £60 billion.

- Most plastics are incinerated and only 14 percent recycled.

The first commercial Cat-HTR-plant is currently being planned in Wilton, Great Britain, and construction is to start this year. Waste companies supply the waste plastic to meet their recycling goals. Oil is then obtained that can be sold as a replacement for virgin fossil oil. A total of four catalytic hydrothermal reactors are to be built in Wilton and will be able to process more than 80,000 tons of plastic waste every year. As a next step, Mura is planning to issue licences all over the world and build new plants

The patented Catalytic Hydrothermal Reactor was developed in 2007 and tested for over 10 years in a pilot plant in Australia. With Cat-HTR, classic non-recyclable plastic waste can be converted back into crude oil within 20 minutes – it is more resource efficient than the extraction of fossil fuels out of the ground.

Only water, high temperature and pressure are used to separate the cells and join them together again. One plant alone can process 20,000 tons of plastic per year, reducing CO2 output by 28,180 tons. This corresponds to the annual consumption of 5,983 cars or the annual energy requirements of 4,914 households.

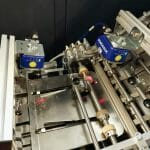

Plastic recycling is an important topic at igus. The introduction of its chainge program last year allows companies to send their end of life plastic cable management systems, or energy chains, to igus for recycling – irrespective of the manufacturer. The plastics are then sorted, cleaned, shredded and packed. After this, the plastics can be reused by igus or other companies to produce high-quality technical products.

“With the igus chainge program, we are recycling plastics from old products. This is the best way for high-performance, or technical, plastics,” says Frank Blase, Managing Director of igus. “For non-technical plastics, chemical recycling offers a new solution. In the middle of the year, I became aware of the Catalytic Hydrothermal Reactor technology in an article in the FAZ and contacted the German inventor Professor Thomas Maschmeyer in Sydney. Seven months later, after intensive research, we are investing £4m in Mura Technology Limited and the construction of the first Cat-HTR plant. We are committed to the achievement of a state of balance in the world of plastics with technical solutions.”

igus UK strives to save energy and reduce the waste of production materials wherever possible and is proud to be ISO 14001 accredited; this helps igus on its way towards becoming a carbon-neutral factory. To read more about the environmental work igus is doing please visit: www.igus.co.uk/info/sustainability or call igus directly on: 01604 677240

For more information about Cat-HTR technology: https://www.youtube.com/watch?v=dGx4m0KiFac