Galvanometer scanners offer high speed laser scribing, but are inherently limited by their field of view, which is often no more than a 100 mm by 100 mm square. Consequently, there is growing interest in combining high speed laser galvanometer scanners with larger motion platforms to enable flexible laser machining processes.The galvanometer scanner is typically isolated from the controls for the machine stage, and the two platforms must work together in a step-wise manner. The stage moves the scribing surface to an appropriate position under the galvanometer scanner, and signals that scanning can begin. Once this operation is completed, the process is repeated until the entire design has been scanned. This process – often described as ‘step and scan’ – has a number of drawbacks. The start and stop nature of the process, as well as the difficulty in controlling two systems founded on different principles, is inefficient. Close examination of laser-scribed lines also reveals breaks or stitching errors at junctions where the scanning has had to be carried out in two separate steps.

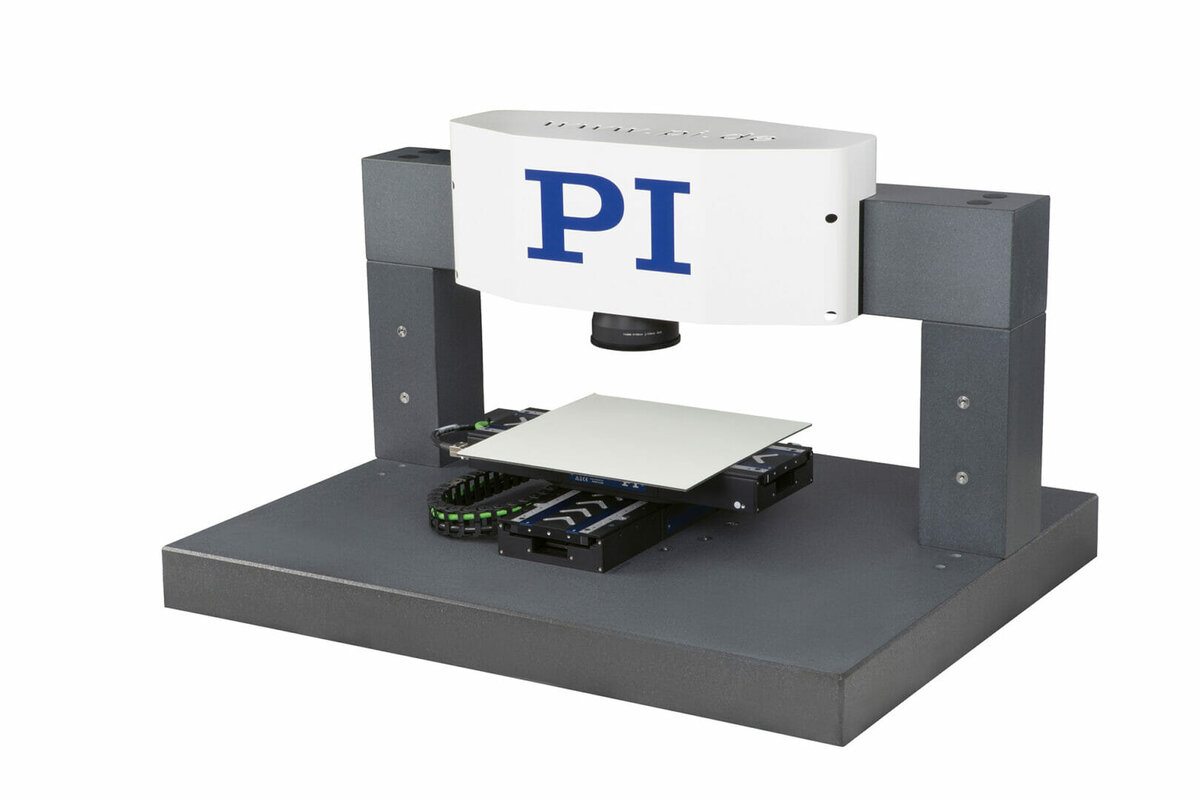

A collaboration between PI (Physik Instrumente), ACS Motion Control and SCANLAB GmbH has developed a novel solution – XLSCAN (eXtra Large Scan). The new process combines the operation of the two instruments into a single, integrated platform, allowing simultaneous control and movement of the galvanometer scanner and the xy-stage. This effectively overlays the small field of view of the scanner with the longer travel of the stage, and enables continuous scanning without stitching errors. Throughput is also markedly increased – up to 41 per cent more in some instances – and the zero following error of the galvanometer scanner delivers the highest accuracy in the market for such a system.

PI in brief

Over the last 40 years, Karlsruhe-based Physik Instrumente (PI) has become the leading manufacturer of nanopositioning systems and products based on piezo technology. PI is a private company with more than 900 employees worldwide and a flexible, vertically integrated organisation, enabling it to fulfil almost any request in the precision positioning technology field. All PI’s key technologies are developed in house, allowing class-leading precision mechanics – screw, direct drive, linear, rotary, air and mechanical bearings – and associated electronics, position sensors and piezo ceramics or actuators to be guaranteed from design to shipment, whether standard or customised. Piezo ceramics and actuators are produced by PI Ceramic, a subsidiary of PI, and the company has its own sales and service offices in all major markets. PI also maintains testing devices for nanometrology on three continents, and both PI Shanghai and PI USA have additional development and manufacturing resources, allowing rapid local response to specific customer needs.