MACH 2020, Hall 20 Stand 563

MACH will not only enable Starrag UK to promote all the product ranges marketed under the Starrag brand -– including the recently-enhanced Heckert range of affordable four-/five-axis horizontal machining centres as well as live cutting on a Bumotec s191 mill-turn centre – but it will also allow the company’s new Sales Manager, Phil Roberts, to be introduced to the hordes of visitors expected at the NEC.Phil, whose role will include focusing on customers in Starrag’s target areas of industrial and transport, energy and medical devices, brings to Starrag UK more than 20 years’ experience in production engineering and machine tool sales, especially in developing solutions for complex turning and multi-axis milling applications.

That skill set aligns perfectly with Starrag’s maxim of ‘Engineering precisely what you value’, which has consistently set the bar in terms of its partnerships with clients using machines and technologies from the Starrag range of machines from Berthiez, Bumotec, Dörries, Droop+Rein, Ecospeed, Heckert, Scharmann, SIP and Starrag.

Importantly, Starrag’s continued success at companies of every size and in all industry sectors has been built on providing machining solutions tailored for individual customer needs. These solutions can involve stand-alone machines or flexible manufacturing systems with varying levels of automation and incorporating Industrie 4.0 strategies.

The new-look Heckert machines are prime examples of how Starrag develops solutions to meet specific needs, with these machines having been designed on a modular basis and able to be specified exactly to meet users demands (in terms of, for example, spindle speeds and pallet sizes) in the most cost-effective manner.

Boasting traverse rates up to a staggering 80 m/min, the machines not only have a smaller footprint of up to 30% less than traditional horizontal machines, which results in an estimated 15% increase in productivity per unit area, but they also boast:

[] Acceleration rates of 1.2 g,

[] Tool change (chip-to-chip) times down to 2.2 secs, and

[] Pallet change times down to 8.5 secs.

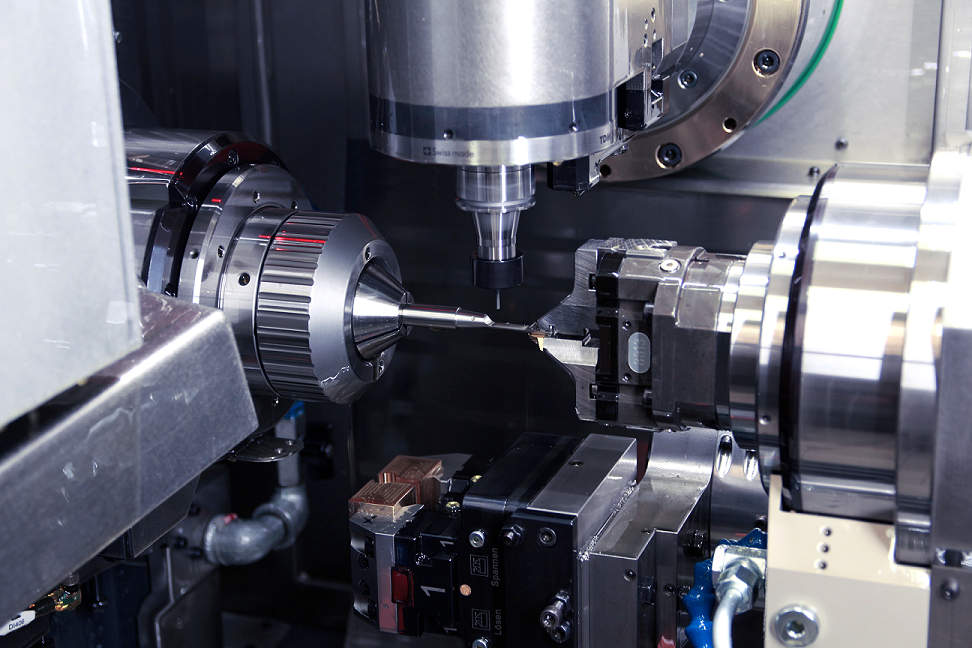

Also on the stand, a Bumotec s191 mill-turn centre will be machining medical industry components throughout the exhibition, showcasing its ability to also undertake drilling, thread forming, grinding, gearcutting and broaching, for example, in a single set-up.

The machine will highlight how it can achieve highly accurate (to +/- 2.5 microns) machining solutions within its X, Y and Z axes range of 410 mm, 200 mm and 400 mm, respectively, courtesy of linear drives and high-level thermal stability.

Its main spindle is complemented by a sub-spindle that can turn in both horizontal and vertical planes, for multi-process/tasking routines, and tool magazine options extend to up to 90 pockets on a machine that has rapid traverse rates of 50 m/min and a 30,000 (or 40,000) revs/min spindle speed that also contribute to its ultra-fast cycle times.

Visitors to the stand will also be able to learn about Starrag UK’s rental scheme for the Bumotec s181 and s191 machines, providing potential users with a cost-effective way to capitalise on the benefits of multi-tasking, single set-up machining. The scheme allows customers to avoid relatively high upfront capital expenditure yet immediately benefit from the machines’ ability to drastically reduce lead times by completing a range of different tasks in a single setting.

Lee Scott, Starrag UK Director for Sales and Applications, says “visitors to MACH may well be surprised – and pleased – at how affordable and available these machines are”!

The Heckert X40 has X, Y and Z axes travels of 700 mm by 750 mm by 750 mm and can accommodate workpiece heights of 500 mm and loads of 400 kgs