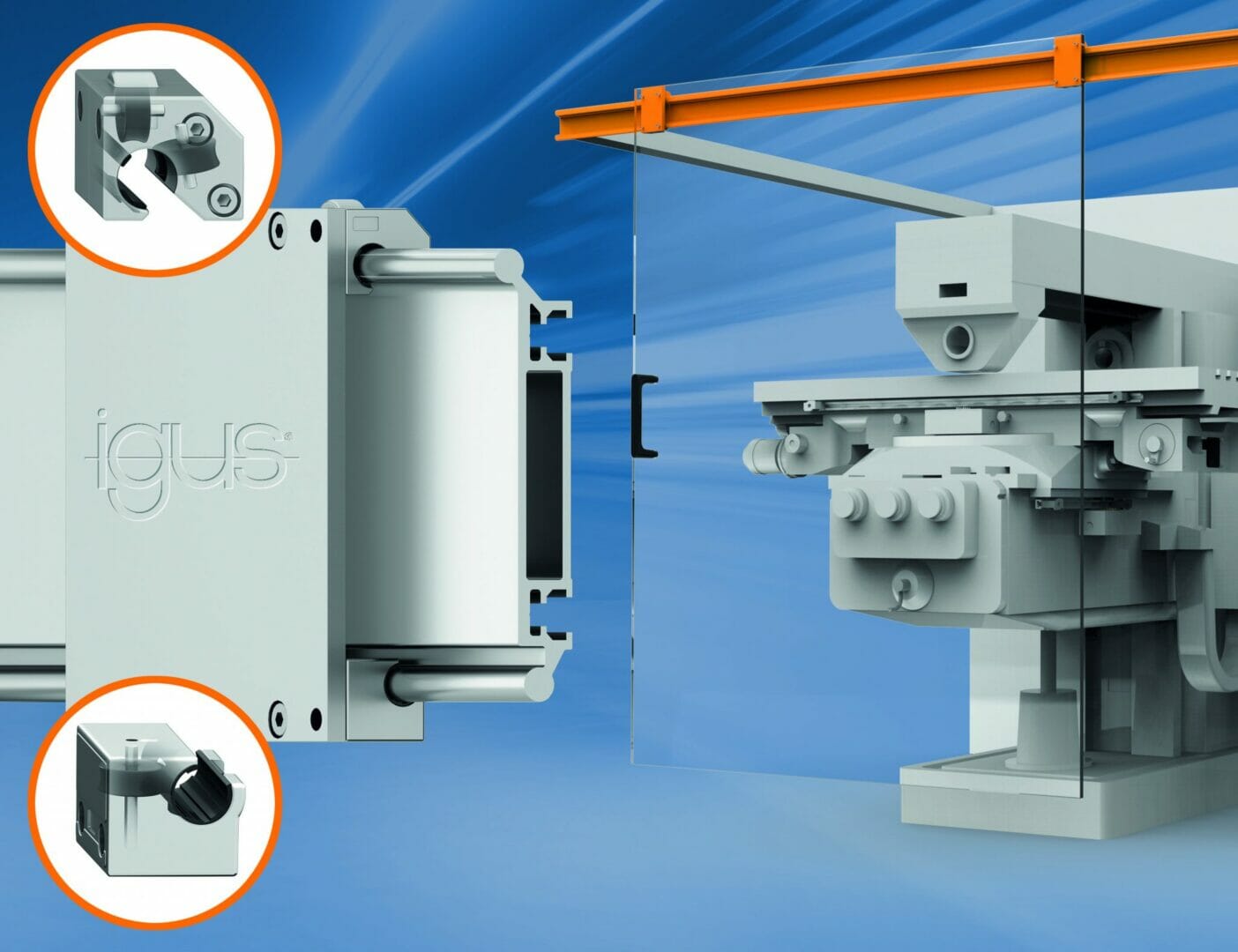

Linear systems are extensively used to move doors, monitors or even panels laterally, or side-to-side. If a low driving force is required, especially for manual adjustments, rollers are often used in the bearing element to reduce friction. However, to absorb the lateral forces, the position of these rollers is crucial. As a solution, igus has introduced two new hybrid roller bearings, which offer smooth adjustment with low drive forces and maximum support.The WJRM-41-10 has two offset polymer rollers with optimised alignment for better force absorption and easier rolling. The hybrid roller bearing WJRM-31-10 with single roller is in turn the matching, supporting bearing on the opposite side. By using the two roller bearings together, the coefficient of friction can be halved while increasing the service life of the application.

In both bearings, in addition to the rollers, there are sliding elements made of the low-friction tribo-polymer iglidur J. The lubrication-free and maintenance-free material is characterised primarily by its low coefficient of friction. Both bearings can be positioned at the desired bearing clearance.

Using a top plate, the two new roller bearings can be added to a linear guide. To ensure that the bearings can also be used on the matching guide, igus has developed a low-profile hybrid roller rail. This has a special geometry optimised for the hybrid roller bearings. The rail has a simple design without visible holes and is able to attach from the back with sliding blocks. This makes the new rail in combination with the hybrid roller bearings ideal for lateral installations.

For more information about the new hybrid bearings, please visit: www.igus.co.uk/drylin/linear-guide